High-strength case plank of transfer case

A high-strength, turnover box technology, which is applied in the jointing of wooden veneers, containers, biological packaging, etc., can solve the problems of low strength and low strength of particleboard or MDF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

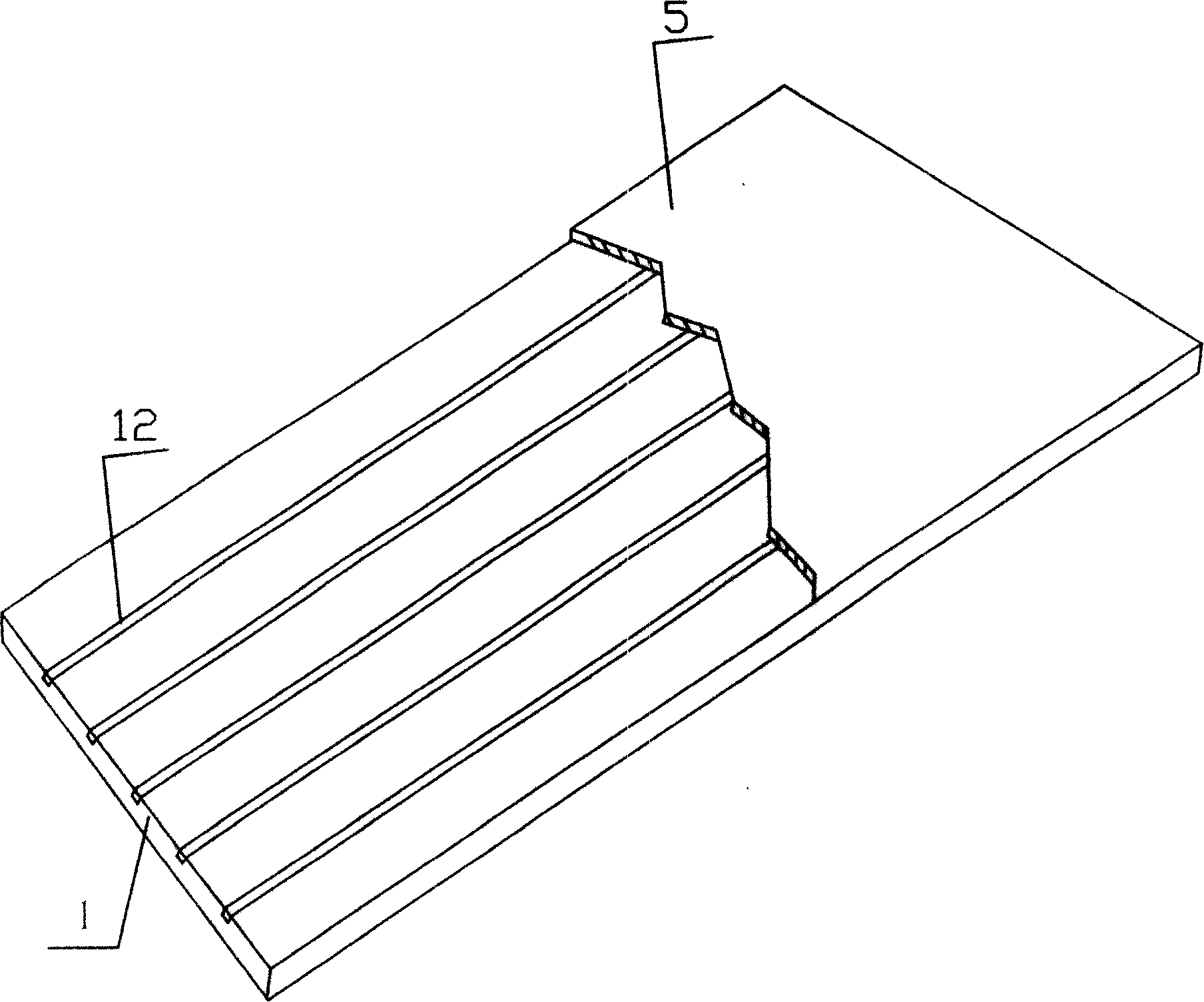

[0006] Embodiment 1. A high-strength multi-layer box board for a turnover box of the present invention is a board that is pressed by mixing broken wood chips and glue, and is heated with steam while pressing to form a high-temperature and high-pressure board-making process. Its characteristics The reason is: there is a reinforced metal mesh inside the wood chip and glue mixed board. Mix wood chips and glue to form a mixed raw material, add a layer of mixed material cloth and a piece of metal mesh, add a layer of mixed material on the metal mesh, then spread a second layer of metal mesh on the mixed material, and finally lay an upper layer on the second layer of metal mesh Mixed material; made of high-density density board after high temperature and high pressure, the board contains two layers of reinforced metal mesh separated. Such a high-strength box board has a strength increased by 5.5 times. In particular, the ability to resist bending and deformation has increased by mo...

