Single layer wall polychloroethylene mute drainpipe

A polyvinyl chloride, single-layer wall technology, applied in the field of drainage pipes, can solve the problems of insignificant noise reduction effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The single-layer wall polyvinyl chloride silent drainage pipe of the present invention first prepares raw materials according to the following parts by mass:

[0083] PVC resin 100 parts, CPE 10 parts, ACR 2.0 parts, TY208 4.0 parts, CaSt 2 0.5 parts, HSt 0.8 parts, WAX 0.5 parts, DOP 4.0 parts, TiO 2 4.0 parts, BaSO 4 150 servings.

[0084] 1. Equipment

[0085] High Speed Kneader, GRH-300R

[0086] Cold mixer, LH-500B

[0087] Conical twin-screw extruder, manufactured by Guangdong Weilijian Machinery Co., Ltd., screw diameter φ60

[0088] extrusion die

[0089] Extrusion follow-up equipment (cooling vacuum setting device, traction device, inkjet printer, cutting machine)

[0090] 2. The operation process is shown in Figure 5

[0091] (1) Prepare the ingredients according to the formula in Table 3,

[0092] (2) Put each batch of materials into the high-speed kneading pot in batches, stir at high speed, the materials rub against each other and heat up, the...

Embodiment 2

[0124] The single-wall polyvinyl chloride silent drainage pipe of the present invention has 200 parts of BaSO4 in the raw material of the pipe. All the other are identical with embodiment 1.

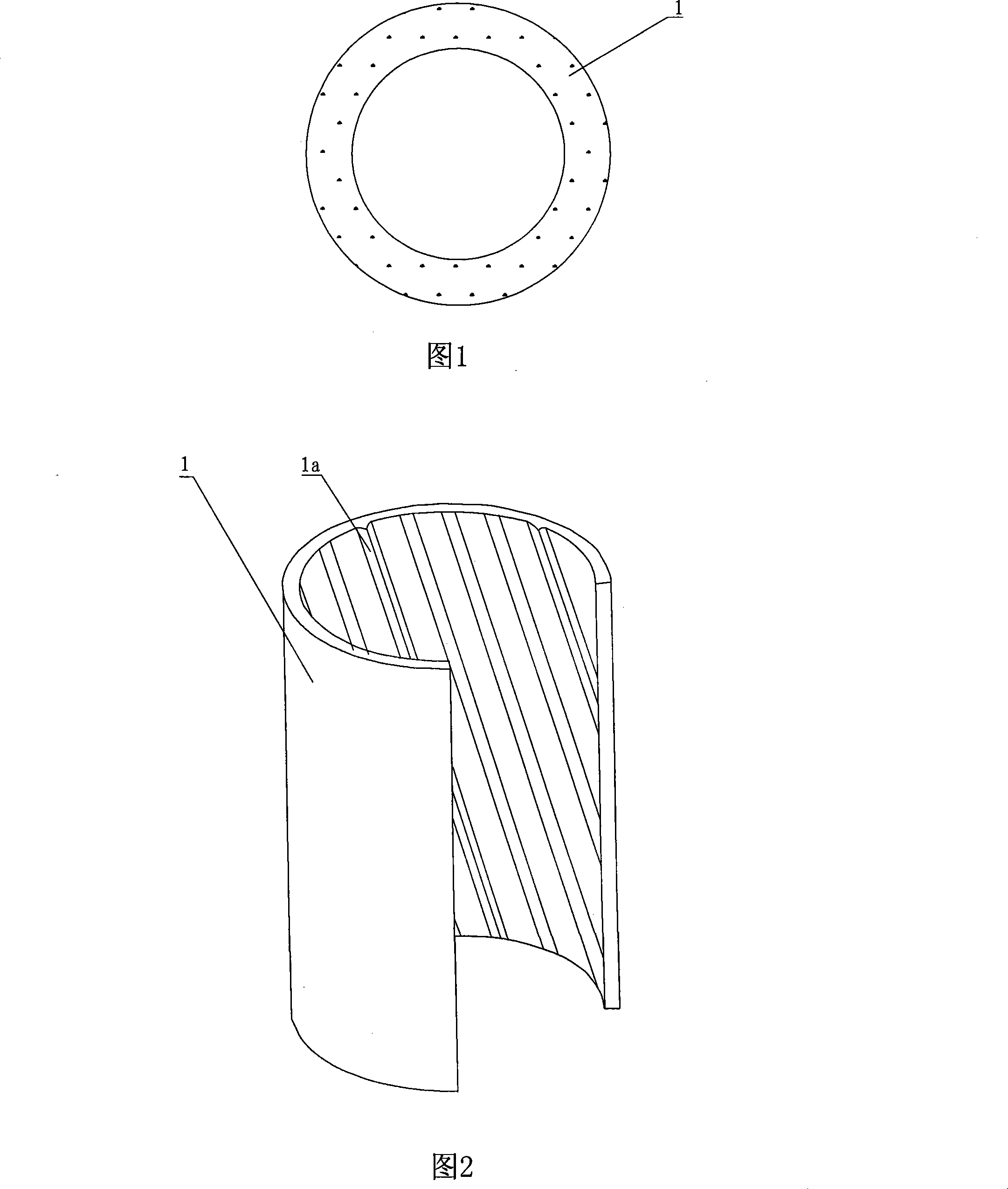

[0125] As shown in Figure 1, a single-wall polyvinyl chloride silent drainage pipe 1 is obtained, and the pipe wall is a single layer;

