Method for preparing porous foam nickel-titanium shape memory alloy

A memory alloy and porous foam technology, which is applied in the field of foam metal materials, can solve the problems of difficult pore structure control of products, difficult pore structure control, process stability control, etc., and achieves recyclable materials, uniform and controllable structure, and porous structure. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

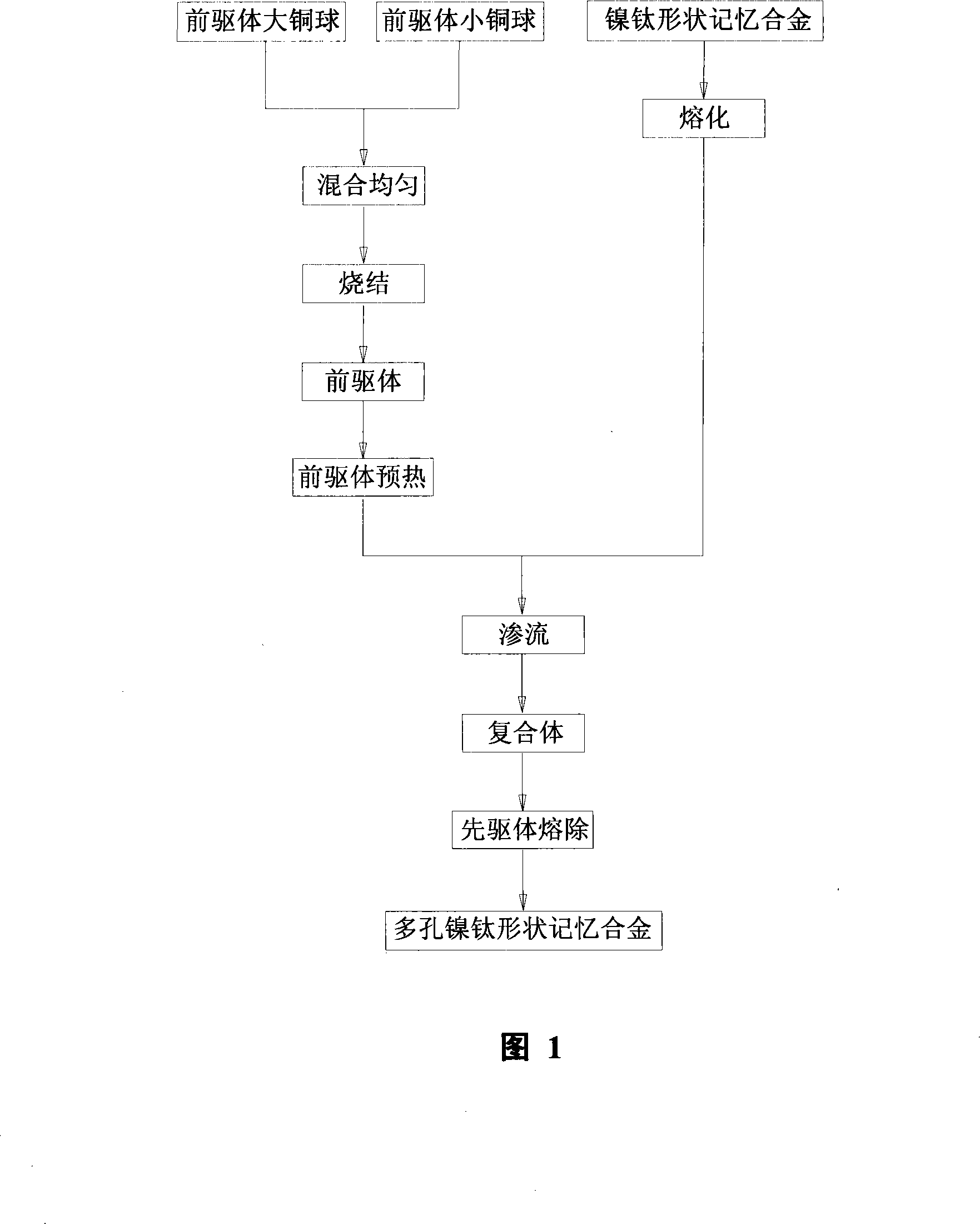

Method used

Image

Examples

Embodiment 1

[0012] Copper balls (big ball diameter 0.5mm, small ball diameter 0.1mm, volume ratio of big and small balls 5:1) were mixed evenly in the mixer (speed: 120rpm, mixing time: 30min.), put into H 2 Sintering is carried out in a silicon carbon rod sintering furnace in a reducing atmosphere (sintering temperature: 960°C, sintering time 25min.) to obtain a copper infiltration precursor, and the sintered copper infiltration precursor is preheated (preheating temperature: 880°C, preheating time 10min.) Standby. At the same time, the nickel-titanium shape memory alloy is heated to 1400°C in a graphite crucible with an induction furnace to melt and hold for 30 minutes. It penetrates into the precursor through pressure seepage (seepage pressure: 26MPa, seepage temperature: 1390°C, seepage velocity: 3mm / s) In the process, the composite body after infiltration was cooled with water to obtain a composite body of nickel-titanium shape memory alloy and copper precursor, and the composite bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com