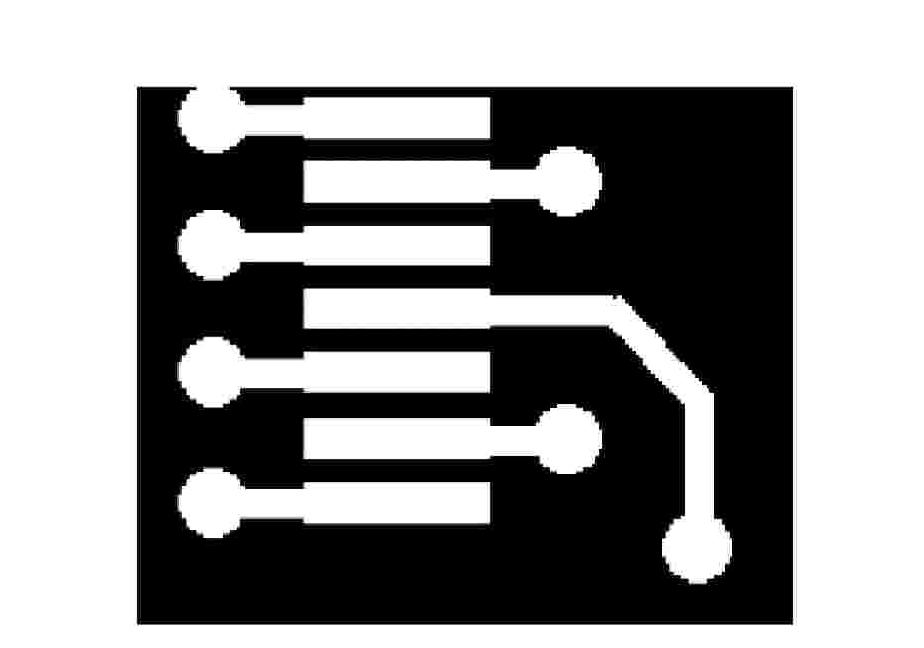

Printed circuit board image skeletonization method based on FPGA

A technology of printed circuit boards and image skeletons, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of time-consuming detection, loss of image features, and difficulty in real-time processing, so as to improve processing speed and release software resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

