Composition for anisotropic pigmented film, anisotropic pigmented film, and polarizing element

An anisotropic and polarizing element technology, applied in optical elements, polarizing elements, nonlinear optics, etc., can solve the problem of increased drying deformation, difficulty in combining high coating uniformity and productivity with high dichroism, dichroism Lowering and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

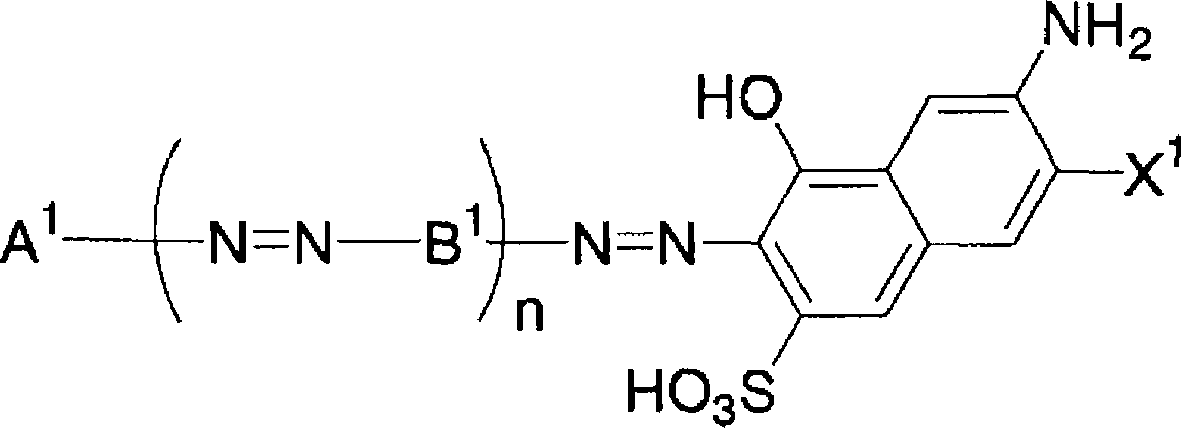

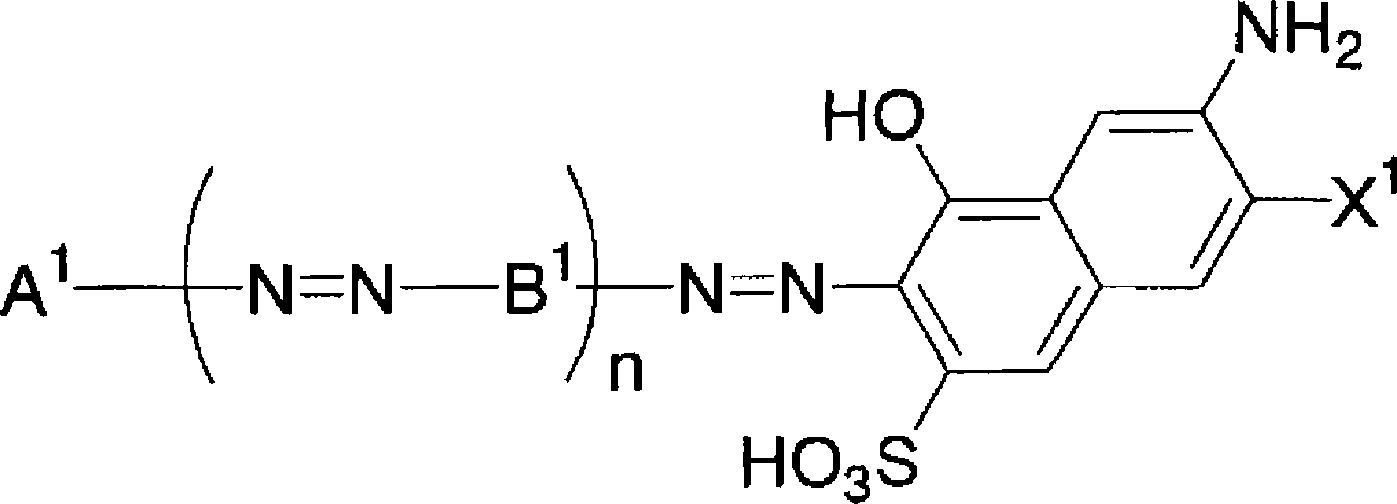

Method used

Image

Examples

Embodiment 1

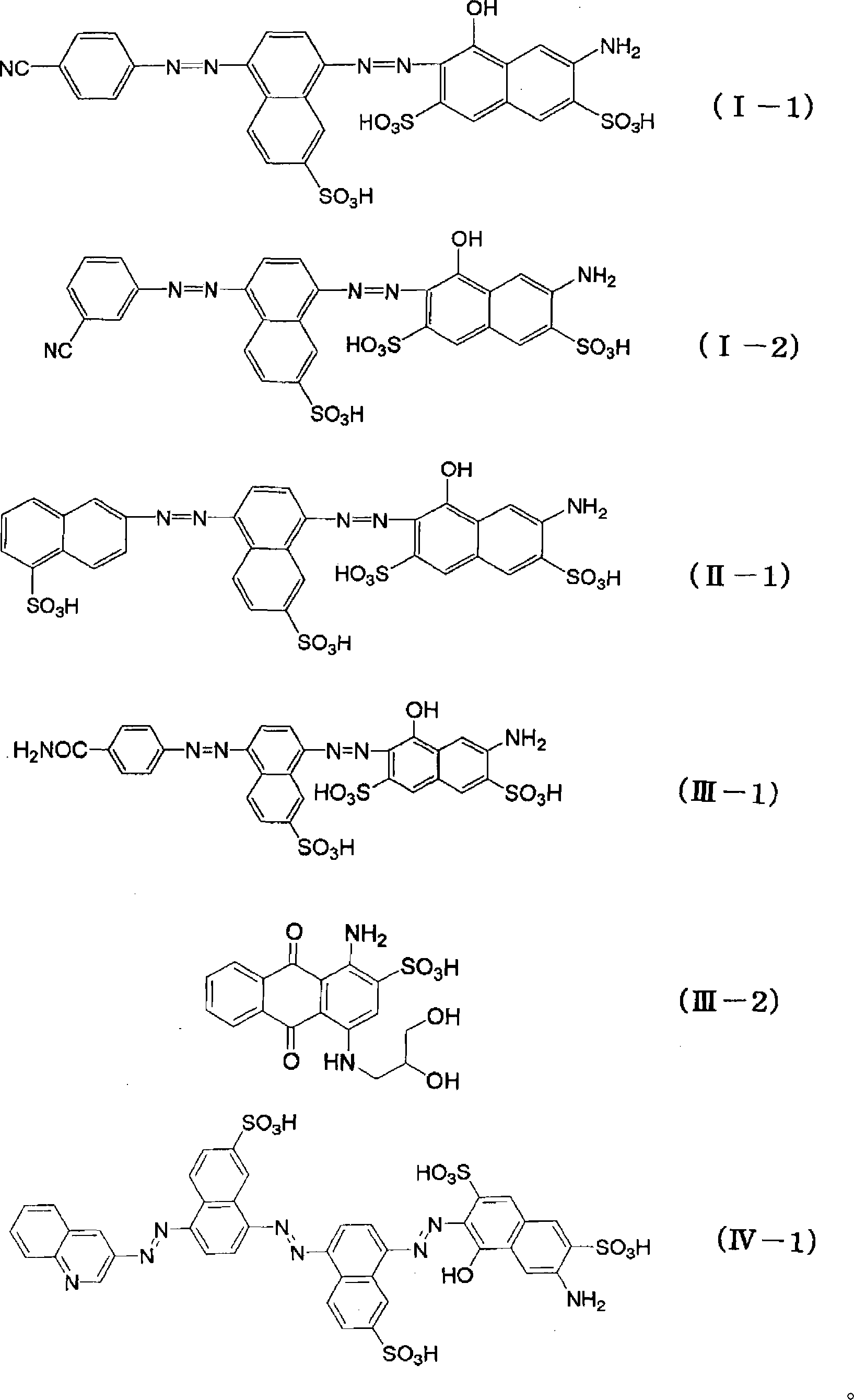

[0163] 20 parts of the lithium salt of the dye No. (I-1) exemplified above were stirred and dissolved in 80 parts of water, and filtered to obtain a composition for anisotropic dye film.

[0164] For this anisotropic pigment film composition, the relaxation modulus G measured at a temperature of 5° C. for 0.01 seconds after straining was 9.2×10 1 dyn / cm 2 , the time taken for the relaxation modulus G to decrease to one-tenth is 0.04 seconds, which is shorter than 0.1 seconds.

[0165] A polyimide alignment film (thickness about 800 Ȧ) is formed on a glass substrate (75 mm x 25 mm, thickness 1 mm) by screen printing, and the substrate is rubbed with a cloth in advance to prepare such a substrate in advance. , the above-mentioned composition for anisotropic pigment film was coated on it using a coater with a gap of 2 μm (four-sided coater manufactured by Imoto Manufacturing Co., Ltd.), and then dried in a vacuum to obtain an anisotropic dye film with a film thickness of 0.4 μm....

Embodiment 2

[0168] 30 parts of the lithium salt of the dye No. (II-1) exemplified above and 1 part of 4,5,6-triaminopyrimidine sulfate (manufactured by Tokyo Chemical Industry Co., Ltd.) were stirred and dissolved in 69 parts of water, and filtered to obtain anisotropic Composition for pigmented film.

