An online oxidation boron coating cleaning, drying and beading machine

A technology of bead ironing machine and boron coating, which can be used in electrical components and other directions to solve problems such as contact resistance changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

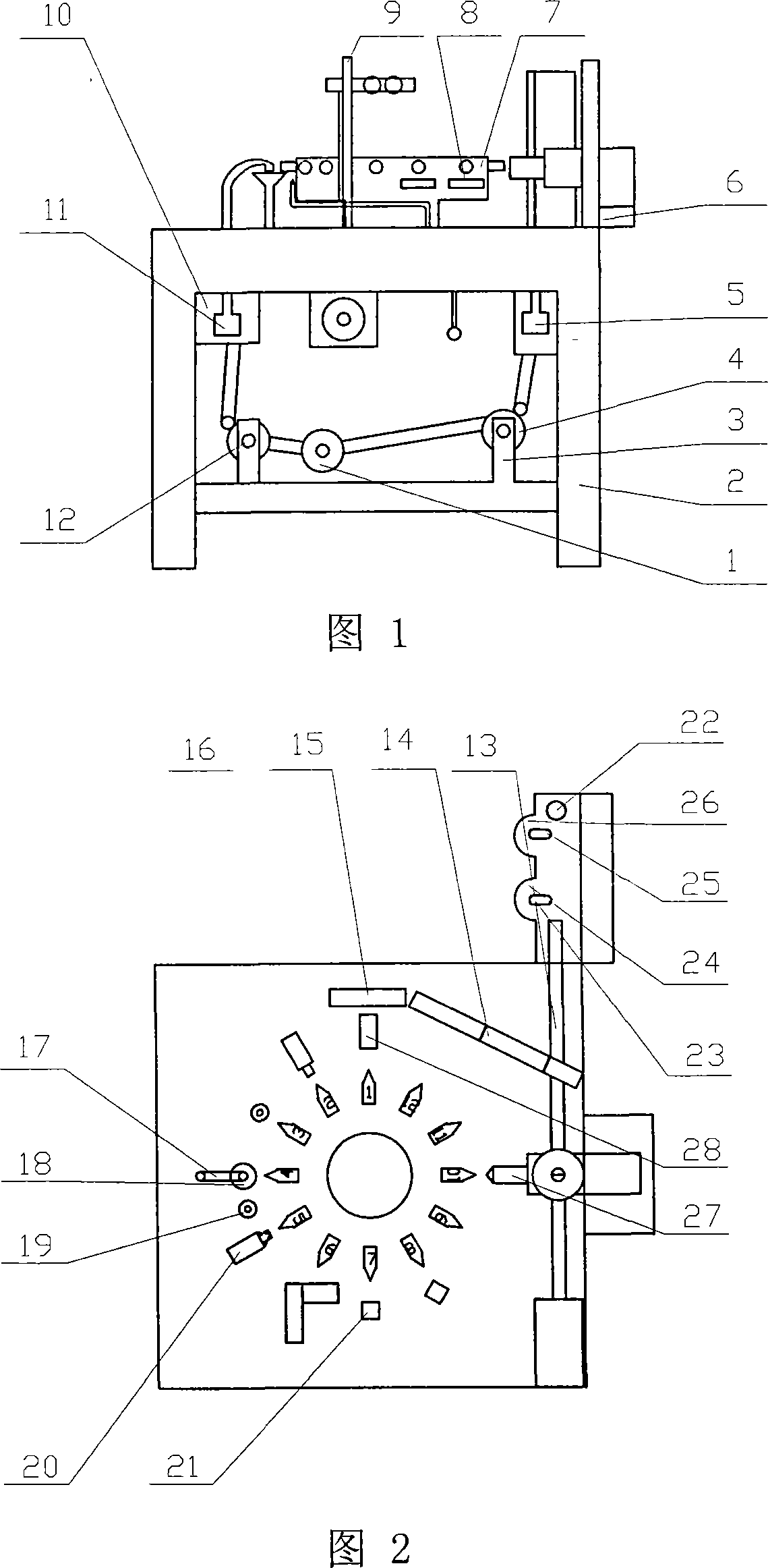

[0010] Content of the present invention will be further described in conjunction with the following examples, but content of the present invention is not limited to content involved in the examples:

[0011] Put the process turntable with guide wires in 14. The process turntable with guide wires in the storage rack and at the same time put the process turntable without silk beads on the stacking frame of 6 process turntables, start 1, and the motor makes 12 15. Driven by the left motion cam support, 15. Under the step-by-step push action of the rotary plate flat feeding mechanism in the guide wire process, the poles are transferred from the guide wire process to the station 1, and the guide wire is formed by 28. The magnetic adsorption guide wire feeding device 8. Put the jaws of the pliers on the rotary clamp into the station 1, and clamp them with a flat head. The motor rotates to drive the 7. The center turntable is transferred to the lower station 2. 12. The cam on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com