Embodiment 2

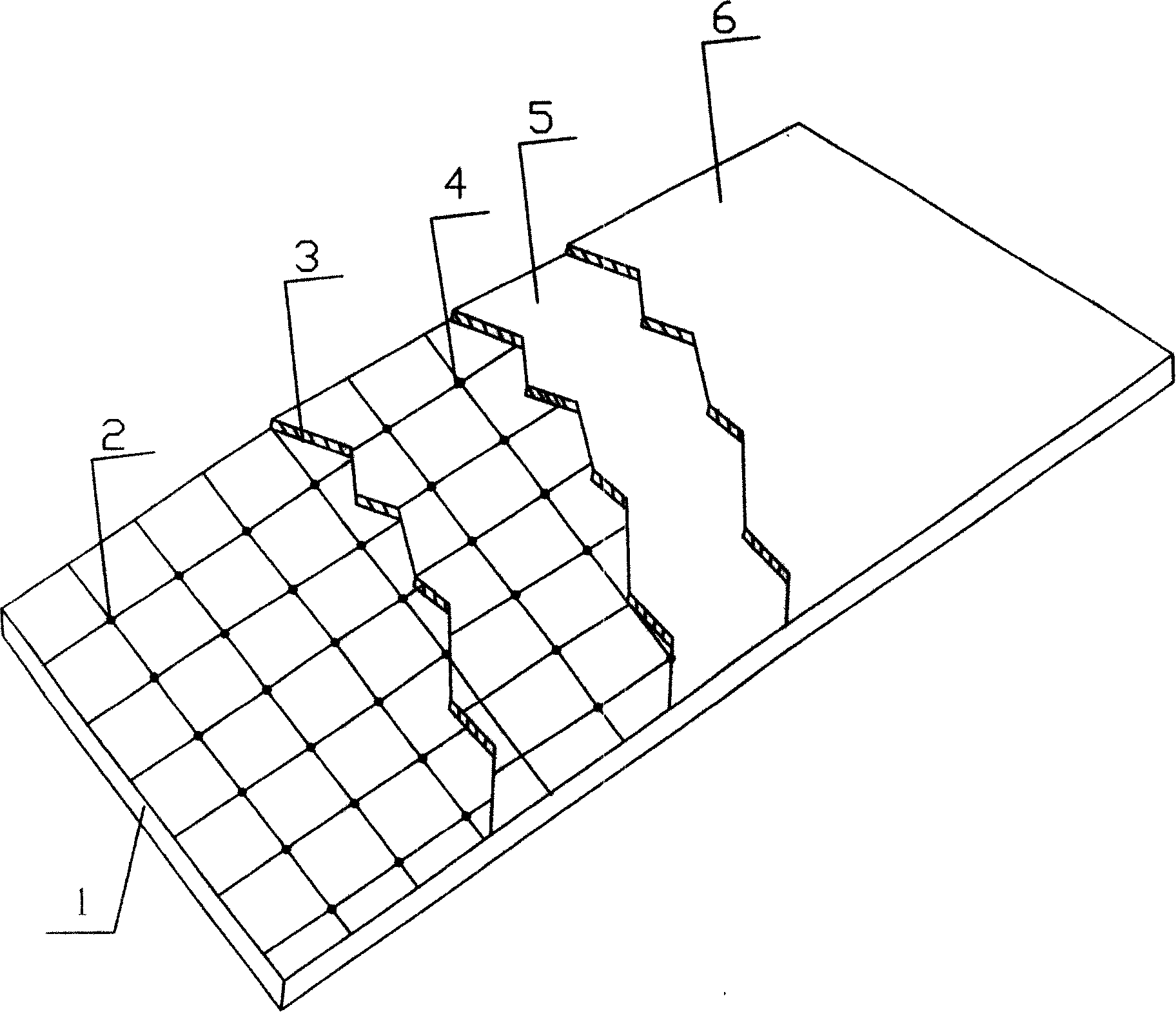

[0008] Embodiment 2, a high-strength box plate of the turnover box of the present invention, see figure 2 , is a board made of broken shavings and glue mixed with high temperature and high pressure. Woodworking shavings are mixed with glue to form a mixed stock. The bottom layer is a decorative surface, add a layer of mixture 1 on the decorative surface, cloth a layer of plastic mesh 2 on the mixture, add a layer of mixture 3 on the plastic mesh, and then lay a second layer of plastic mesh on the mixture 4. Lay the upper layer compound material 5 on the second layer of plastic mesh at last, and cover the upper layer decorative surface 6 on the upper layer compound material; high-density decorative particleboard is made through high temperature and high pressure, and the board contains two layers of reinforced plastic mesh separated from each other. Such a high-strength box board has a strength increased by 6 times. In particular, the ability to resist bending and deformatio...

