Nuclear reactors cooling agent pump mechanical sealing leakage amount abnormity quick processing method

A technology for coolant pumps and mechanical seals, applied in nuclear reactor monitoring, reactors, sealing, etc., can solve problems such as wear and tear of sealing components, and achieve the effects of easy control, normal operation, and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

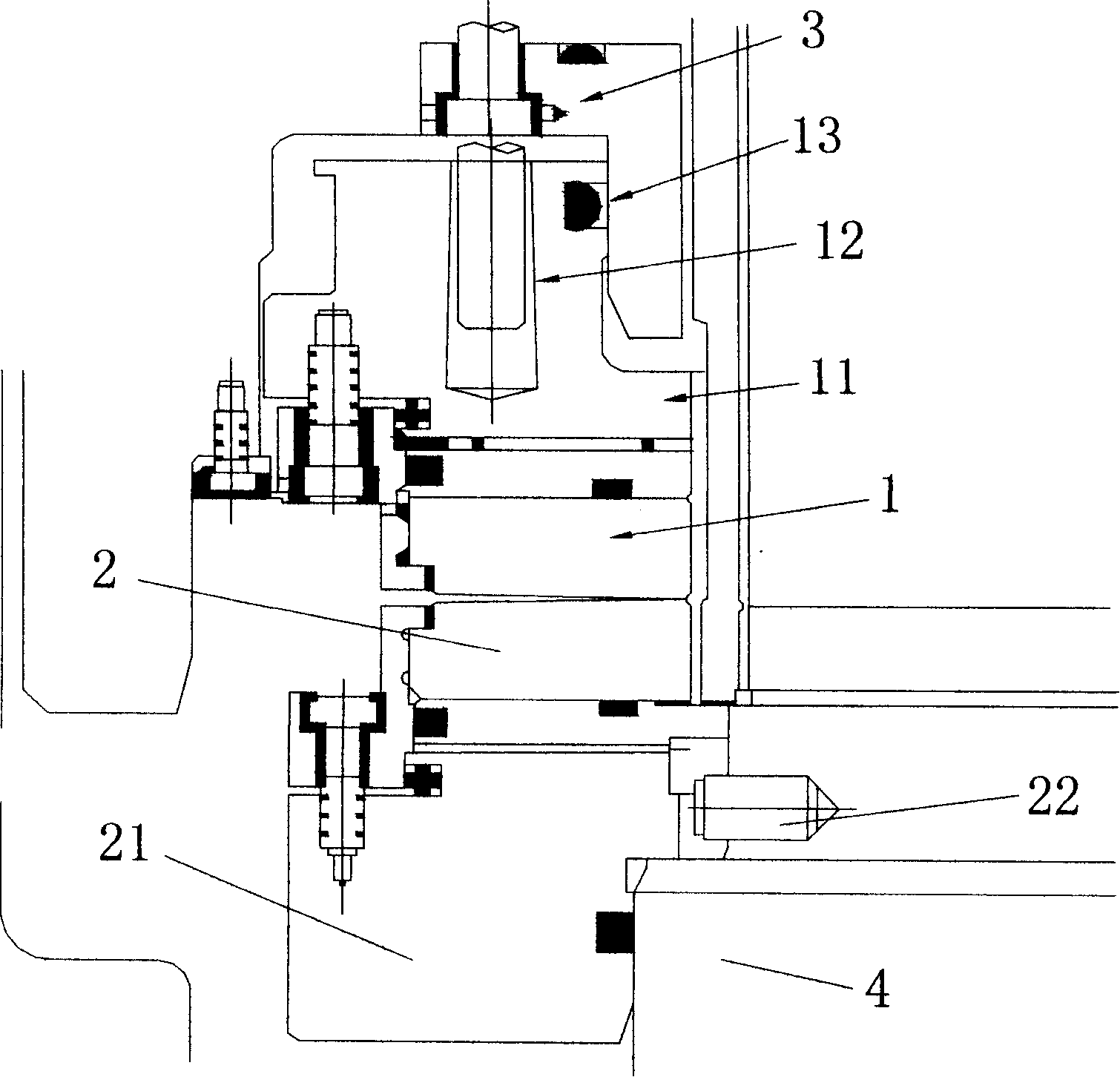

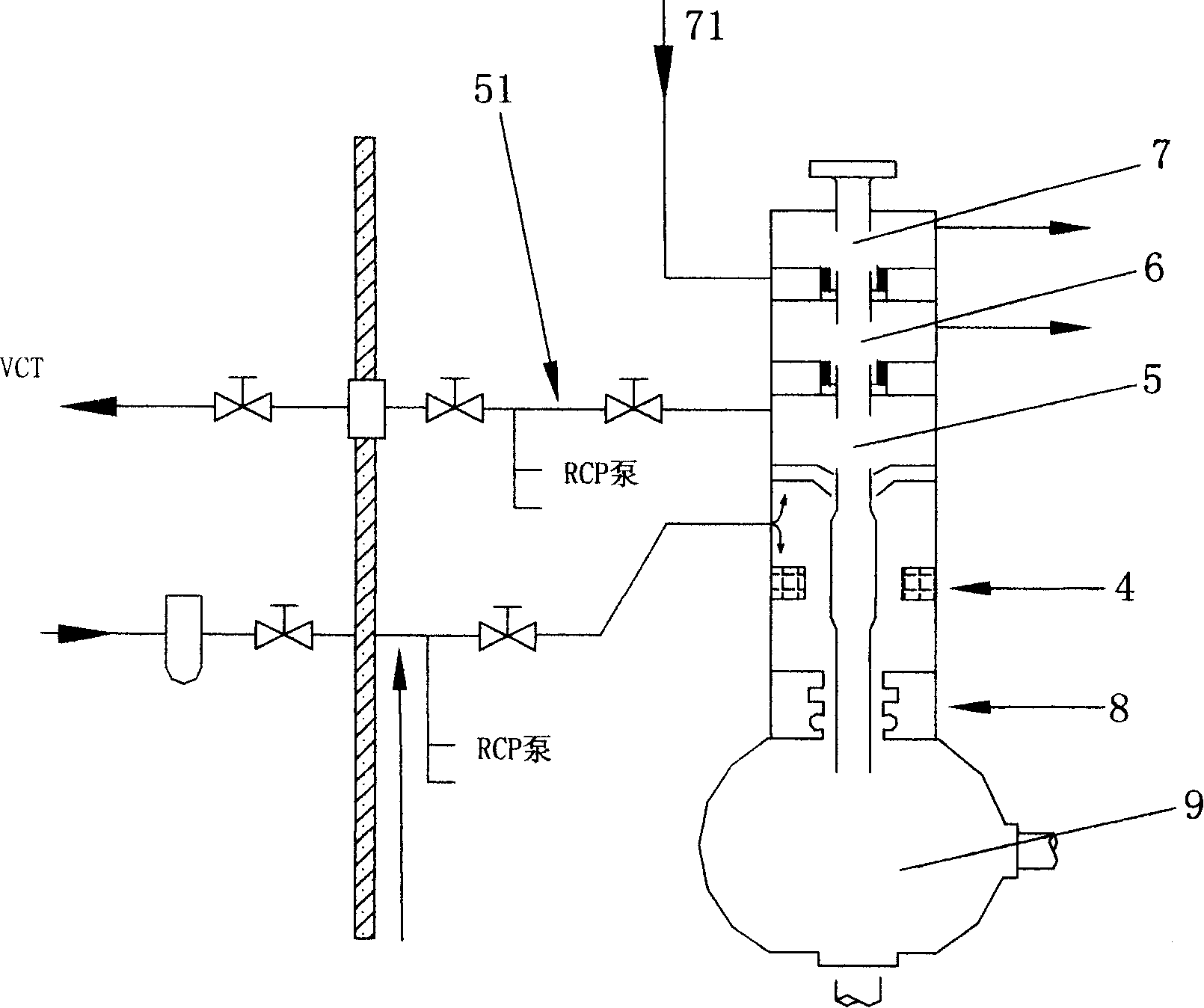

[0041] The nuclear main pump is a single-stage, single-suction, vertical mixed-flow pump driven by a three-phase induction motor. From top to bottom, it consists of motor, sealing assembly and pump hydraulic components. Reactor coolant is pumped by an impeller mounted on the lower end of the shaft. The coolant is sucked through the bottom of the pump casing, flows up through the impeller, and exits through a diffuser (guide vane) and an outlet connection on the side of the casing.

