Method for preparing injectable hydroxyapatite nano-composite supramolecular hydrogel

A supramolecular hydrogel, hydroxyapatite technology, applied in the fields of biomedical materials and nano-functional materials, can solve the problems of unbearable, high brittleness, low strength of hydroxyapatite nanoparticles, etc., and achieves a safe preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

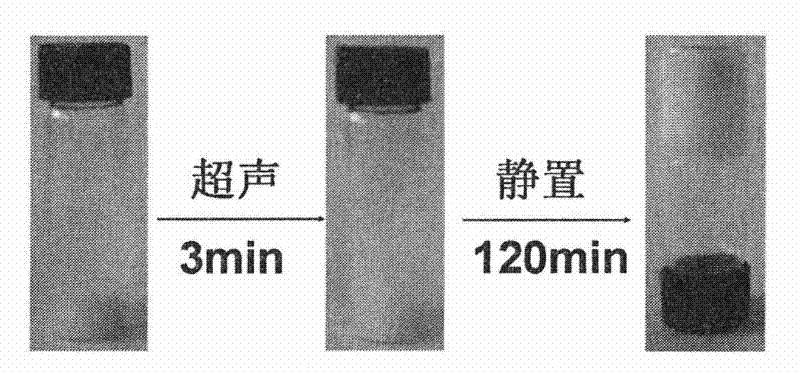

[0015] A preparation method for injectable hydroxyapatite nanocomposite supramolecular hydrogel, comprising the steps of:

[0016] 1) Take polyoxyethylene-polyoxypropylene-polyoxyethylene triblock polymer [Pluronic, Aldrich; molecular weight is 14600, the mass content of polyoxyethylene is 82.5%] 50mg, add the hydroxyapatite that particle size is 10nm Add 1 mg of stone nanoparticles, add 5 mL of water, and disperse ultrasonically (ultrasonic conditions: power 60w, frequency 20kHz, ultrasonic time 3min), to obtain a suspension;

[0017] 2) Take 400 mg of α-cyclodextrin (α-CD), add 5 mL of water, and prepare an aqueous solution of α-cyclodextrin with a mass concentration of 80 mg / mL;

[0018] 3) Mix the suspension obtained in step 1) with the α-cyclodextrin aqueous solution obtained in step 2) to obtain a mixed aqueous solution (the mass concentration of hydroxyapatite nanoparticles in the mixed aqueous solution is 0.1 mg / mL, Pluronic triblock The concentration of the polymer i...

Embodiment 2

[0021] 1 mg of hydroxyapatite nanoparticles with a particle size of 10 nm in Example 1 was replaced with 5 mg of hydroxyapatite nanoparticles with a particle size of 200 nm. All the other steps are the same as in Example 1.

Embodiment 3

[0023] 10 mg of hydroxyapatite nanoparticles with a particle size of 300 nm was used instead of 1 mg of hydroxyapatite nanoparticles with a particle size of 10 nm in Example 1. All the other steps are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com