[0169] For this anisotropic pigment film composition, the relaxation modulus G measured at 5° C. for 0.01 seconds after deformation was applied by the above-mentioned method was 1.8×10 4 dyn / cm 2 , the time taken for the relaxation modulus G to decrease to one-tenth is 0.05 seconds, which is shorter than 0.1 seconds.

[0170] This composition for an anisotropic dye film was coated on the same board|substrate as Example 1 by the same method as Example 1, and the anisotropic dye film was obtained.

[0171] Defects and cracks were not observed on the obtained anisotropic dye film. And the dichroic ratio at a wavelength of 550 nm was 30.

Embodiment 3

[0173] In 78.94 parts of water, stirring and dissolving 15 parts of the lithium salt of the pigment No. (I-1) exemplified above through desalting and refining, 5 parts of the 80 mol% lithium neutralization salt of the pigment No. (I-1) exemplified above, 1 part of Alizarin Red S manufactured by Aldrich and 0.06 part of lithium chloride after desalination and refinement were filtered, and the composition for anisotropic pigment films was obtained.

[0174] For this anisotropic pigment film composition, the relaxation modulus G measured at a temperature of 5° C. for 0.01 seconds after straining was 9.9×10 1 dyn / cm 2 , the time for the relaxation modulus G to decrease to one-tenth is 0.04 seconds, which is shorter than 0.1 seconds.

[0175] This composition for an anisotropic dye film was coated on the same board|substrate as Example 1 by the same method as Example 1, and the anisotropic dye film was obtained.

[0176] Defects and cracks were not observed on the obtained anisot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com