Temperature lifting type molded coal drying kiln

A technology for drying kilns and briquettes, which is applied in the directions of drying solid materials, heating to dry solid materials, drying, etc. It can solve the problems of rapid evaporation, high energy consumption, high operating costs, and many equipments, and achieve the effect of uniform drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

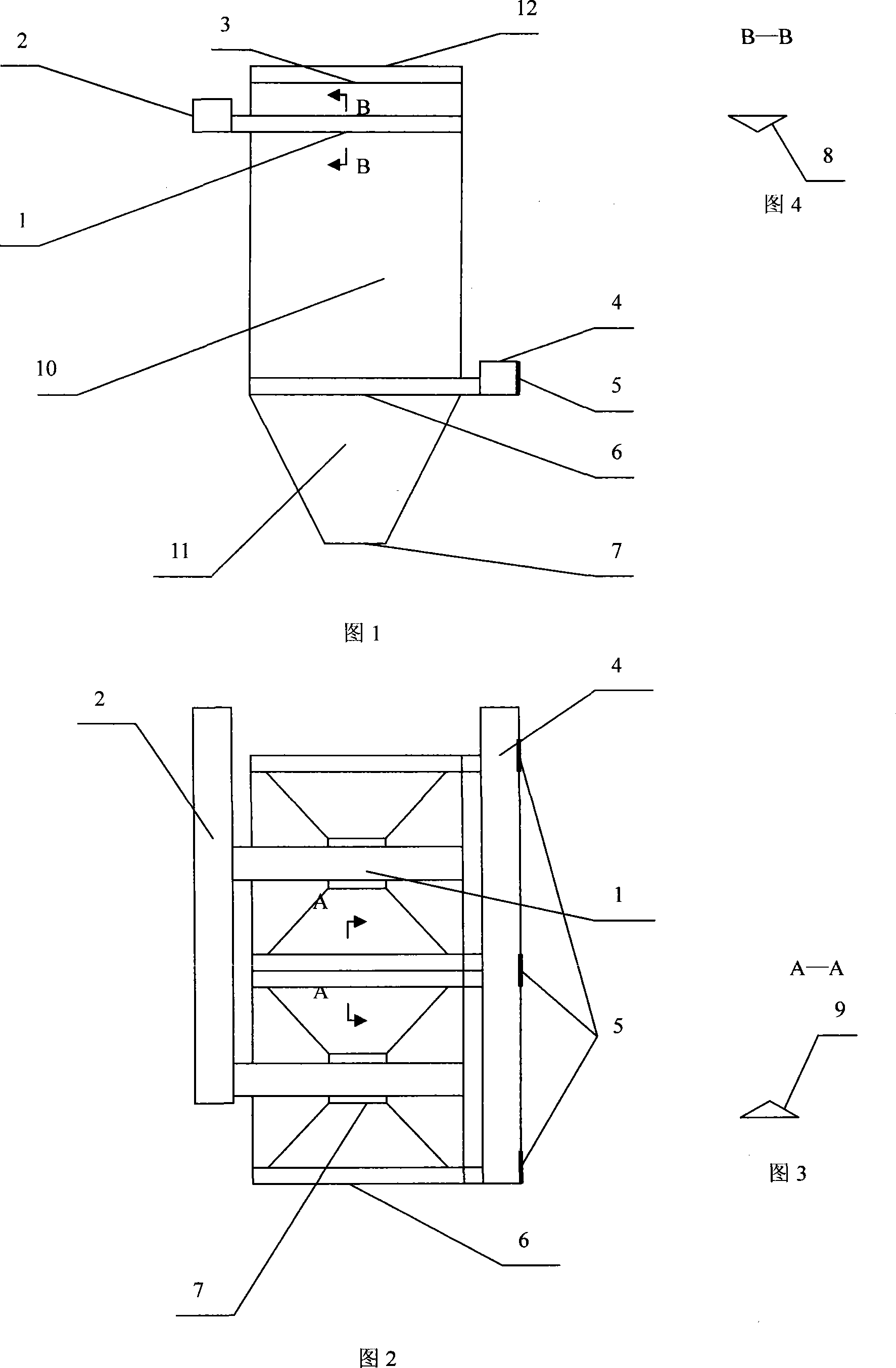

[0021] As shown in Figures 1, 2, 3, and 4: the heating type coal drying kiln includes: a kiln body (10), a distributor (12), a hopper (11), a hot air pipe (6), and a draft pipe (1), induced draft fan and dust collector; the kiln body (10) is a rectangular column kiln body, the briquette inlet (3) above the kiln body is equipped with a distributor (12), and the upper part of the kiln body is provided with several air induction pipes ( 1), the bottom of the air induction pipe is provided with an air intake (8). The section of the air induction pipe (1) is an inverted triangle. Each air induction pipe (1) is connected with the air induction fan and the dust collector through the main air induction pipe (2) outside the kiln body (10); several hot air pipes (6) are arranged at the lower part of the kiln body, and The air outlet (9) that imports kiln body hot blast is arranged, and its hot blast pipe (6) cross-section is triangular, and both sides of triangle upper part are air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com