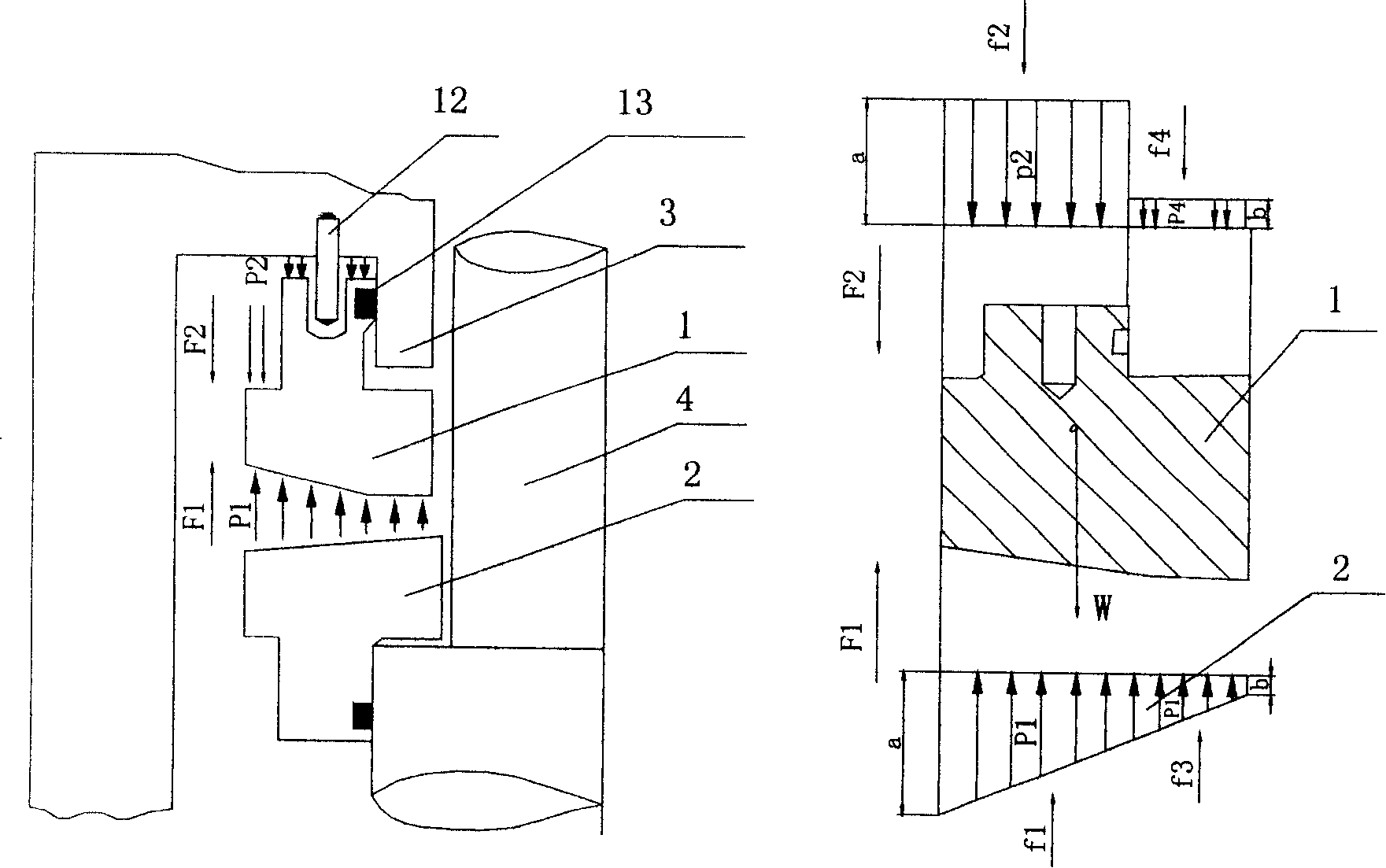

[0042] The shaft seal assembly of the nuclear main pump is composed of three-stage mechanical seals in series, which is one of the most critical components on the main pump. The three-stage shaft seals arranged in series are used to control the upward leakage of the pumped medium along the pump axis. figure 1 Shown is a schematic diagram of the structure of the sealed chamber, such as figure 1 As shown, the No. 1 seal is the main seal in the third-stage seal, which bears almost all the pressure di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com