Coaxial superimposed multiple layer arbitrary angle rotary caging device

A technology of arbitrary angle and limit device, which is applied in the direction of position/direction control, instrument, control/adjustment system, etc., can solve the problems of inability to realize arbitrary angle control, complex structure of limit device, limited application range, etc., and achieve limit Flexible, simple structure, and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

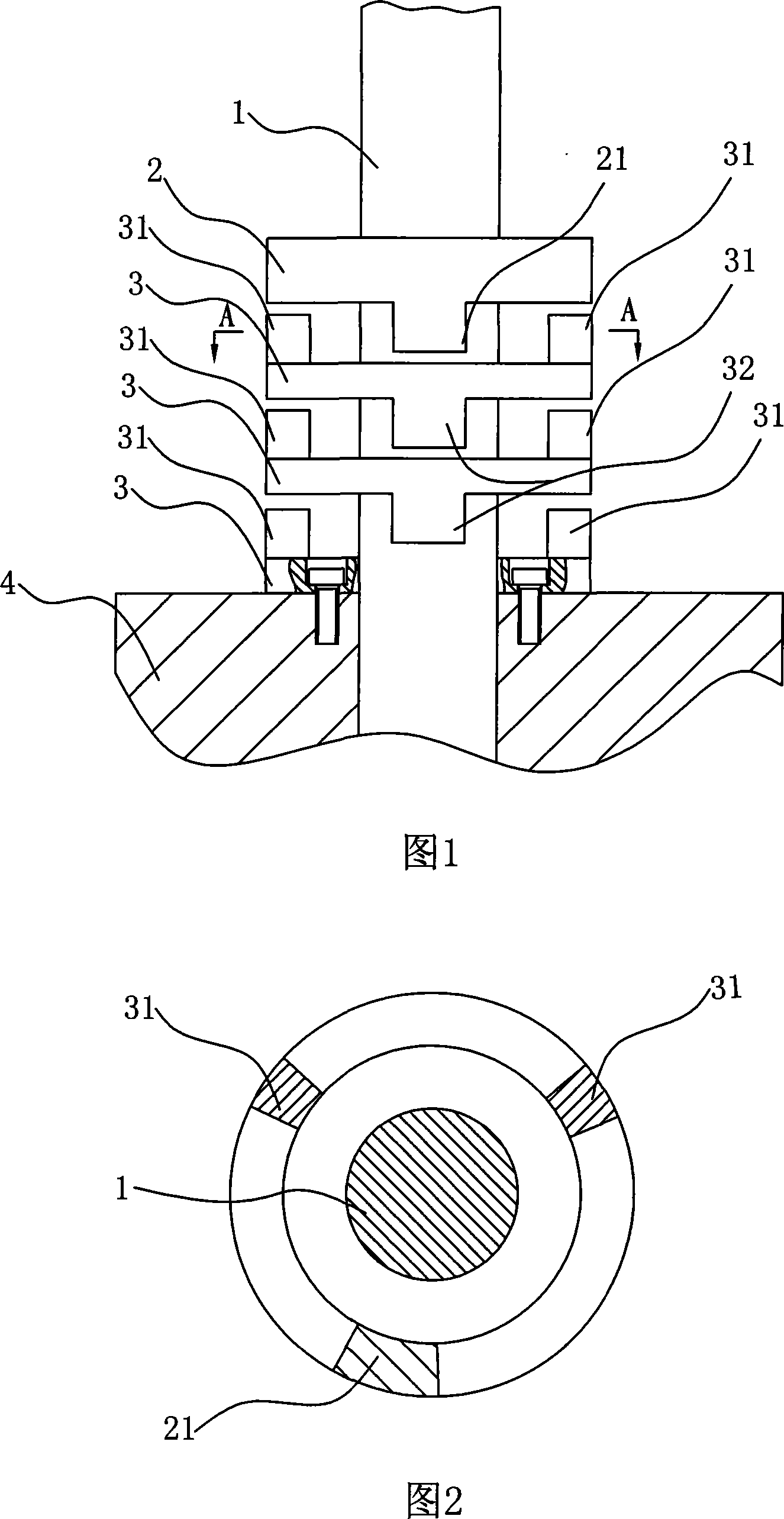

[0013] Embodiment 1: As shown in Figures 1 and 2: a coaxial stacked multi-layer rotation limit device at any angle, which includes a rotary shaft 1, a follow-up dial ring 2, a limit stop ring 3 and a machine base 4; The follow-up dial ring 2, the limit stop ring 3 and the machine base 4 are sequentially installed on the rotary shaft 1, the follow-up dial ring 2 is fixedly connected with the rotary shaft 1, and the limit stop ring 3 and the machine base 4 are set on the rotary shaft 1, the device includes at least one limit stop ring 3, the limit stop ring 3 close to the machine base is fixedly connected with the machine base 4, and the follow-up dial ring 2 is adjacent to the limit stop ring 3 An angular rotation limiting device is arranged between the limit stop ring 3; an axially protruding toggle foot 21 is arranged on the outer ring of the follow-up dial ring 3; There are two protruding gear feet 31, and the other side of the limit stop ring 3 is correspondingly provided w...

