Joint for resin pipe

A resin tube and resin technology, which is applied in the direction of pipes/pipe joints/fittings, pipe connection layout, mechanical equipment, etc. The effect of release performance, easy cost, high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

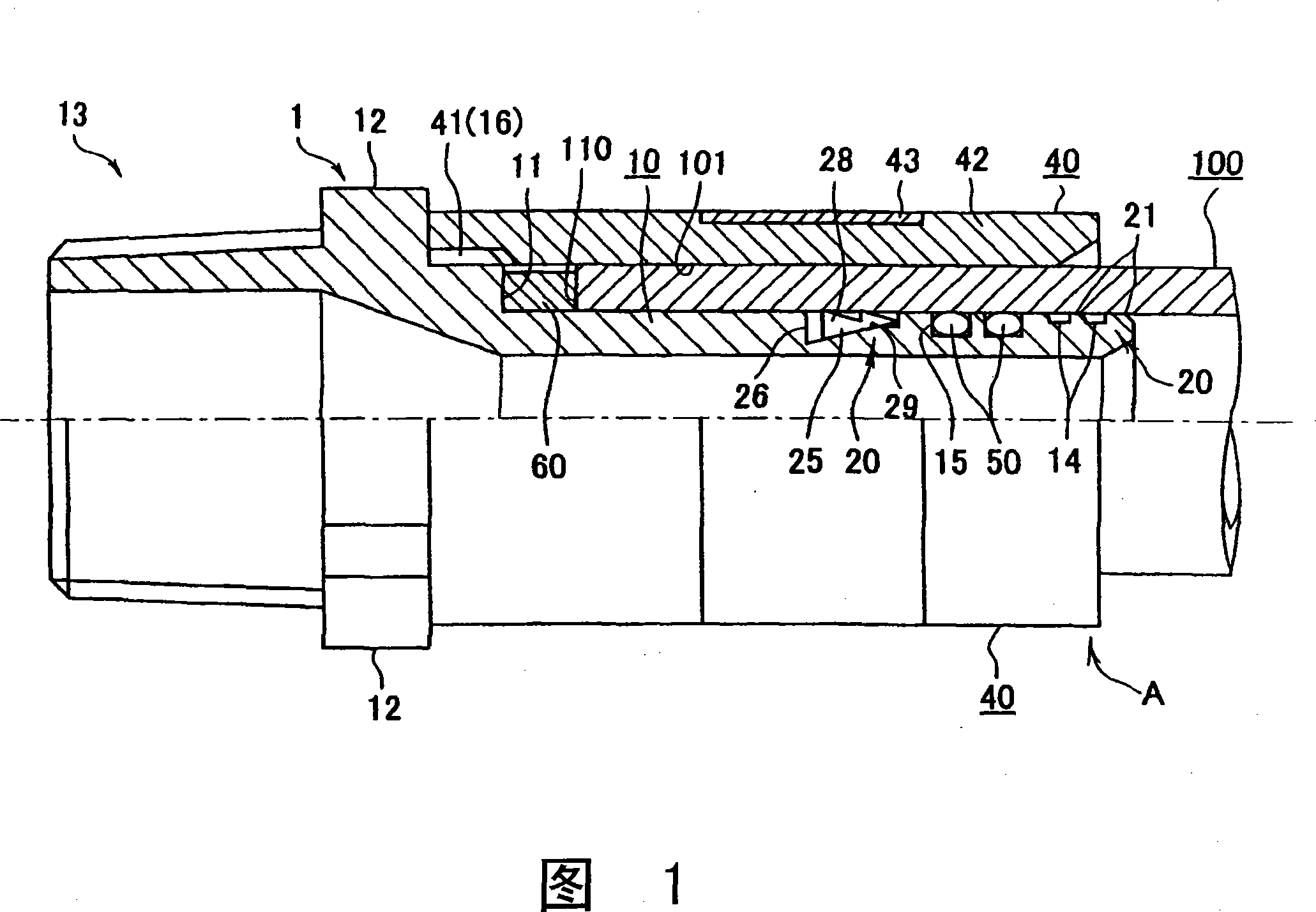

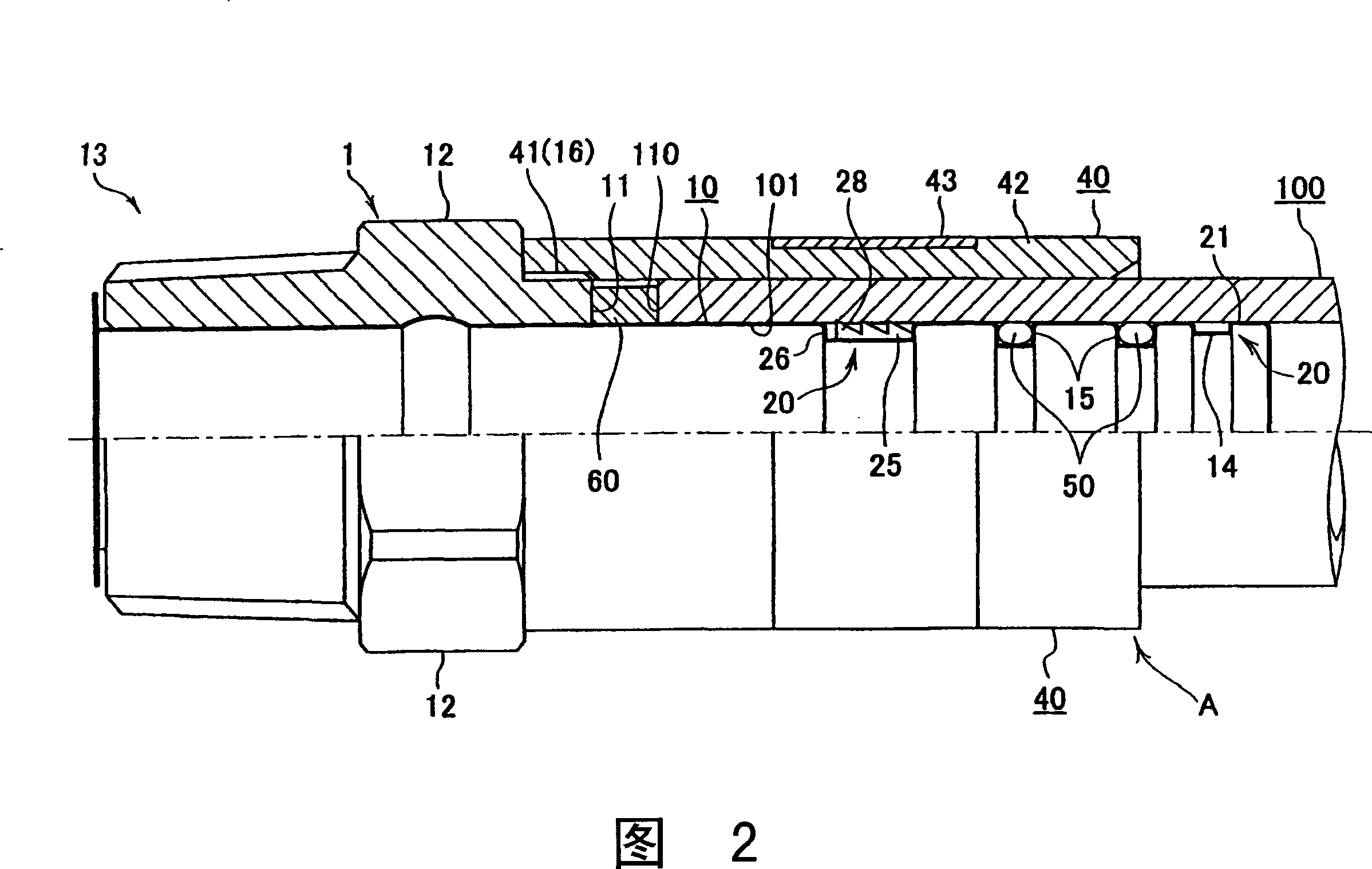

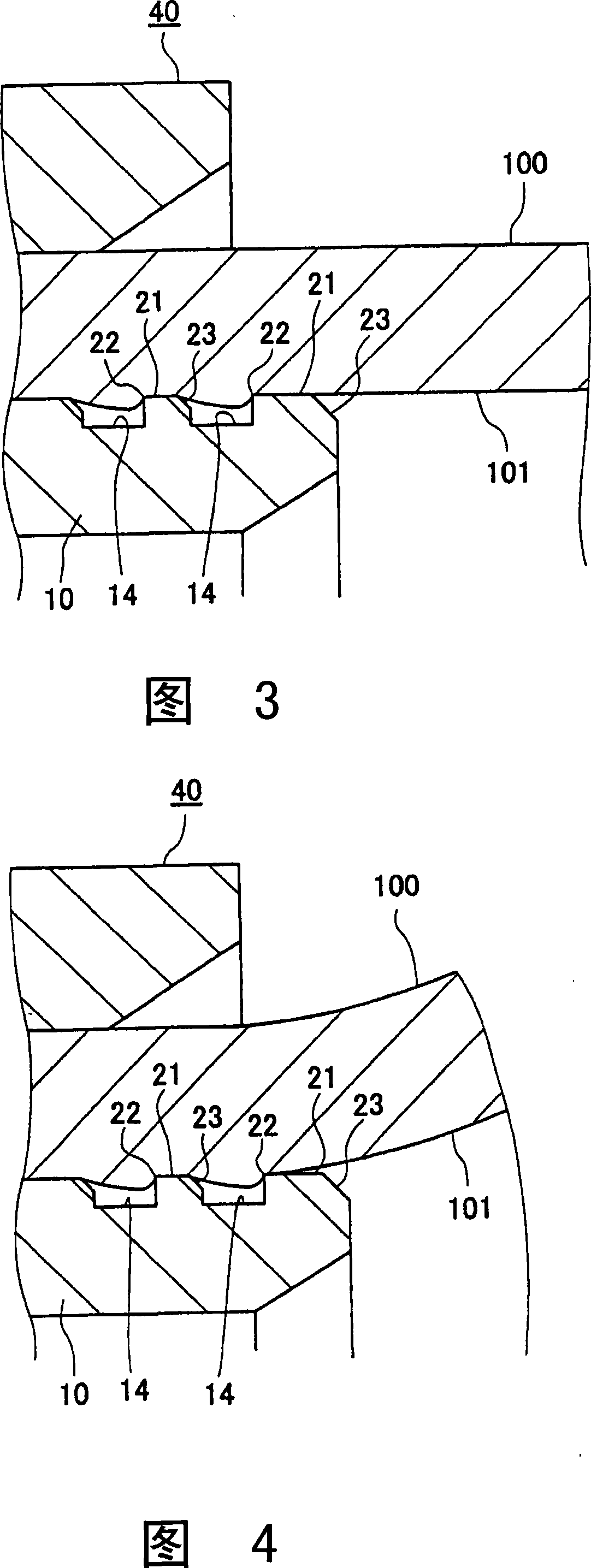

[0039] 1 is a half sectional side view showing a state of use of a joint for resin pipes according to an embodiment of the present invention, and FIG. 2 is a half sectional view showing a state of use of a modified example of the joint for resin pipes.

[0040] In FIG. 1 , a joint for resin pipes (hereinafter referred to as "joint") A is integrally provided with a cylindrical connection cylinder part 10 on a joint body 1 manufactured by cutting, and a resin pipe 100 such as a polyethylene pipe is fitted over the joint body 1. on the connecting cylinder portion 10 . In addition, the resin tube 100 fitted on the connecting cylinder 10 is prevented from coming off at two positions, the central part in the axial direction of the connecting cylinder 10 and the front end thereof, by a locking mechanism 20 which will be described later, and these two positions are assisted. The cylindrical cover 40 of the detent mechanism 20 is fitted on the outside of the resin tube 100, and at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com