Elastic abrasive cloth and abrasive wheel

An elastic and abrasive cloth technology, applied in the field of grinding wheels, can solve problems such as overall scrapping, and achieve the effects of high fitting precision, cost reduction, simplicity, convenience and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 is an elastic emery cloth with a convex circular arc, which is produced by the following process:

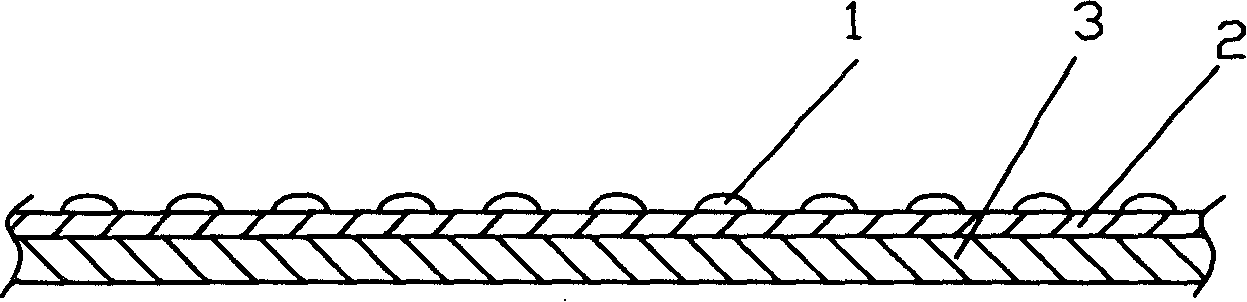

[0036] 1 Select elastic modified plastic as the raw material of elastic layer 3; diamond or cubic boron nitride and brittle resin are used as abrasive grains 1, and the bottom of the abrasive grains is placed into the base cloth 2;

[0037] 2. Abrasive cloth making: the base cloth with abrasive grains 1 is formed into a ring by rubber-plastic molding method and elastic layer 3

[0038] The emery cloth can also be evenly bonded on the elastic layer 3 by applying glue to form an annular emery cloth.

