Vacuum box heat collection water storage integral solar water heater device

A solar water heater and vacuum heat collection technology, applied in the field of solar energy applications, can solve problems such as roofs, long pipelines, difficult maintenance, etc., and achieve the effects of flexible placement, reduction of environmental pollution, and installation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

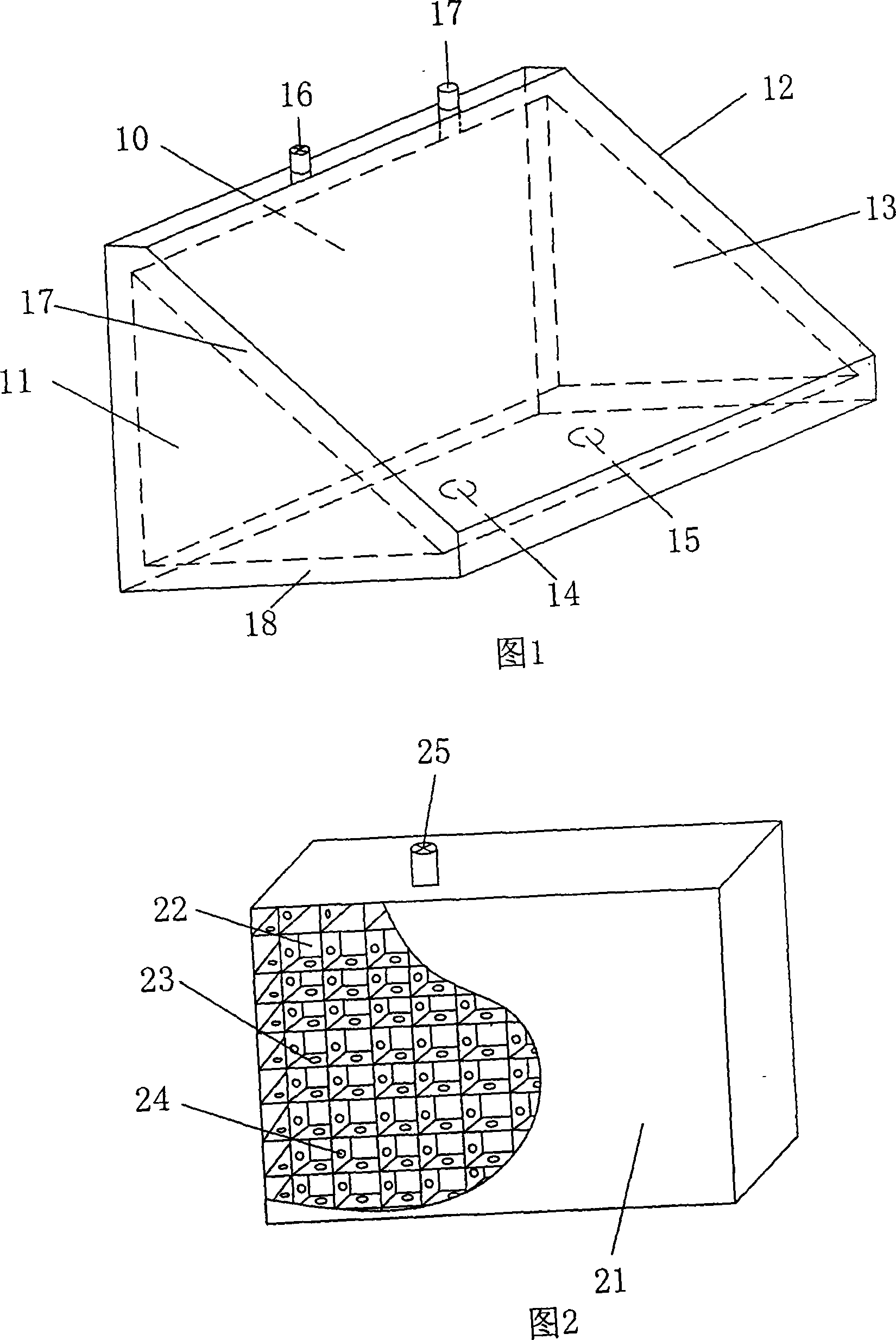

[0026] The structure of Embodiment 1 is shown in Figure 1. The device is a box body with two layers of box walls whose longitudinal section is a right angled triangle. The inner box walls form a water storage cavity 10. It is a right triangle, and the end face of the box body that can be exposed to sunlight includes a front panel 13 and two end panels; Three interconnected vacuum heat collecting layers 17 are formed among them. The outer wall panels of each vacuum heat collecting layer are transparent plates, and the outer surface of the corresponding inner box wall panels is coated with a gradient aluminum nitrogen aluminum film; other inner and outer boxes The walls are filled with insulating material to form an insulating layer 18; the lower end surface of the device is provided with a hot water outlet pipe interface 14 and a cold water inlet pipe interface 15 that are directly connected to the water storage cavity; Vacuum layer and the vacuumized valve 16 and explosion-pro...

