Method and system for modifying HC discharge of engine when starting

An engine and cold start technology, applied to engine components, combustion engines, machines/engines, etc., to achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1 A method for improving HC emission during cold start of an engine, the main steps are: 1. Take fresh air and inject it into the passage behind the exhaust valve of the engine; 2. When the exhaust valve is opened, the fresh air directly carries out oxidation reaction with the exhaust gas; 3. The exhaust gas enters the three-way catalytic converter for catalytic conversion. The specific solution is that the secondary air pump pumps fresh air from the air filter, passes through the secondary air valve (the ECU determines the amount of air injection), and then distributes the air to both ends of the cylinder head by a special structure and enters the exhaust manifold. The air groove on the pipe (the four-cylinder machine adopts the method of injecting two by two), and a hole is drilled at the same position on the cylinder head, which leads to the exhaust valve, the air groove on the exhaust manifold and the hole on the cylinder head The holes are directly conne...

Embodiment 2

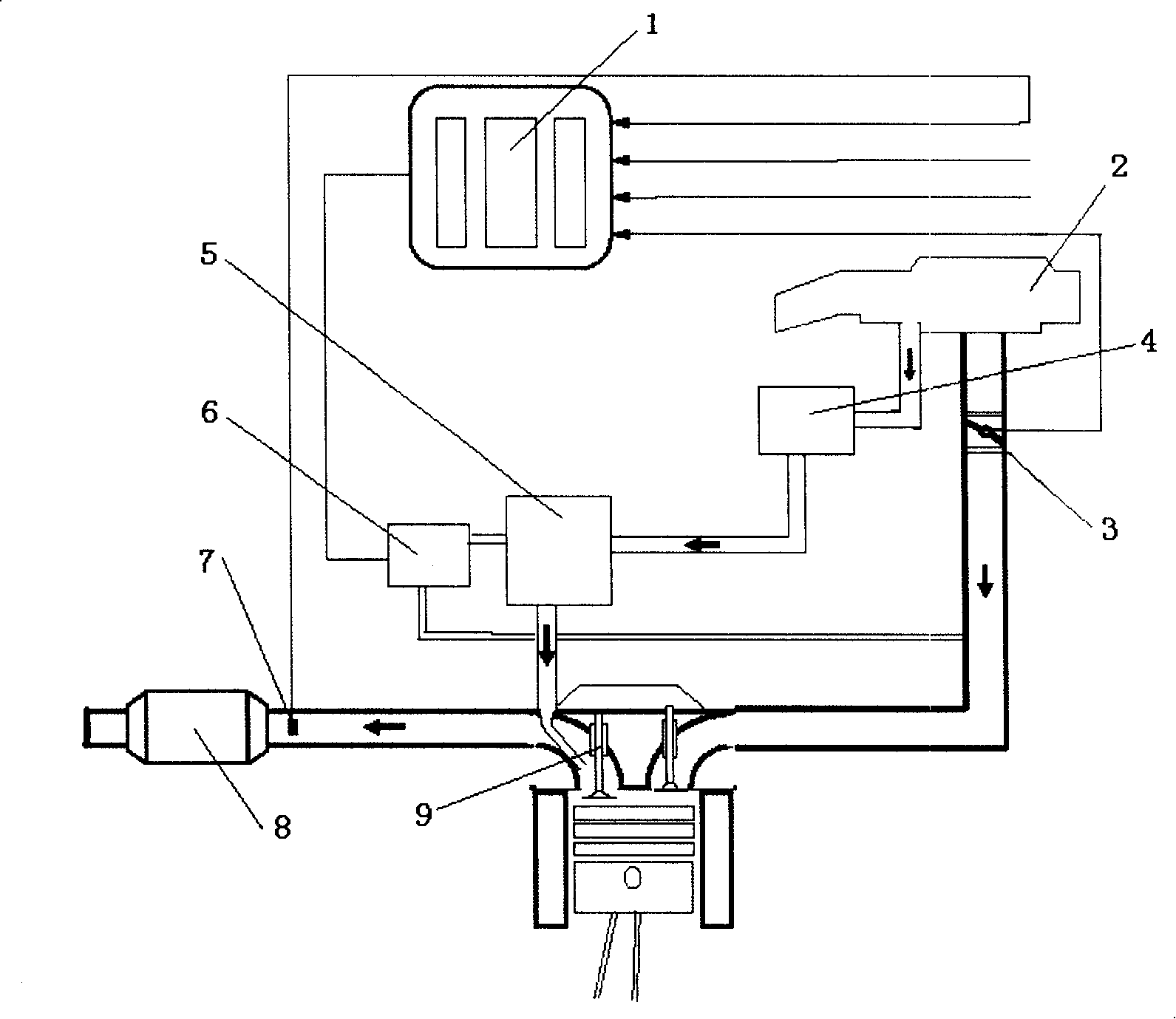

[0014] Example 2 as figure 1 As shown, a system for improving HC emission when the engine is cold started, including a secondary air pump 4 that takes air from an air filter 2 and is connected to a secondary air valve 5 inlet controlled by a solenoid valve 6, an oxygen sensor 7, and a three-way catalyst 8 and an electronic control unit (ECU) 1; the pipeline behind the engine exhaust valve 9 is connected to the three-way catalytic converter 8; an oxygen sensor 7 is arranged in front of the three-way catalytic converter 8; the electronic control unit 1 is electrically connected to the solenoid valve 6 and the oxygen sensor 7 ; It is characterized in that: the outlet of the secondary air valve 5 is connected to the exhaust valve 9 of the engine.

[0015] The electromagnetic valve 6 is a vacuum valve, which takes vacuum by connecting the intake manifold pipeline. The electronic control unit 1 is also electrically connected to and controls the throttle body 3 on the intake pipelin...

Embodiment 3

[0016] Embodiment 3 A system for improving HC emission when the engine is cold started, the rear outlet of the secondary air valve 5 is connected to the exhaust valve 9 of the engine. This is done by milling an air slot in the exhaust manifold and drilling a hole in each exhaust port on the exhaust side of the cylinder head that communicates with the air slot on the exhaust manifold. Then the fresh air is pumped in by the secondary air pump 4, and the fresh air is evenly distributed into the exhaust air passage by the air groove on the exhaust manifold, and finally the purpose of directly injecting fresh air into the exhaust passage is realized. All the other, with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com