A piezoelectric ceramic fiber with metal cores

A technology of piezoelectric ceramics and metal cores, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc. Problems such as poor bonding with piezoelectric ceramic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

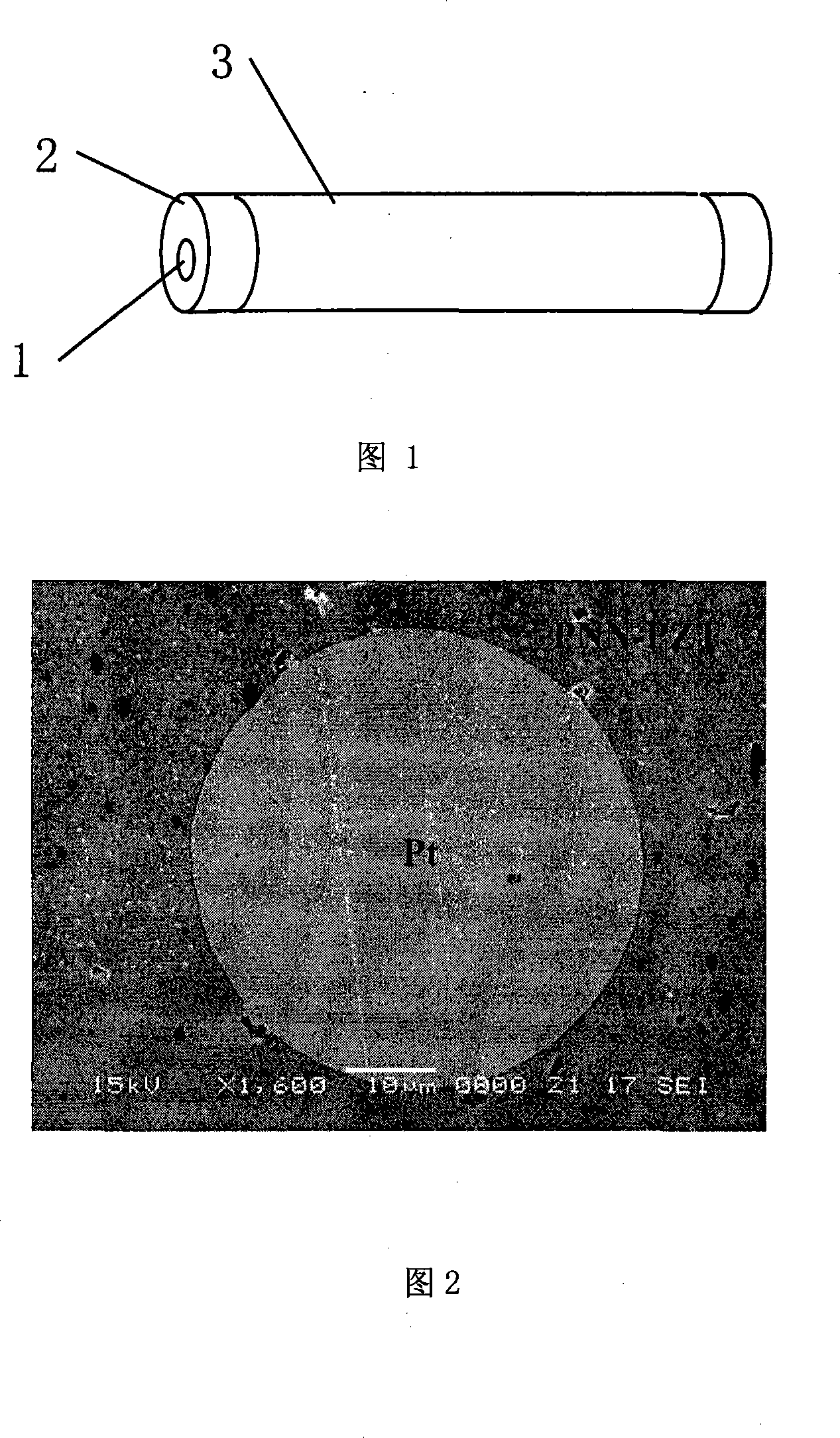

[0023] As shown in Figure 1, the piezoelectric ceramic fiber containing a metal core in this embodiment includes a metal core 1, a piezoelectric ceramic material 2 covering the metal core 1, and a coating electrode 3 coated on the outer surface of the piezoelectric ceramic material 2 The cross-section of the metal core 1 is circular, and its diameter is 10 microns. The metal core 1 is made of a metal material with a high temperature resistance of 1000°C-3500°C and is not easily oxidized, such as platinum, or other high temperature resistant and not easily oxidized. made of metal materials such as gold or molybdenum or tungsten; the piezoelectric ceramic material 2 is a perovskite structure piezoelectric ceramic material, and the molecular formula of the perovskite structure piezoelectric ceramic material is Pb(Zr 0.35 Ti 0.65 )O 3 ;

Embodiment 2

[0025]As shown in Figure 1, the piezoelectric ceramic fiber containing a metal core in this embodiment includes a metal core 1, a piezoelectric ceramic material 2 covering the metal core 1, and a coating electrode 3 coated on the outer surface of the piezoelectric ceramic material 2 The cross-section of the metal core 1 is circular, and its diameter is 200 microns. The metal core 1 is made of a metal material that is resistant to high temperatures of 1000°C-3500°C and is not easily oxidized, such as gold, or other high temperature resistant and not easily oxidized. made of metal materials such as platinum or molybdenum or tungsten; the piezoelectric ceramic material 2 is a piezoelectric ceramic material with a perovskite structure, and the molecular formula of the piezoelectric ceramic material with a perovskite structure is Pb(Zr 0.65 Ti 0.35 )O 3 ;

Embodiment 3

[0027] As shown in Figure 1, the piezoelectric ceramic fiber containing a metal core in this embodiment includes a metal core 1, a piezoelectric ceramic material 2 covering the metal core 1, and a coating electrode 3 coated on the outer surface of the piezoelectric ceramic material 2 The cross-section of the metal core 1 is circular, and its diameter is 100 microns. The metal core 1 is made of a high temperature resistant 1000°C-3500°C and non-oxidizable metal material such as molybdenum, or other high temperature resistant and non-oxidizable metal materials. Metal materials such as platinum or gold or tungsten, etc.; piezoelectric ceramic material 2 is a piezoelectric ceramic material with a perovskite structure, and the molecular formula of the piezoelectric ceramic material with a perovskite structure is Pb(Zr 0.5 Ti 0.5 )O 3 ;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com