Measuring instrument and method for temperature coefficient of optical glass refractive index

A technology of refractive index temperature and optical glass, applied in the field of optical instruments, can solve problems such as the specific structure and measurement method of the special temperature field are not given

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

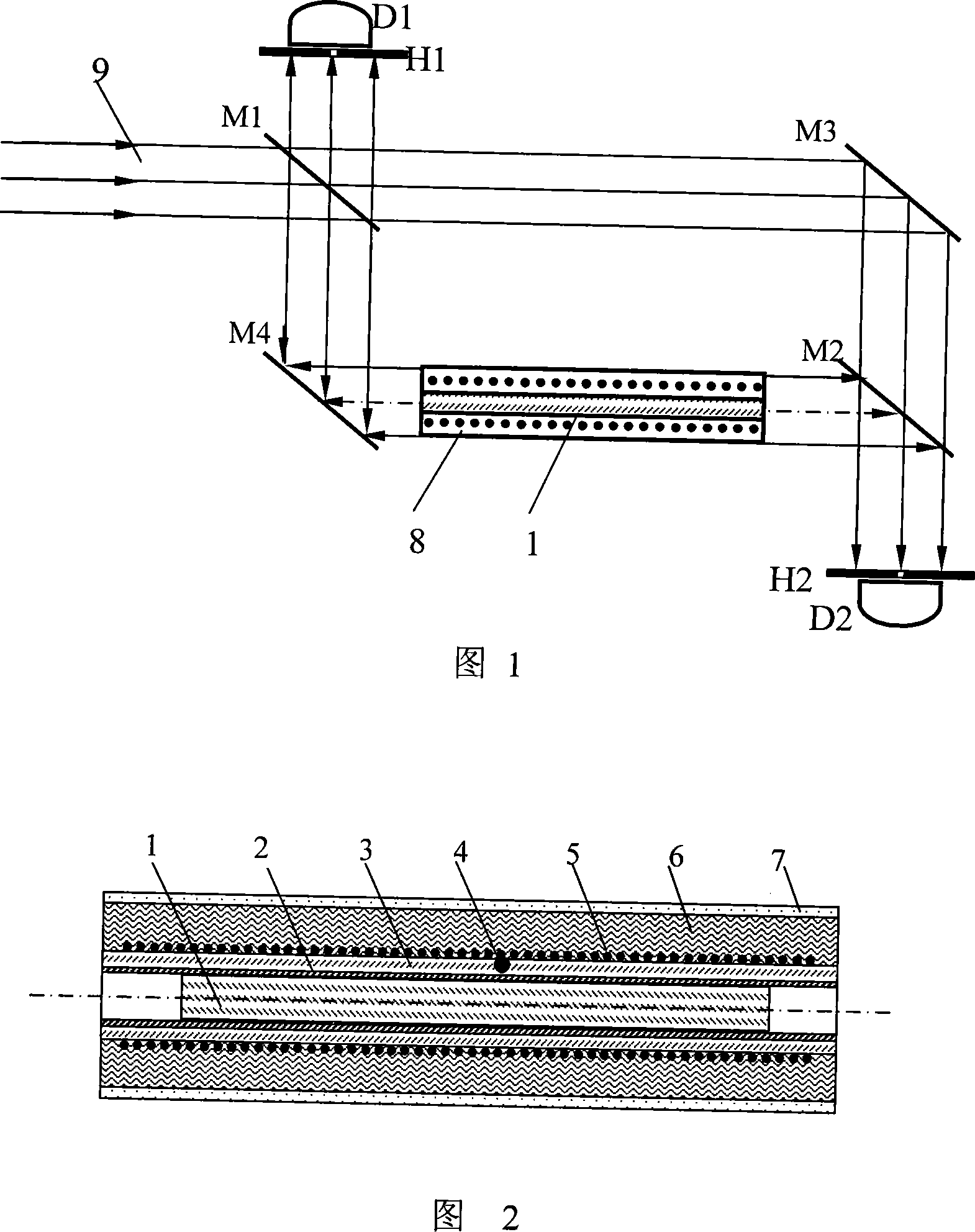

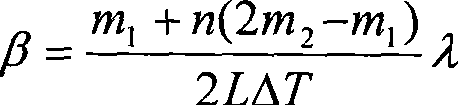

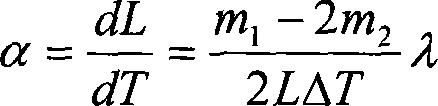

[0028] As shown in the figure, an optical glass refractive index temperature coefficient measuring instrument includes a He-Ne laser light source 9 and a Mach-Chendel interferometer composed of four mirrors M1, M2, M3, and M4. The two ends of the interferometer A first pinhole diaphragm H1 and a second pinhole diaphragm H2 are respectively arranged, and a silicon photodiode D1 for measuring the change of the interference fringe formed on the end surface of the rod is arranged near the first pinhole diaphragm H1, and the second pinhole diaphragm H1 A silicon photocell D2 for measuring the change of Mach-Chendel interference fringes is arranged near the column H2. A glass rod 1 with parallel ends is arranged in the interferometer. The sides of the glass rod 1 are polished, and the parallelism between the two ends is less than 10 seconds. The opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com