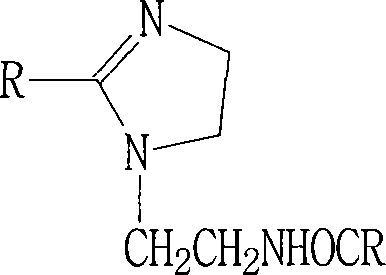

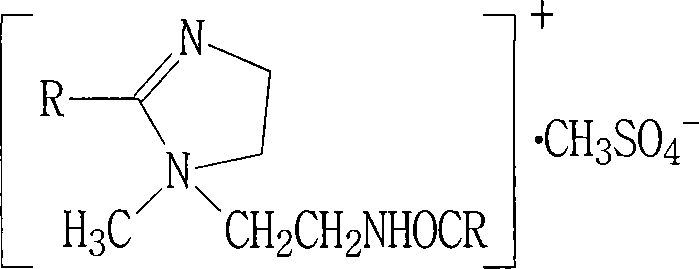

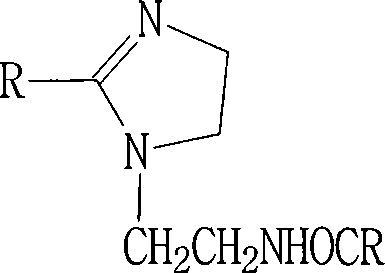

Method for preparing dialkylamidoimidazoline quaternary ammonium salt type paper softening agent

A technology of alkylamide imidazoline and softener, which is applied in the field of preparation of paper softener and bis-alkylamide imidazoline quaternary ammonium salt type paper softener, can solve the problem of lack of hand feeling properties of amide softener and reduce the static friction between fibers Coefficient and other problems, to achieve the effect of reducing the static friction coefficient between fibers and strong adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1, synthesis of two alkylamide imidazolines

[0029] In a 500ml four-neck flask equipped with a stirrer, a thermometer, a condenser and a water separator, add 320 parts of stearic acid and heat to melt, stir and melt completely, add 1.2 parts of sodium methoxide catalyst and nitrogen protection, slowly drop 80 Parts of diethylenetriamine, exothermic phenomenon can be observed after a few minutes, and the color of the reactant gradually changes from light to dark. Control the dropping speed, gradually raise the temperature after the dropping, and gradually separate the water until the temperature rises to 200°C, and stop the reaction when no water comes out.

[0030] Step 2, synthesis of dialkylamide imidazoline quaternary ammonium salt type paper softener

[0031] Take 300 parts of the intermediate dialkylamide imidazoline prepared in the first step and add it to a 500ml three-necked flask, add 125 parts of isopropanol and stir evenly, then raise the temperature t...

Embodiment 2

[0033] Step 1, synthesis of two alkylamide imidazolines

[0034] In a 500ml four-neck flask equipped with a stirrer, a thermometer, a condenser and a water separator, add 340 parts of stearic acid and heat to melt, stir and melt completely, add 1.6 parts of sodium methoxide catalyst and nitrogen protection, slowly drop 100 parts Parts of diethylenetriamine, exothermic phenomenon can be observed after a few minutes, and the color of the reactant gradually changes from light to dark. Control the dropping speed, gradually raise the temperature after the dropping, and gradually separate the water until the temperature rises to 200°C, and stop the reaction when no water comes out.

[0035] Step 2, synthesis of dialkylamide imidazoline quaternary ammonium salt type paper softener

[0036] Take 280 parts of the intermediate dialkylamide imidazoline prepared in the first step and add it to a 500ml three-necked flask, add 120 parts of isopropanol and stir evenly, then raise the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com