Continuous operation method for desulfurization absorption column and temporary bleeder for flue gas

A desulfurization absorption tower, flue gas discharge technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problem that the flue gas desulfurization system cannot run continuously, achieve compact structure, recover economic losses, and easily disassemble The effect of pretending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

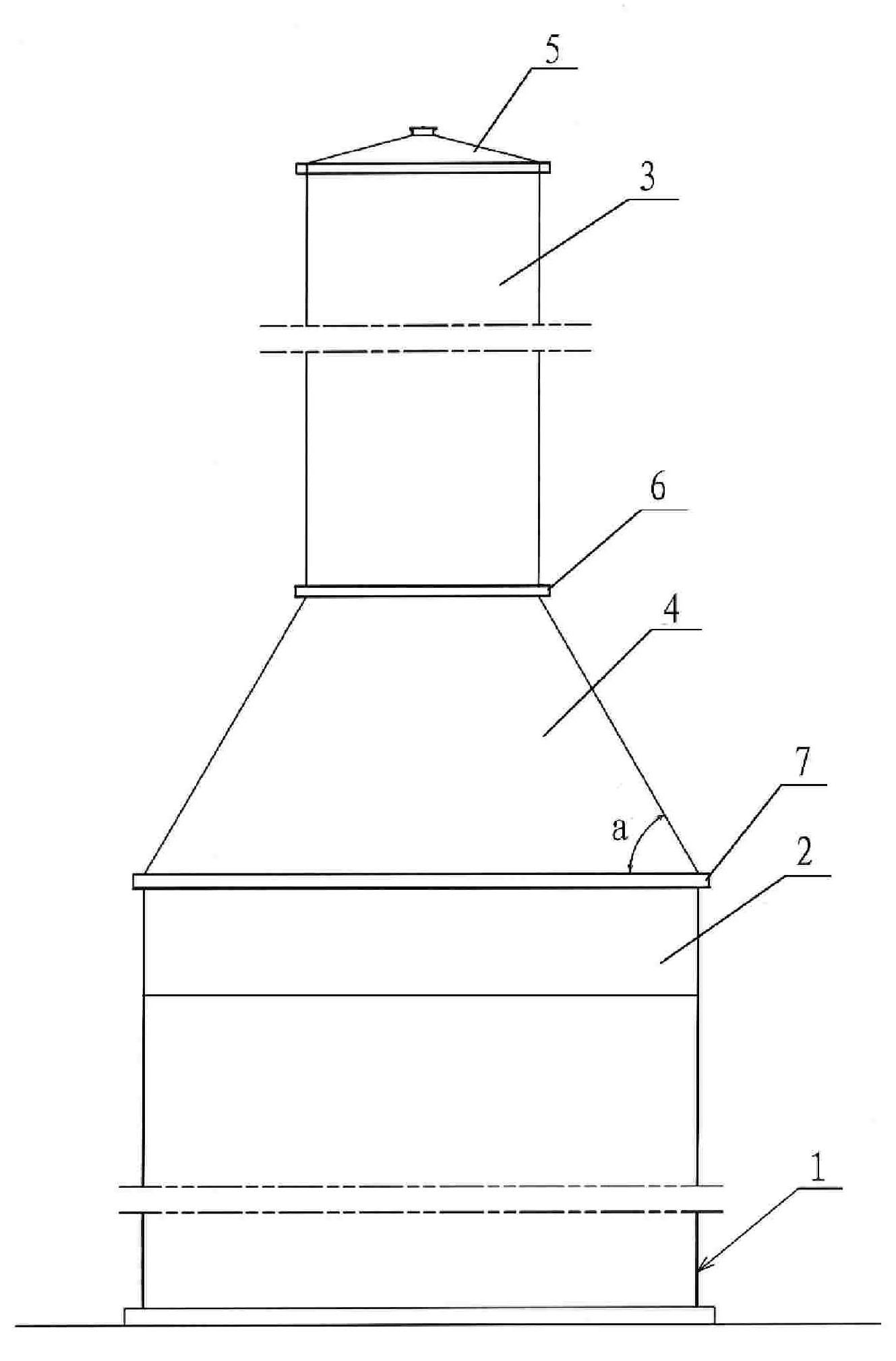

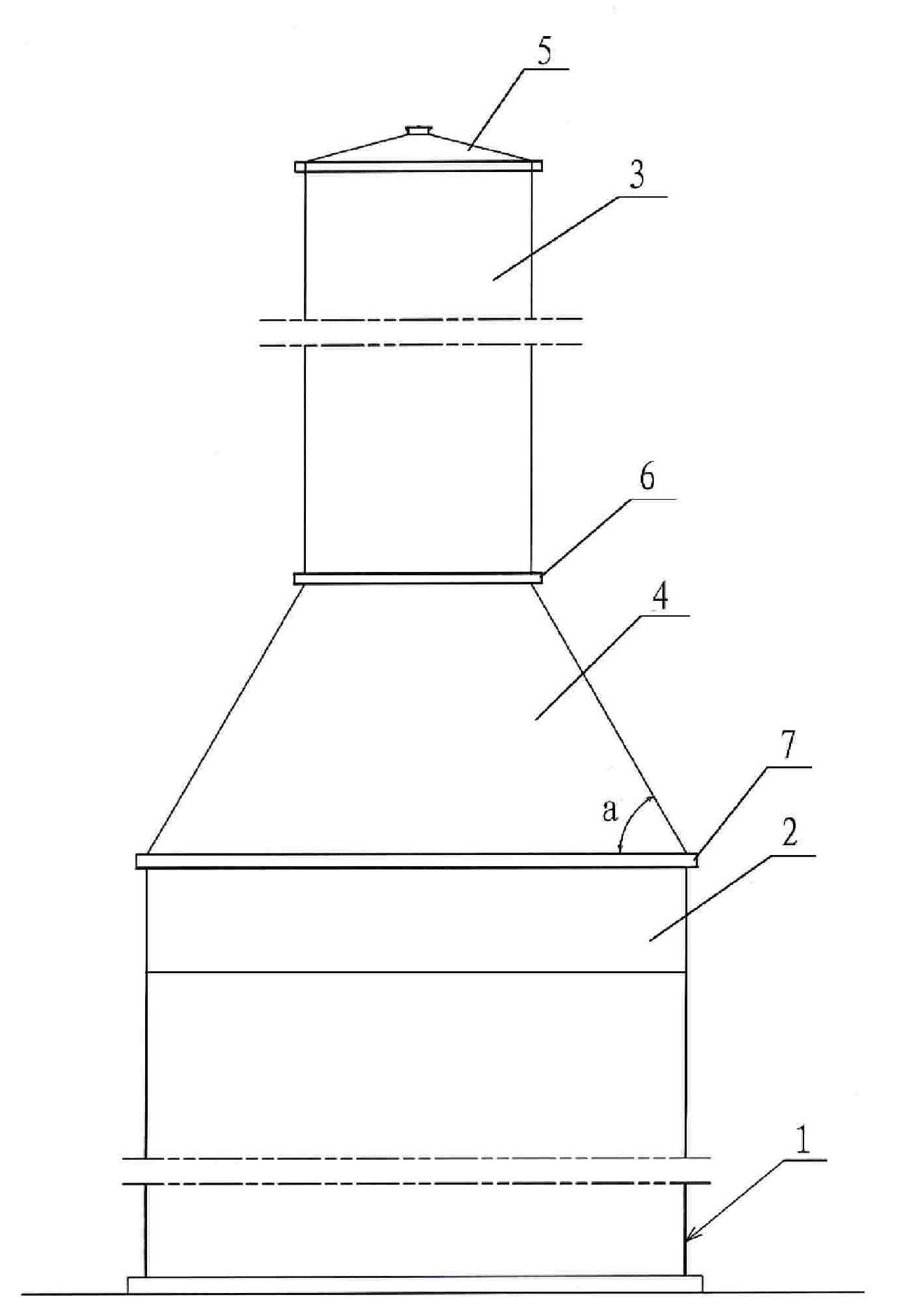

