Steam drying system for sludge

A drying system and steam technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of increasing mechanical failure rate, high sludge viscosity, and reducing drying rate, etc., to improve heat exchange efficiency, uniform drying effect, Effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

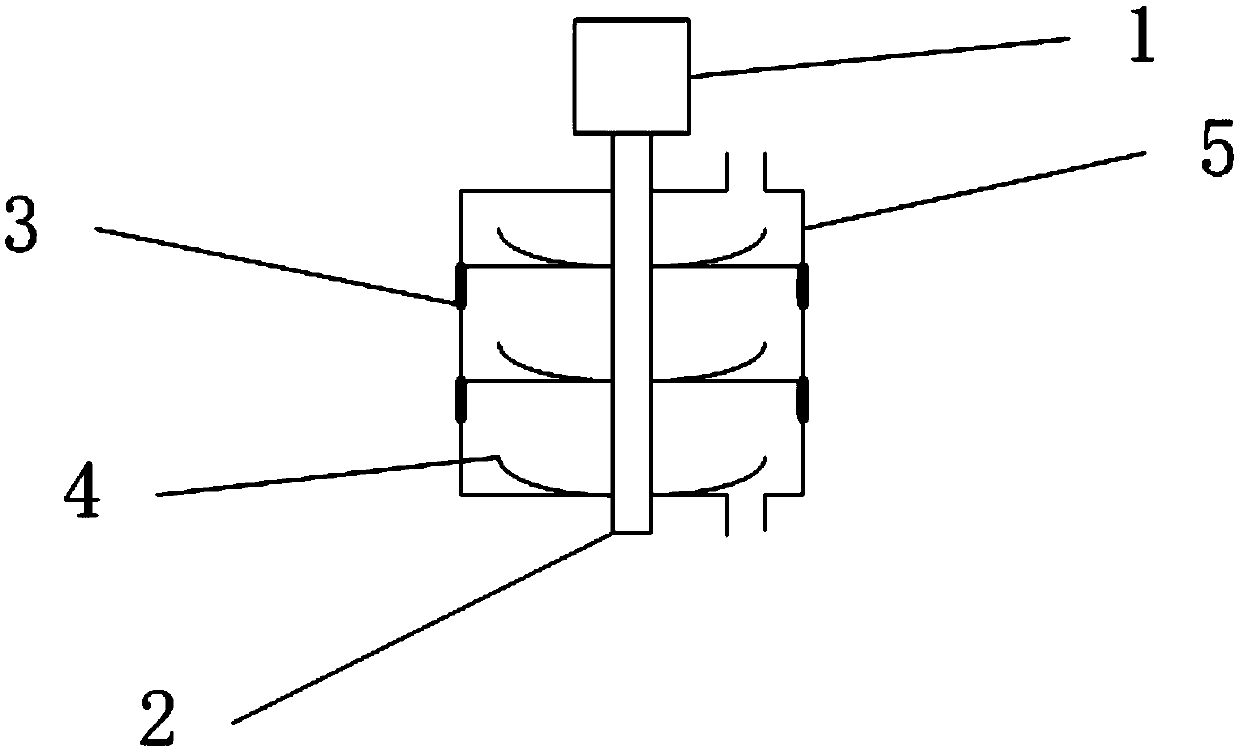

[0024] Such as figure 1 Shown, a kind of sludge steam drying system, it comprises:

[0025] the first means of transport;

[0026] A drying box, which includes a primary drying box and a secondary drying box, the feed end of the primary drying box is connected to the discharge end of the first transportation device, and the feeding end of the secondary drying box is connected to the The discharge end of the first-level drying box is connected, and several layers of vibrating screen drums 5 are arranged in the first-level drying box, and elastic plastic 3 is used to connect between adjacent two layers of screens, and each layer of vibrating screen drums 5 is provided with There is a crushing device, and the crushing device includes a rotating shaft 2, a blade 4 and a first drive motor 1, the rotating shaft passes through the center of the vibrating screen cylinder 5, the blade is arranged on the rotating shaft, and the first The driving motor is arranged on the top of the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com