Embodiment 2

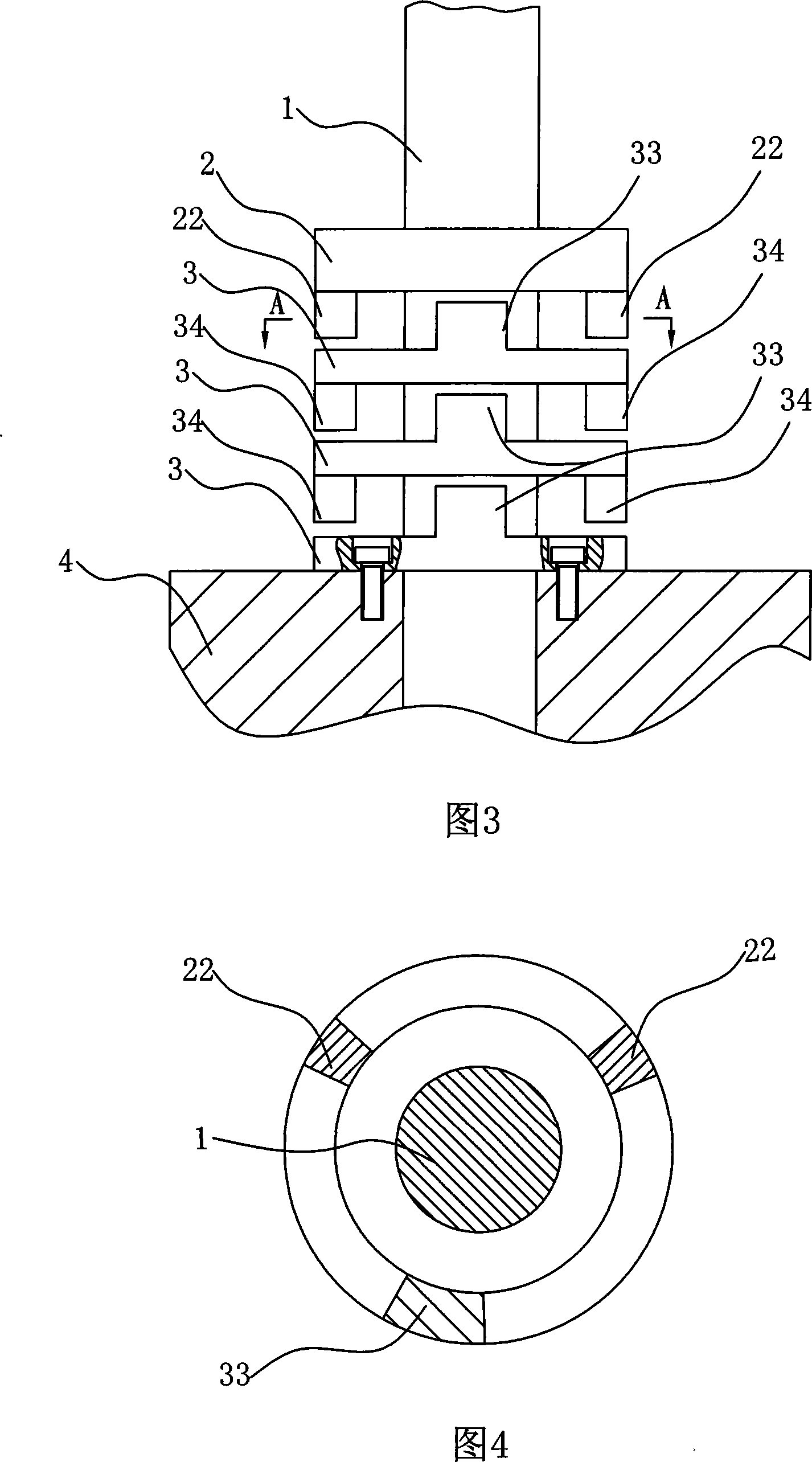

[0014] Embodiment 2: As shown in Figures 3 and 4: a coaxial stacked multi-layer rotation limit device at any angle, which includes a rotary shaft 1, a follower ring 2, a limit stop ring 3 and a machine base 4; The follow-up dial ring 2, the limit stop ring 3 and the machine base 4 are sequentially installed on the rotary shaft 1, the follow-up dial ring 2 is fixedly connected with the rotary shaft 1, and the limit stop ring 3 and the machine base 4 are set on the rotary shaft 1, the device includes at least one limit stop ring 3, the limit stop ring 3 close to the machine base is fixedly connected with the machine base 4, and the follow-up dial ring 2 is adjacent to the limit stop ring 3 The limit stop ring 3 is provided with an angular rotation limit device; the outer ring of the follow-up dial ring 2 is provided with two axially protruding gear feet 22; The protruding toggle pin 33, the other side of the limit stop ring 3 is correspondingly provided with two gear pins 34; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com