Correlated measuring method for ion average velocity of orienting plasma beam

A plasma and average velocity technology, applied in radiation measurement, measurement device, X / γ / cosmic radiation measurement, etc., can solve the problems of low precision, cumbersome measurement process, inability to obtain microsecond magnitude, etc., and achieve measurement results. The effect of small error and simple measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

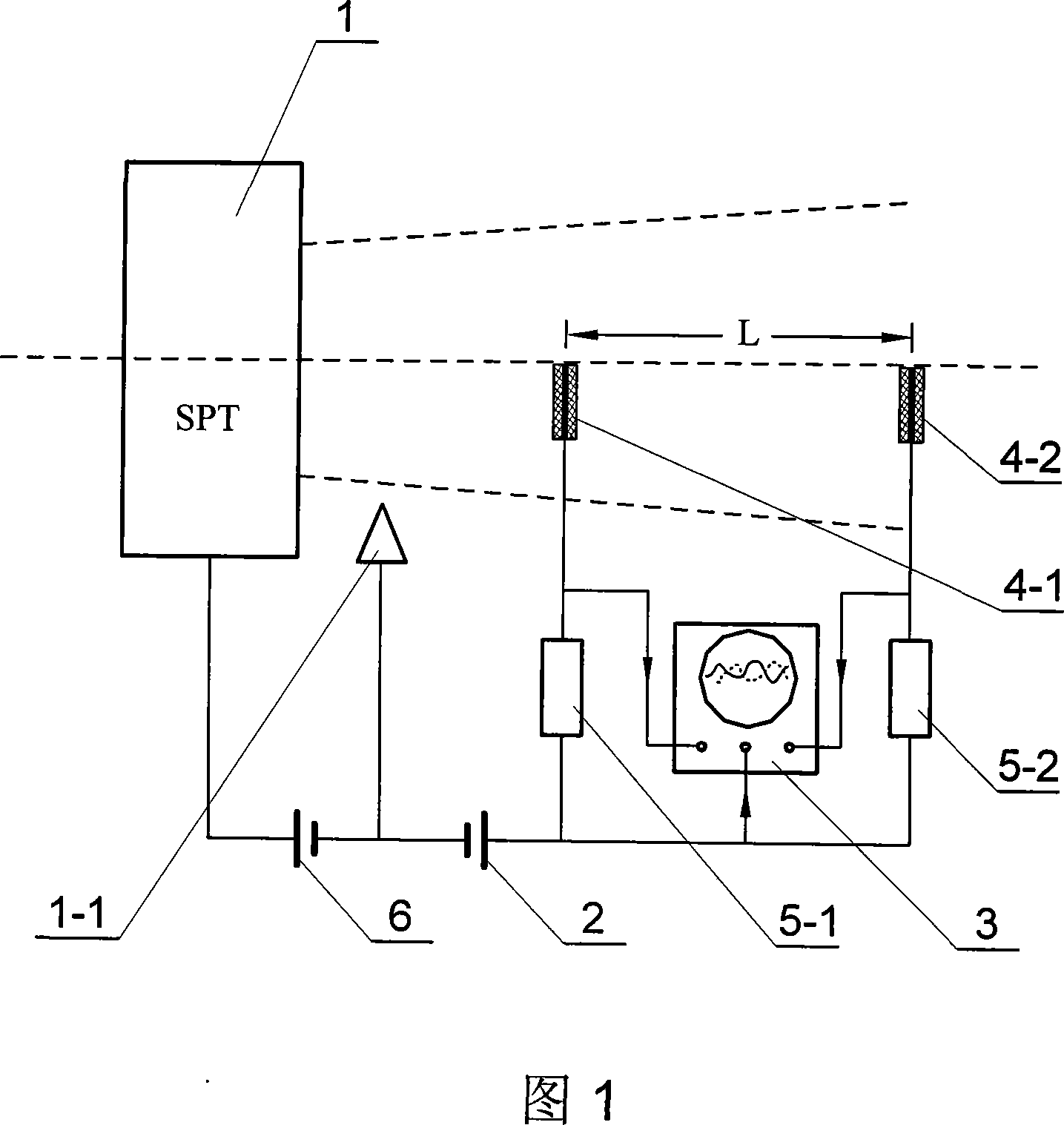

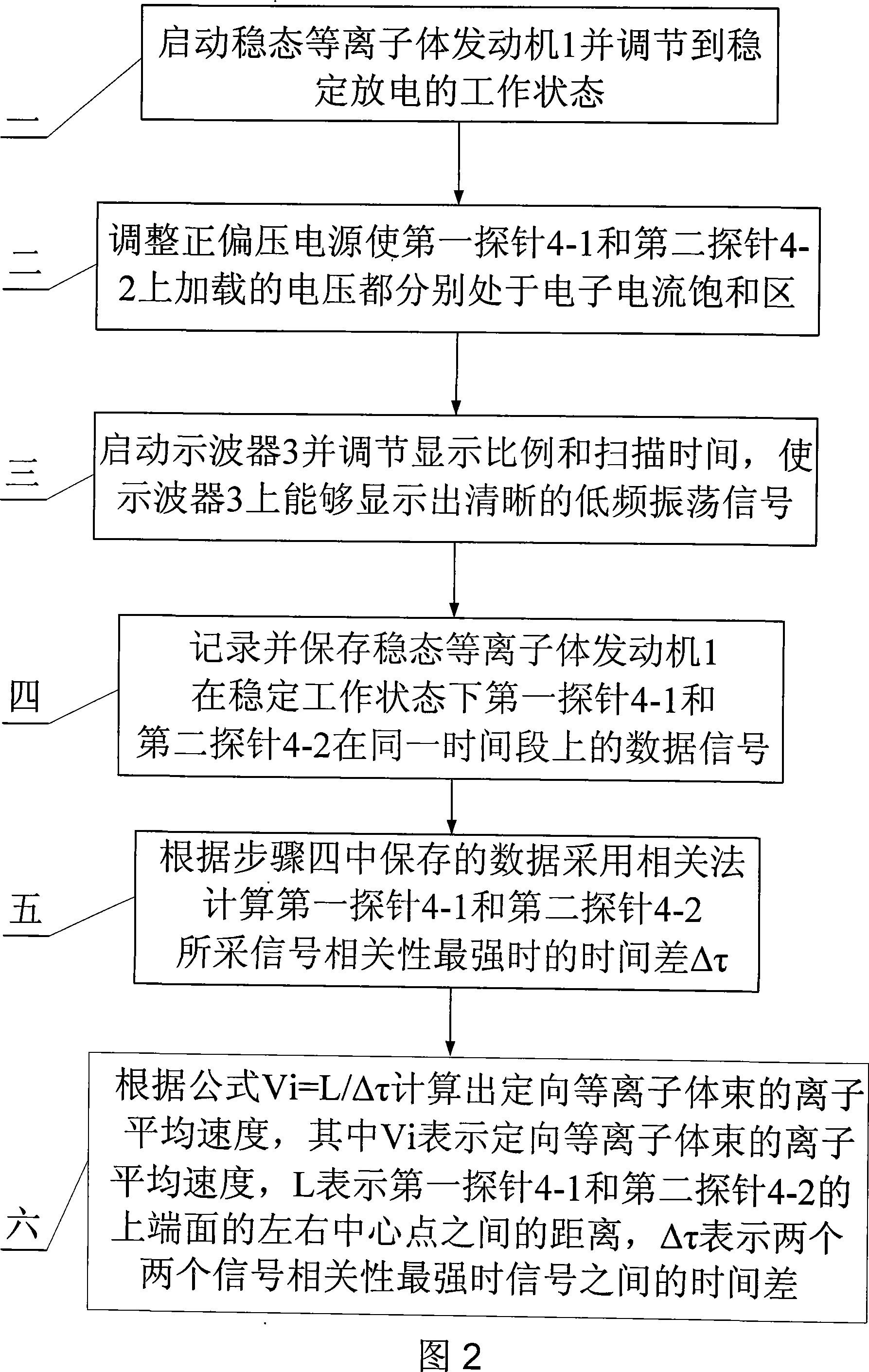

[0017] Specific Embodiment 1: Referring to Fig. 1 and Fig. 2, the method for completing the present embodiment adopts the device with the following structure, which consists of a steady-state plasma engine 1, a positive bias power supply 2, an oscilloscope 3, and a first probe 4-1 , the second probe 4-2, the first resistance 5-1, the second resistance 5-2 and the power supply 6, the first probe 4-1 and the second probe 4-2 are respectively set in the steady state plasma In the plume area of the engine 1, the left and right central points of the upper end surfaces of the first probe 4-1 and the second probe 4-2 are all located on the upper and lower central axes of the steady-state plasma engine 1, and the first probe 4- The output end of 1 and the first end of the first resistance 5-1 are connected with the first input end of the oscilloscope 3, and the output end of the second probe 4-2 and the first end of the second resistance 5-2 are connected with the first end of the se...

