Connecting device between batteries

A connection device and battery technology, which is applied in the direction of conductive connection, nickel storage battery, secondary battery, etc., can solve the problems of reduced welding strength, increased resistance, deformation of battery shell and sealing plate, etc., and achieves the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

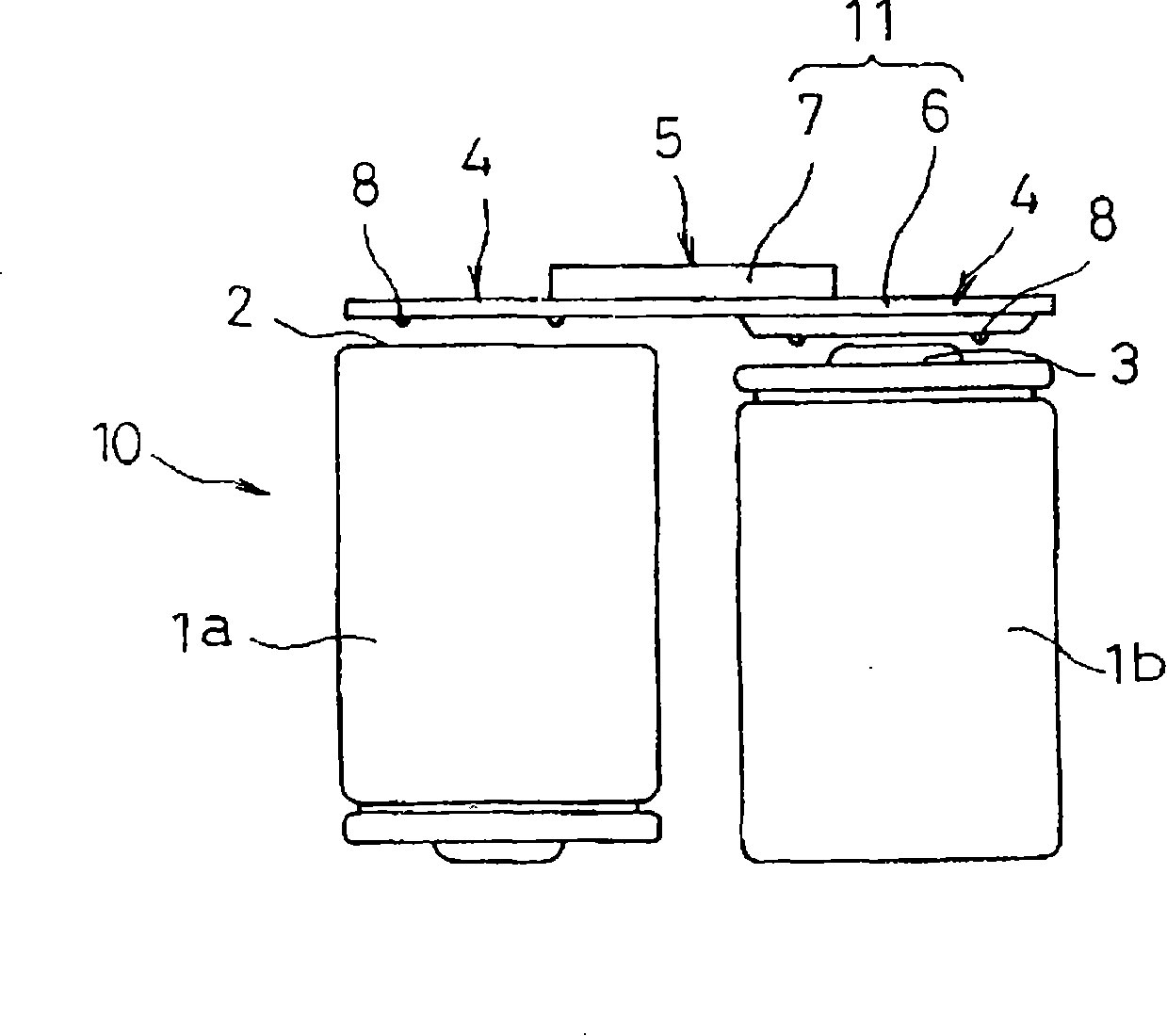

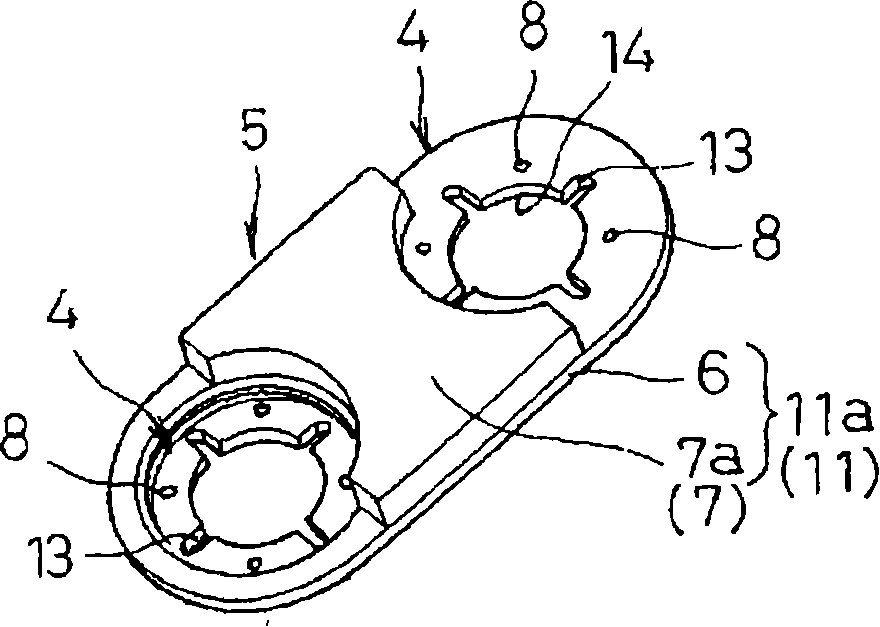

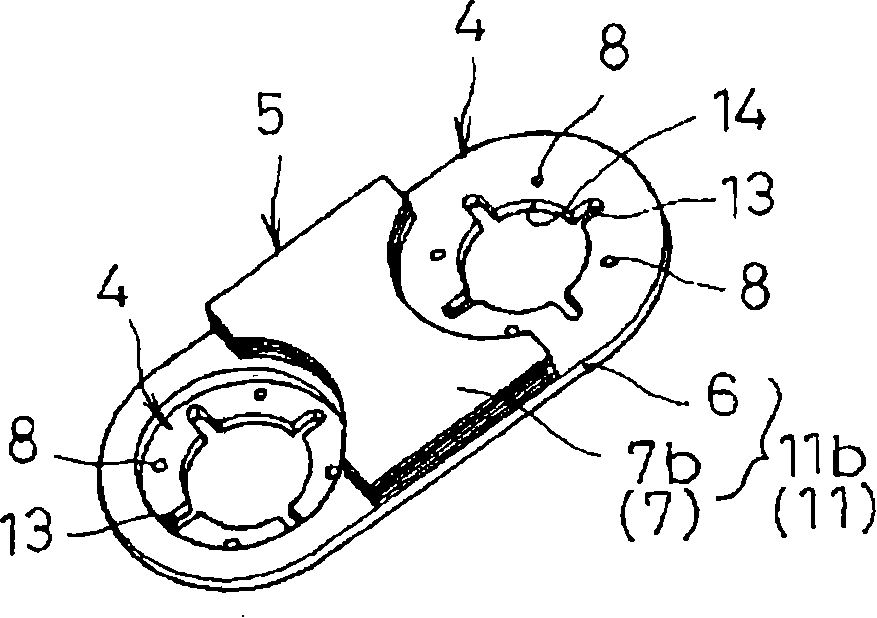

[0035] First, refer to Figure 1 to Figure 5 The first embodiment will be described. figure 1 It is a front view showing the connection process of the battery pack. The battery assembly 10 includes: two batteries 1a, 1b; an inter-battery connection plate 11, used as an inter-battery connection device, to connect terminals of different polarities of these batteries 1a, 1b, specifically to connect the bottom surface 2 of the battery case and the battery. between the sealing plates 3. The inter-battery connecting plate 11 is composed of welded portions 4 and 4 at both ends and an intermediate portion 5 between the welded portions 4 and 4 connecting the two ends, and the intermediate portion 5 is thicker than the welded portion 4 . exist figure 1 In the example shown in FIG.

[0036] Protruding parts 8 protrude from the welding parts 4 at both ends, and the welding parts 4 at both ends are respectively resistance-welded with the bottom surface 2 of the battery case and the s...

no. 2 Embodiment approach

[0047] Next, refer to Figure 6A ~ Figure 10 A second embodiment of the present invention will be described. In the above-mentioned first embodiment, an example was shown in which the inter-battery connection device is constituted by the inter-battery connection plate 11 which is a single component, but in this embodiment, two components, the connection plate 16 and the connection ring 18 are joined to form the structure. In addition, in the description of this embodiment, the same reference numerals are attached to the same components as those of the above-mentioned first embodiment, and description thereof will be omitted.

[0048] Such as Figure 6A ~ Figure 6C As shown, the inter-battery connecting device of the present embodiment includes: a connecting plate 16 having at one end a thinner welding portion 4 opposite to the sealing plate 3 of the battery 1b, and a thicker middle portion 5, It also has a connection piece 17 protruding from the middle part 5 to the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com