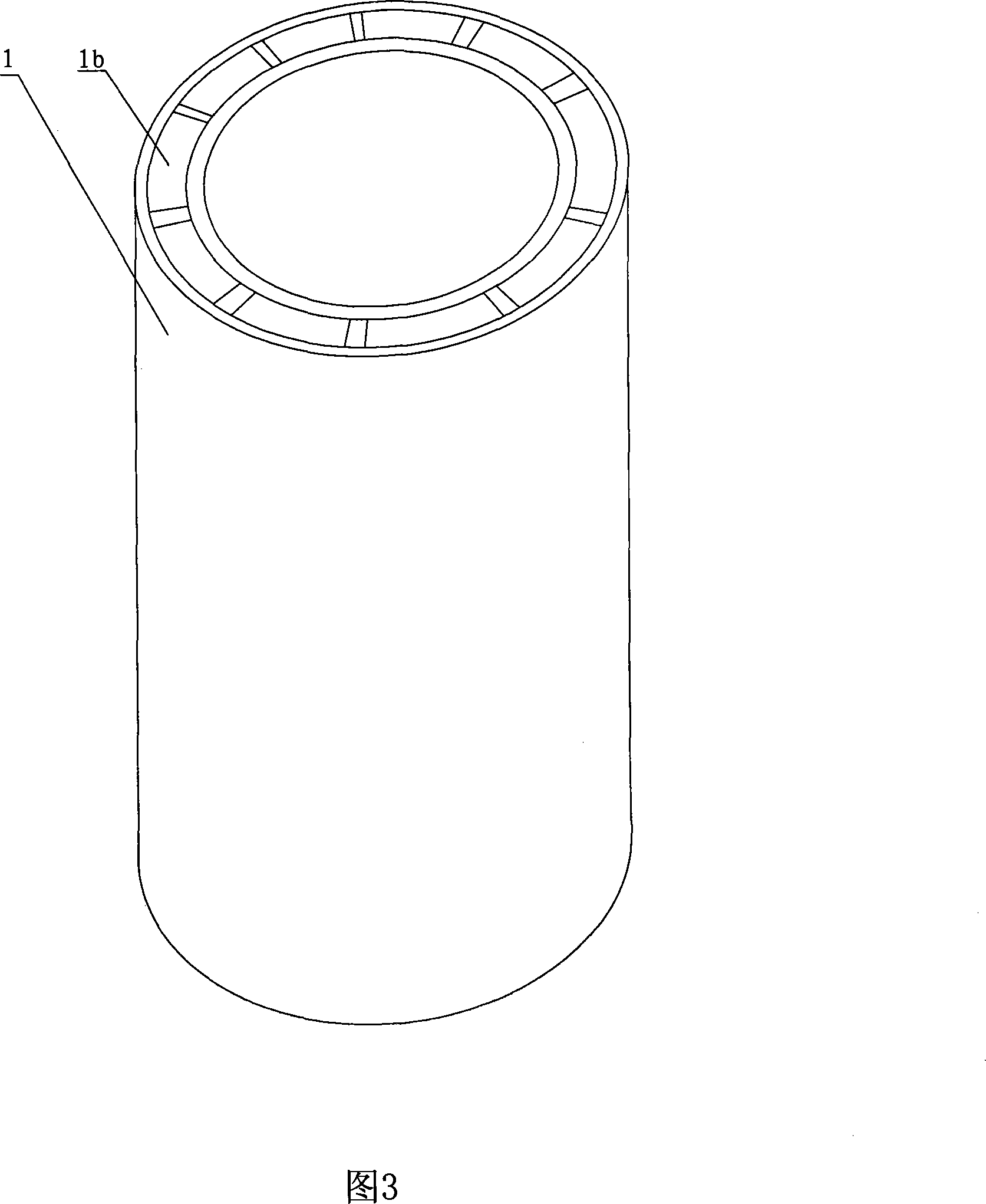

[0126] As shown in Figure 2, the single-layer wall polyvinyl chloride silent drainage pipe 1 with internal spiral ribs 1a on the inner wall is called a single-layer internal spiral polyvinyl chloride silent drainage pipe;