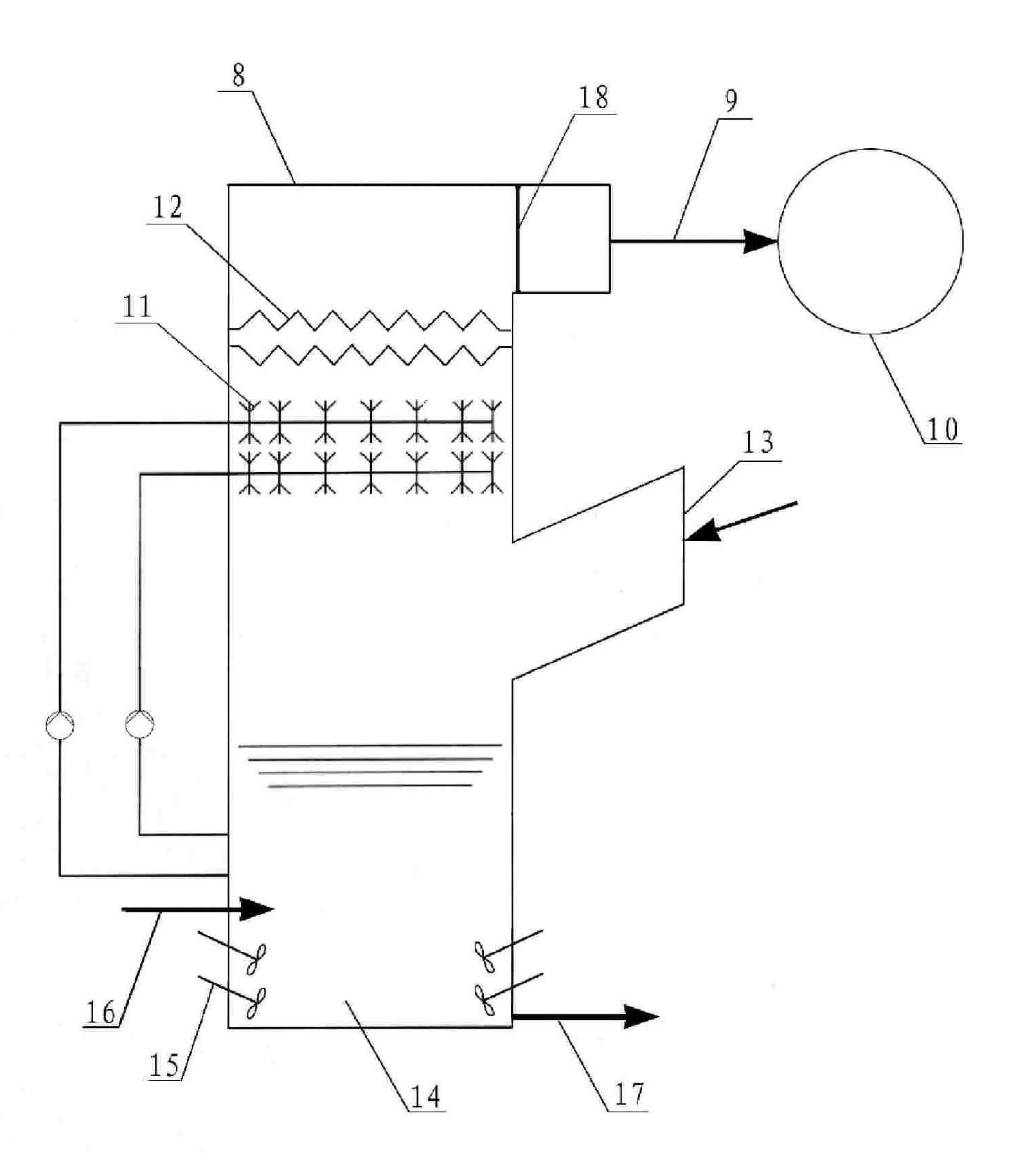

[0029] Referring to the embodiment shown in Figures 1 and 2, this method of continuous operation of the desulfurization absorption tower, the top of the absorption tower is connected with a flange baffle 8, the flue gas discharge port is connected with the main chimney 10 by the exhaust pipe 9, and the absorption tower A limestone slurry spraying device 11 and a demisting device 12 are arranged on the inner top, and a raw smoke inlet 13 is opened on the wall of the absorption tower below the spraying device. The bottom of the absorption tower is a slurry pool 14, and the slurry pool is equipped with Device 15 and forced oxidation device 16, the bottom of slurry tank is connected with gypsum slurry discharge pipe 17, it is characterized in that the steps are as follows:

[0030] Step 1, opening at the top of the absorption tower. When there is no pressure, the flange baffle 8 on the top of the absorption tower can be removed. When there is pressure, the opening can be covered w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com