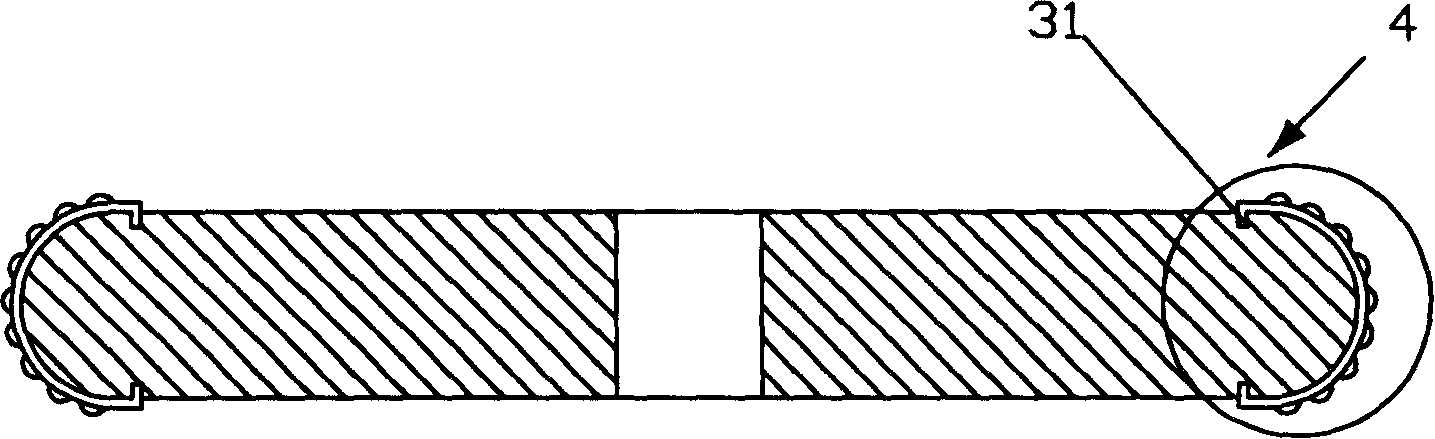

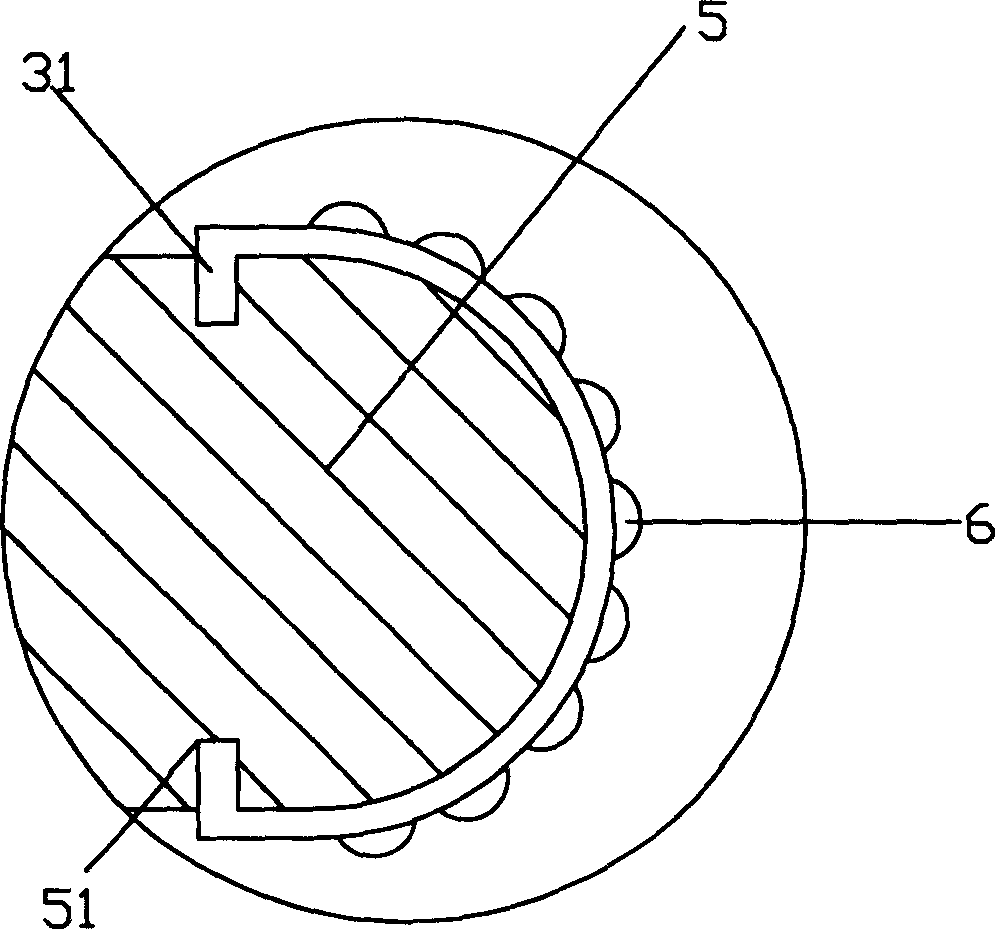

[0039] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, the shape of the convex circular arc annular elastic gauze 4 is the same as the shape of the outer edge of the support base 5, its size is slightly smaller than the size of the outer edge of the support base 5, and a raised ring is arranged at the two ends of the elastic layer 3 31 is respe...

Embodiment 2

[0041] Embodiment 2, is the emery wheel of roller shape, and its processing process is as follows:

[0042] Material selection: silica gel is used as the elastic layer 2, cotton cloth is used as the base cloth 2, and silicon carbide particles are used as the abrasive grain 1;

[0043] 2. Abrasive cloth making: evenly bond the abrasive grains 1 to the base cloth 2, and cut them into emery cloth strips with the same width as required;

[0044] 3. Forming: put the cut emery cloth strip into the mold, inject silica gel to form the elastic layer 3, make the emery cloth strip with abrasive grains 1 and silica gel integrally formed, and form the elastic emery cloth 7 in the shape of a roller;

[0045] 4. Set: Set the roller-shaped elastic emery cloth 7 on the supporting base 8 to form a roller-shaped elastic grinding wheel.

[0046] Such as Figure 6 , 7 As shown in and 8 , a protruding ring 31 is provided at both ends of the elastic layer 3 of the roller-shaped emery cloth 7 , an...

Embodiment 3

[0047] Example 3, such as Figure 9 with 10 shown. It is a drum-shaped elastic emery cloth, and the elastic emery cloth 9 is set on the supporting base 10 . Can be used to grind and polish various surfaces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com