Embodiment 3

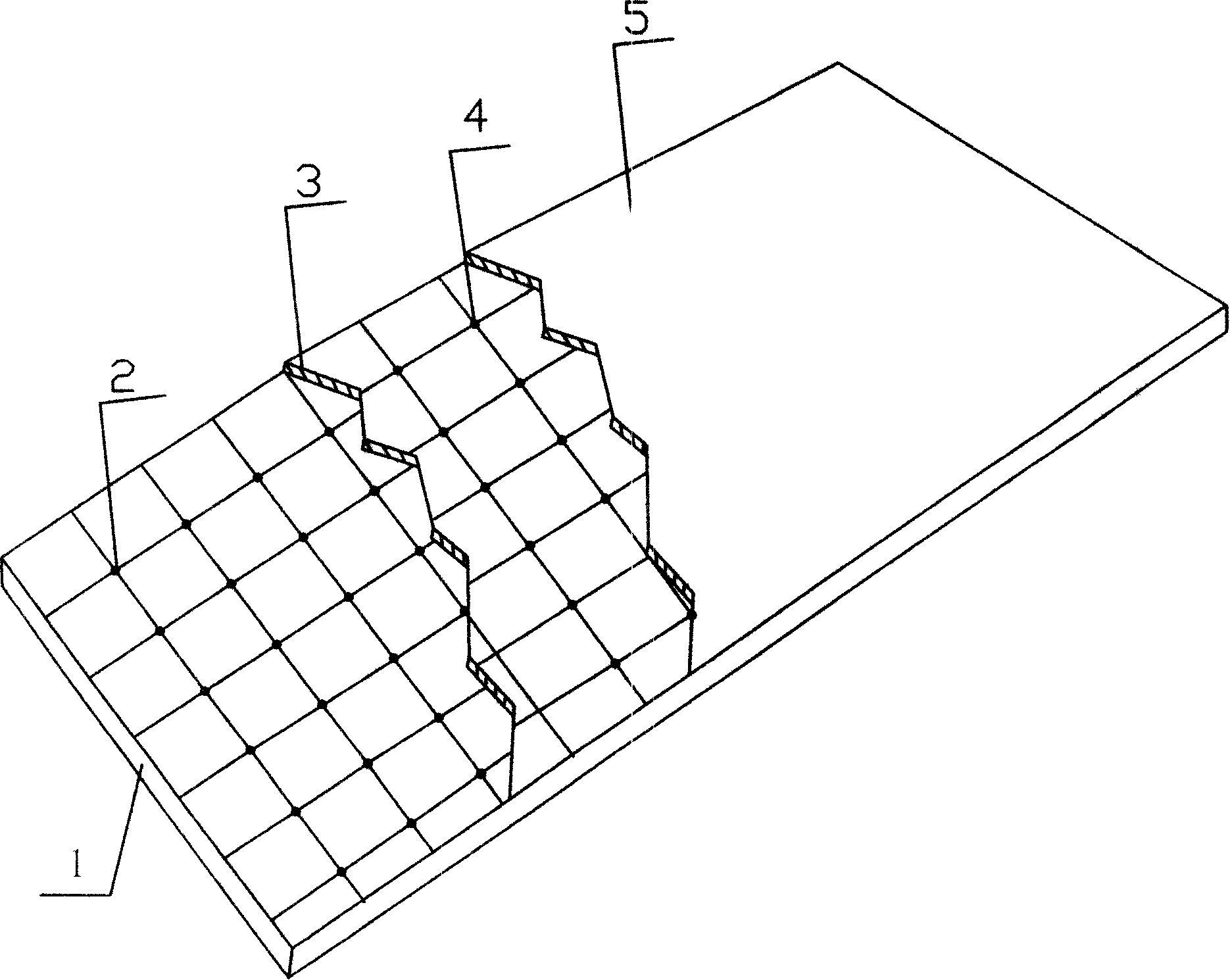

[0009] Embodiment three, a kind of high-strength box plate of the turnover box of the present invention, see figure 1 It is a mixture of broken wood fiber and glue obtained by crushing woodworking waste to form a mixed raw material. Add a layer of mixed material in the frame of the board-making mold, cloth a layer of glass fiber net on the mixed material, add another layer of mixed material on the glass fiber net, and then cloth a second layer of glass fiber net on the mixed material, and finally in the second The upper layer of mixture is laid on the first layer of glass fiber mesh; it is heated at 100 degrees by a press and pressed into a high-density density board, which contains two separate layers of reinforced glass fiber mesh. Such a high-strength box board has a strength increased by 5.1 times. In particular, the ability to resist bending and deformation has increased by more than 5 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com