Double pressure dry-extinguishing coke waste heat boiler

A waste heat boiler and dry quenching technology, applied in the field of waste heat boilers, can solve the problems of low thermal efficiency and occupation of land resources, and achieve the effect of alleviating land tension and saving electric energy and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

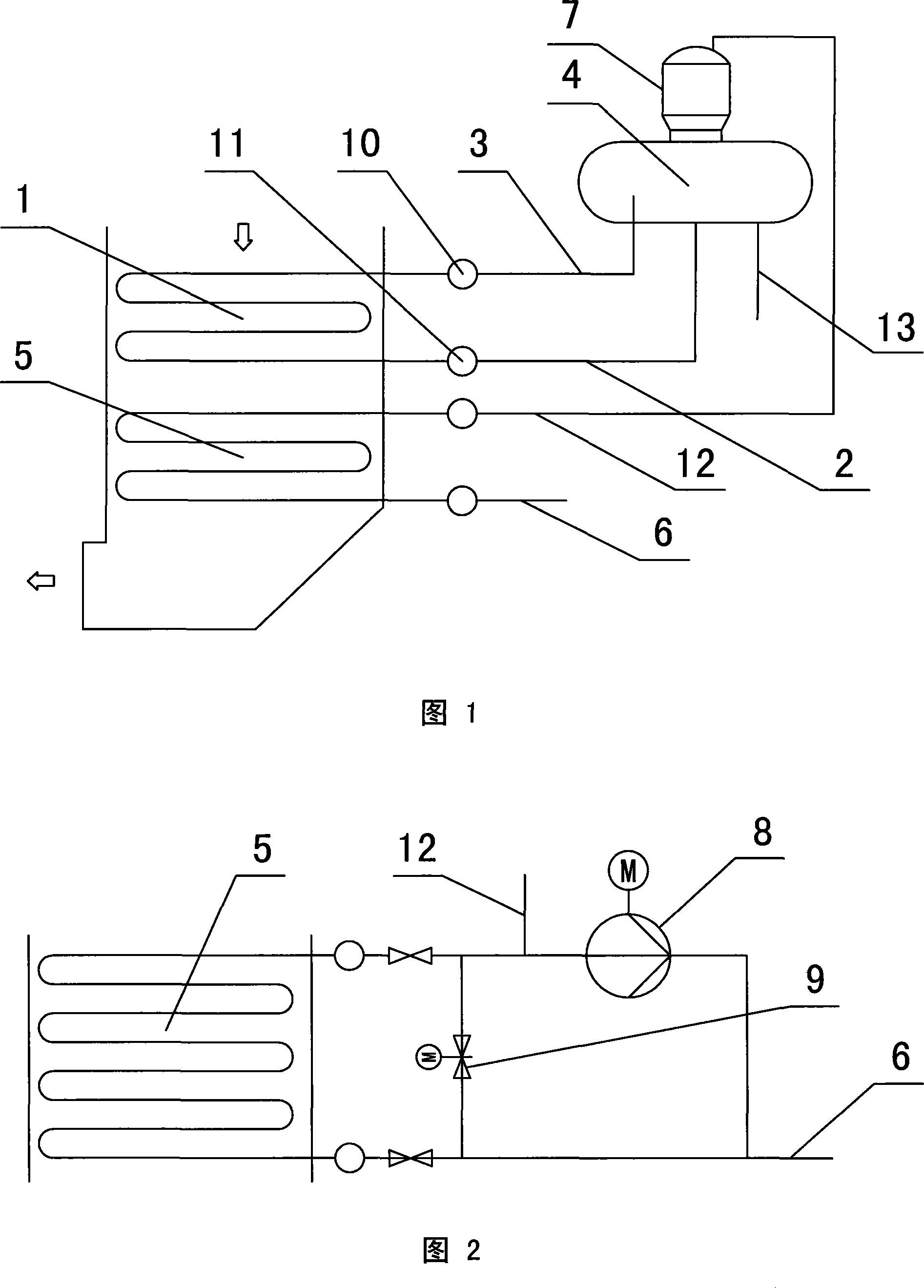

[0014] The dual-pressure CDQ waste heat boiler adopts the natural circulation method and is divided into a high-pressure part and a low-pressure self-deoxygenating part.

[0015] In the high-pressure part, the main pressure parts of the boiler body except the high-pressure economizer adopt a suspension structure, which expands downward as a whole; the high-pressure economizer adopts a supporting structure, which expands upward.

[0016] As shown in Figure 1, the low-pressure self-deoxygenating part of the dual-pressure CDQ waste heat boiler is equipped with a low-pressure evaporator 1, which is a low-pressure finned tube evaporator, and the inlet of the low-pressure evaporator 1 passes through the downtube of the low-pressure evaporator 2 is connected to the low-pressure drum 4. A low-pressure evaporator inlet header 10 is provided between the low-pressure evaporator 1 and the downcomer 2 of the low-pressure evaporator. The outlet of the low-pressure evaporator 1 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com