specific Embodiment approach 2

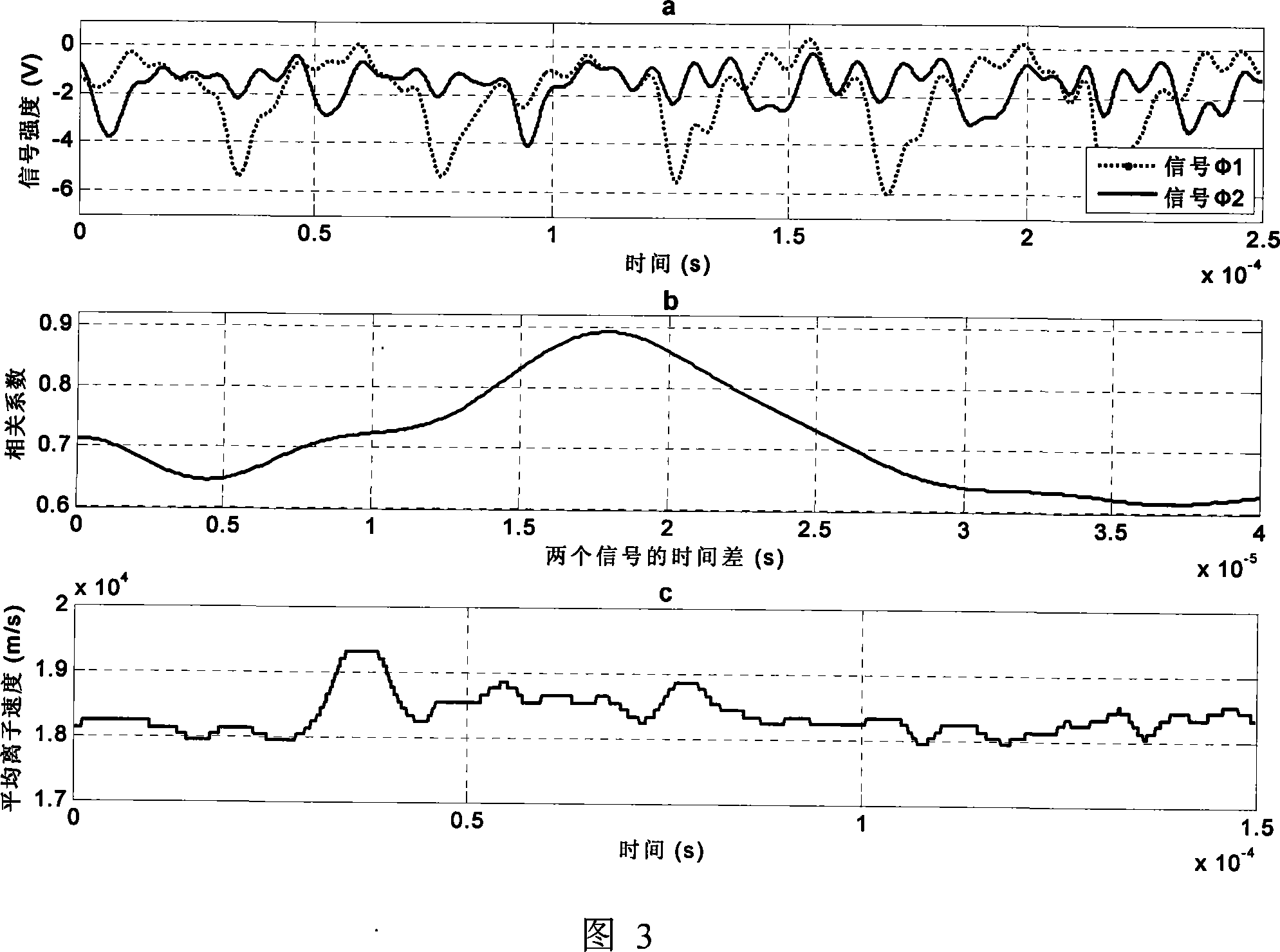

[0025] Specific embodiment two: referring to Fig. 3, the difference between this embodiment and specific embodiment one is that it is realized by the following steps:

[0026] Step 1. Start the steady-state plasma engine 1 and adjust it to a stable discharge working state where the discharge voltage Up is 300V and the anode gas supply flow rate is 3mg / s. From then on, a certain density of plasma fills the plume area;

[0027] Step 2. Start the positive bias power supply 2. The positive bias power supply 2 can adopt a 0-100V adjustable DC stabilized power supply. Adjust the output value of the positive bias power supply 2 to 40V. The left and right central points are set at a distance of 15 cm from the upper and lower central points of the steady-state plasma engine 1, and the left and right central points of the upper end surface of the second probe 4-2 are arranged at a distance from the upper and lower central points of the steady-state plasma engine 1. The distance is 48cm;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com