Thermal dissipation type mass flowmeter and method for measuring mass flux

A technology of mass flowmeter and measurement method, which is applied in the direction of mass flow measurement device, indirect mass flowmeter, and measurement of fluid velocity by using thermal variables, etc., which can solve the problem that constant heating power cannot be realized, circuits are difficult to integrate into a set of circuits, and difficult to realize Problems such as the integration of power measurement method and temperature difference measurement method can achieve the effect of improving measurement accuracy and measurement range, good sensitivity and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

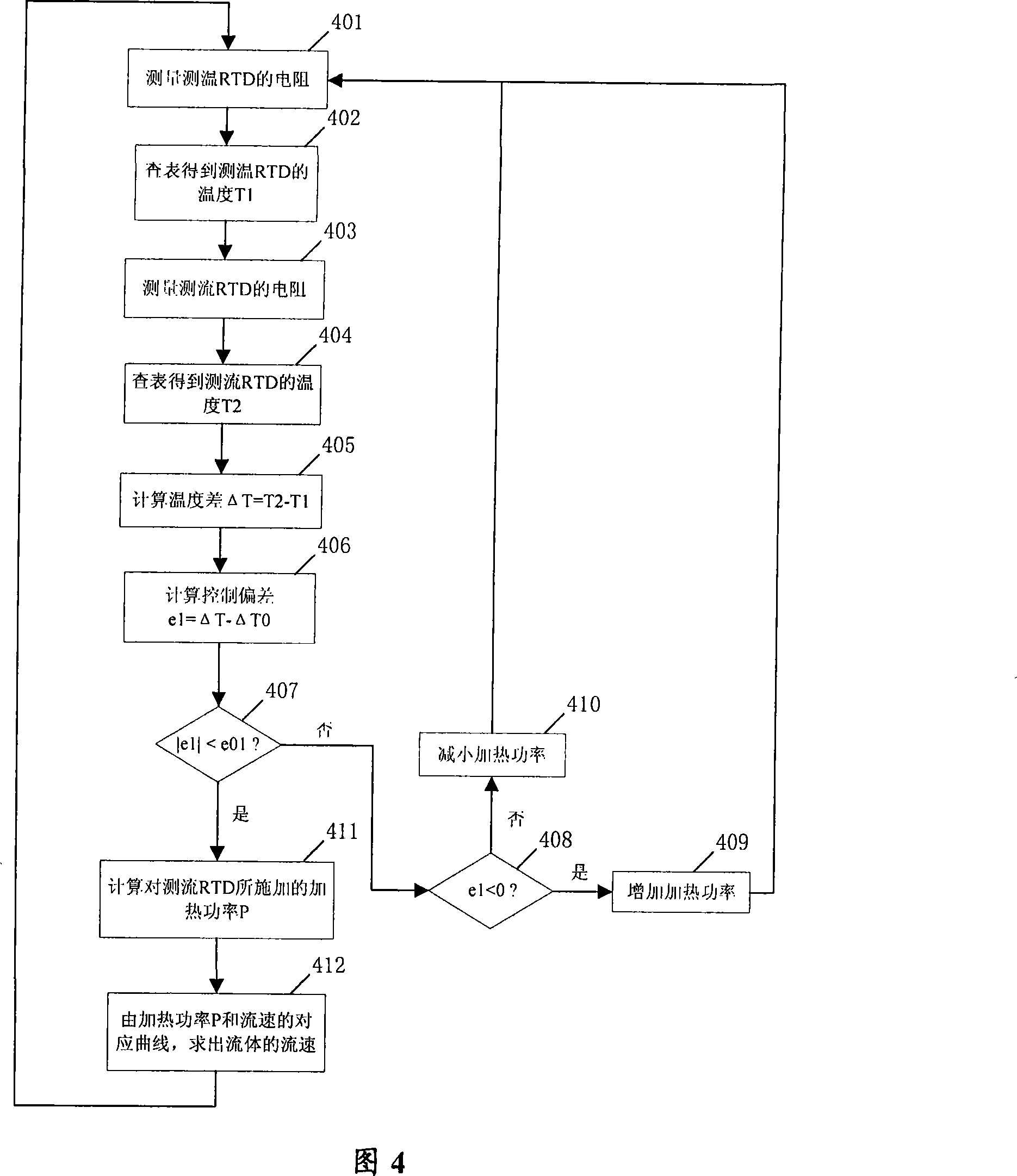

[0052] Please refer to Fig. 3, the heat dissipation mass flowmeter of the preferred embodiment of the present invention mainly includes: microprocessor 10, resistance measurement module 20, current measuring RTD30, temperature measuring RTD40, digital-to-analog converter 50 and voltage control voltage / current source 60 .

[0053] When performing flow measurement, the current measuring RTD30 and the temperature measuring RTD40 are placed in the fluid to be measured, and the microprocessor 10 controls the heating of the current measuring RTD30 through the digital-to-analog converter 50 and the voltage-controlled voltage / current source 60 . Specifically, the microprocessor 10 outputs a digital signal to the digital-to-analog converter 50, and the digi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com