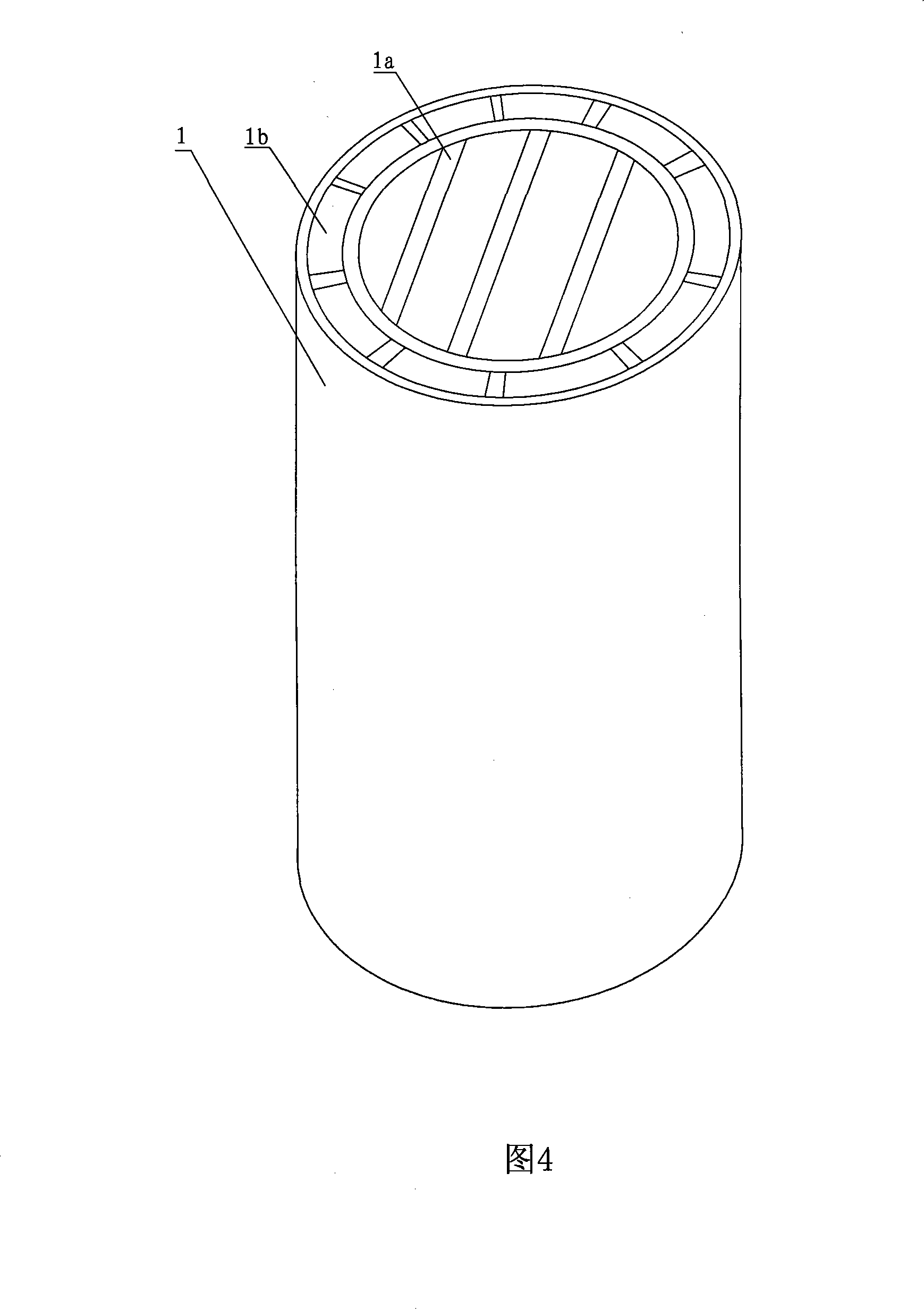

[0127] As shown in Figure 3, the single-layer PVC silent drainage pipe 1 with an axial cavity 1b in the pipe wall is called a single-layer hollow PVC silent drainage pipe;

[0128] As shown in Figure 4, the inner wall is provided with inner spiral ribs 1a, and the single-layer wall PVC silent drainage pipe 1 with an axial cavity 1b in the pipe wall is called a single-wall hollow inner spiral PVC pipe. Vinyl silent drain.

Embodiment 3

[0130] The single-wall polyvinyl chloride mute drainage pipe of the present invention has 250 parts of BaSO4 in the raw material of the pipe. All the other are identical with embodiment 1.

[0131] As shown in Figure 1, a single-wall polyvinyl chloride silent drainage pipe 1 is obtained, and the pipe wall is a single layer;

[0132] As shown in Figure 2, the single-layer wall polyvinyl chloride silent drainage pipe 1 with inner spiral ribs 1a on the inner wall is called a single-layer inner spiral polyvinyl chloride silent drainage pipe;

[0133] As shown in Figure 3, the single-layer PVC silent drainage pipe 1 with an axial cavity 1b in the pipe wall is called a single-layer hollow PVC silent drainage pipe;

[0134] As shown in Figure 4, the inner wall is provided with inner spiral ribs 1a, and the single-layer wall PVC silent drainage pipe 1 with an axial cavity 1b in the pipe wall is called a single-wall hollow inner spiral PVC pipe. Vinyl silent drain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com