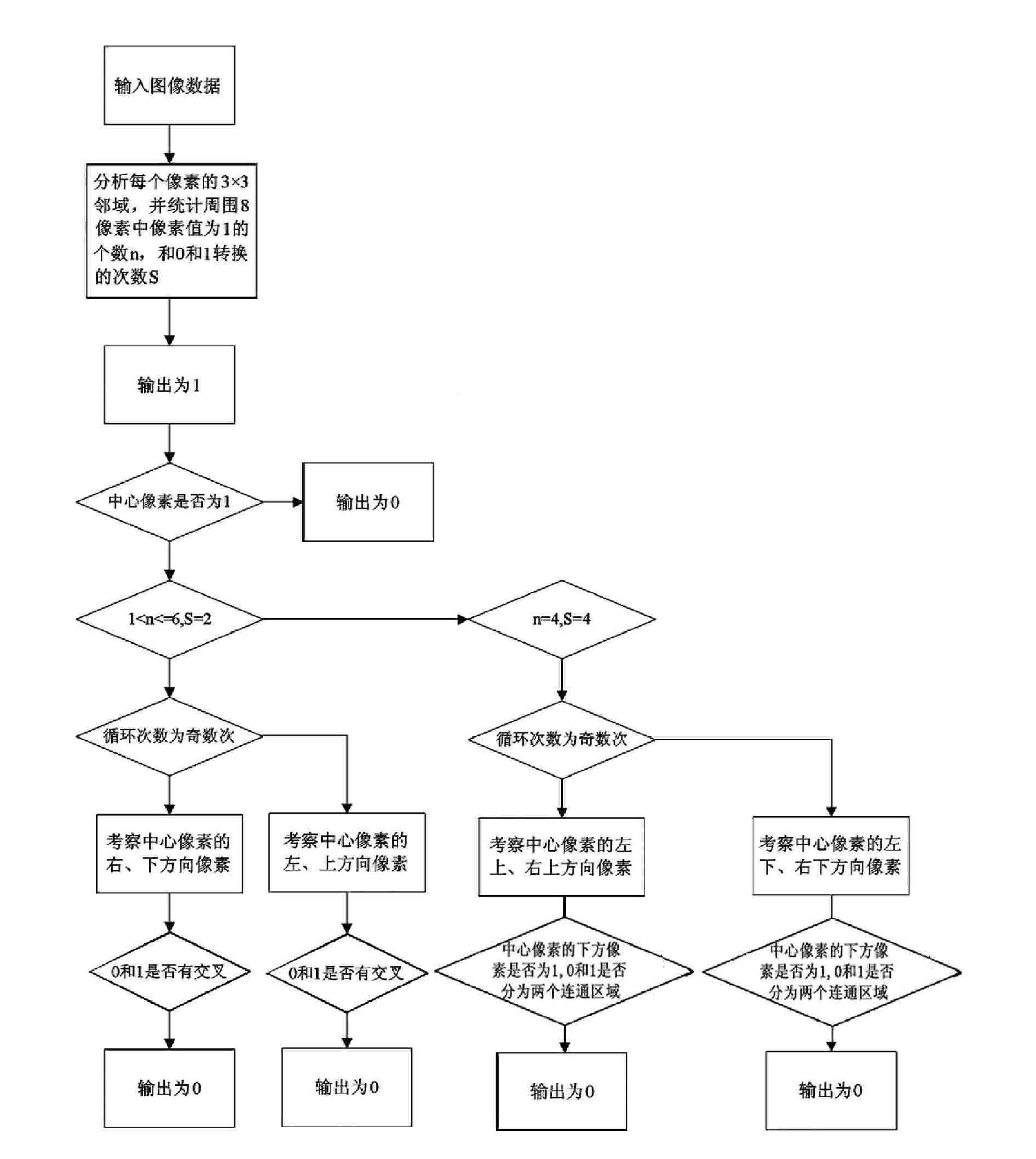

[0028] see example Figure 4 :

[0029] Step 1, input image data.

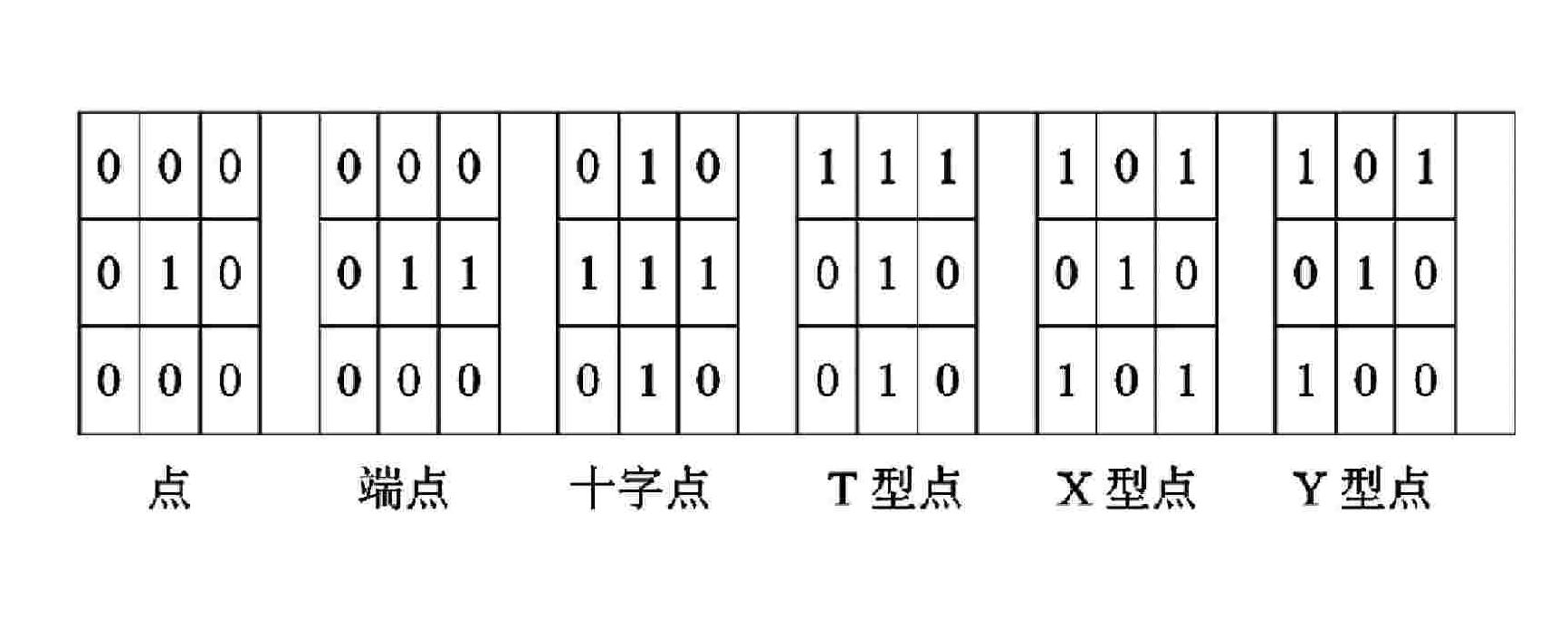

[0030] Step 2, analyze the 3 × 3 neighborhood of each pixel, and count the number n of the surrounding 8 pixels to the pixel value of 1, and the number of conversions S between 0 and 1, the output is 1, and the pixels that are reserved as 1 are counted.

[0031] Step 3, determine whether the center pixel is 1, if the output is 0, delete the center pixel.

[0032] Step 4, when 1

[0033] Step 5, when 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com