Embodiment 2

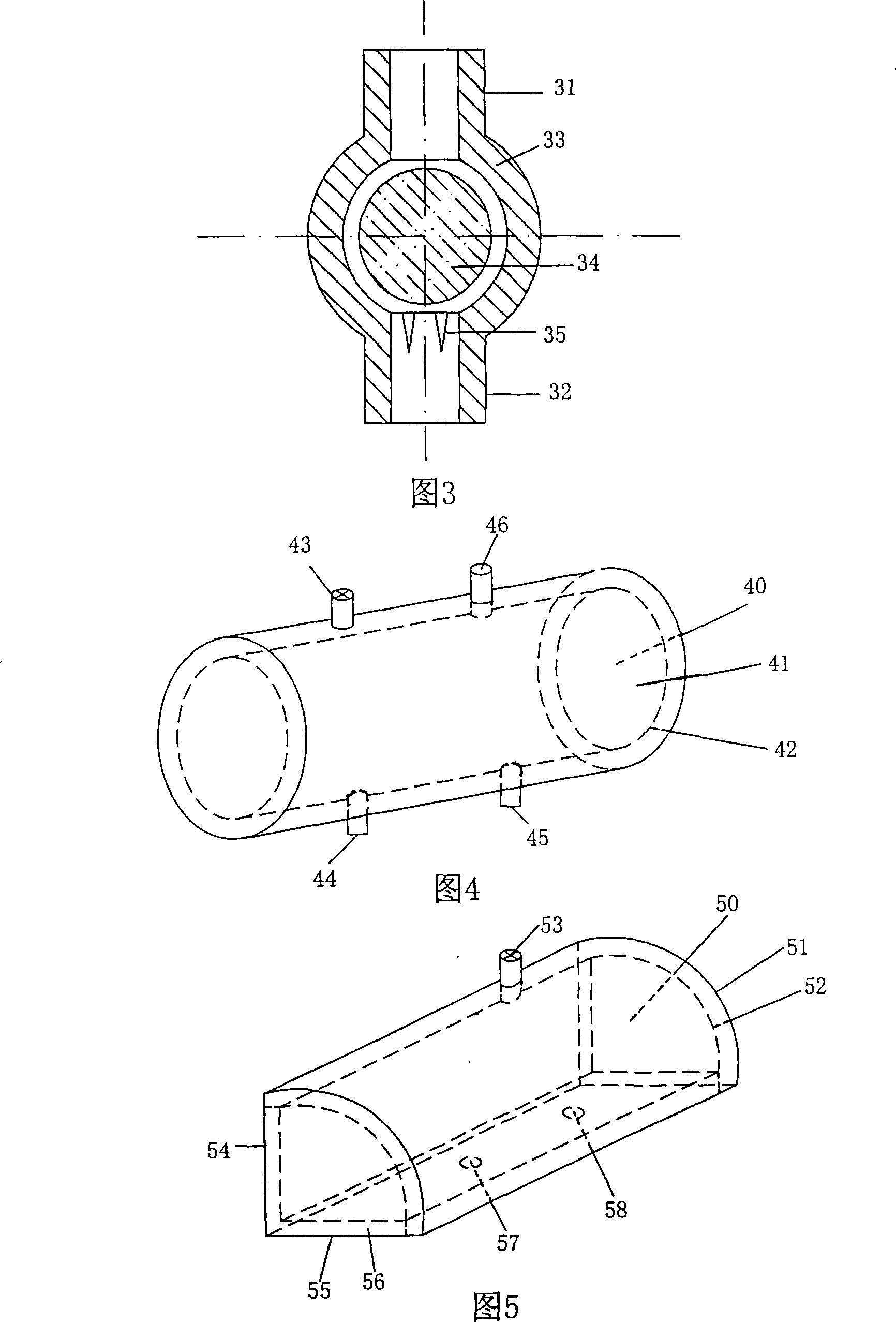

[0030] The structure of Embodiment 2 is shown in Figure 4. The device is a barrel-shaped body with two walls with a circular longitudinal section. The inner barrel forms a water storage cavity 40, and the outer wall of the inner barrel is coated with a gradient aluminum nitrogen aluminum film. , the outer barrel wall is a transparent material, and a vacuum heat-collecting layer is formed between the inner barrel and the outer barrel, and the inner and outer barrel walls 41, 42 are connected with an annular grid rib, and the grid rib is provided with a through hole (not shown in the figure). shown), the gap between the two layers of box walls is connected, and a vacuum valve 43 is set on the upper end of the outer barrel wall of the vacuum heat collecting layer, and the space between the two layers of box walls is The air is drawn out to form a vacuum heat-collecting layer; a hot water outlet pipe interface 44 and a cold water inlet pipe interface 45 that are directly connected ...

Embodiment 3

[0032] The structure of Embodiment 3 is shown in Figure 5. The device is a box body with two layers of walls combined with a flat plate and an arc-shaped plate. Its longitudinal section is a D-like figure surrounded by two vertical lines and a section of arc. , the inner box constitutes a water storage cavity 50, the surface of the outer wall of the arc plate of the inner box is coated with a gradient aluminum nitrogen aluminum film, the arc plate and the two ends of the outer box are made of transparent materials, the arc part and the inner plate at both ends The vacuum heat collecting layer is formed between the outer plate and the inner and outer walls 51 and 52 of the arc are connected by arc-shaped ribs, and the inner and outer walls of the two end faces are connected by horizontal and vertical intersecting grid ribs. A through hole (not shown in the figure) is provided on the sheet, so that the gap between the two layers of box walls can be penetrated, and a vacuum valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com