Correlated measuring method for ion average velocity of orienting plasma beam

A technology of plasma and average velocity, applied in radiation measurement, measuring device, X/γ/cosmic radiation measurement, etc., can solve the problems of low precision, cumbersome measurement process, large error, etc. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

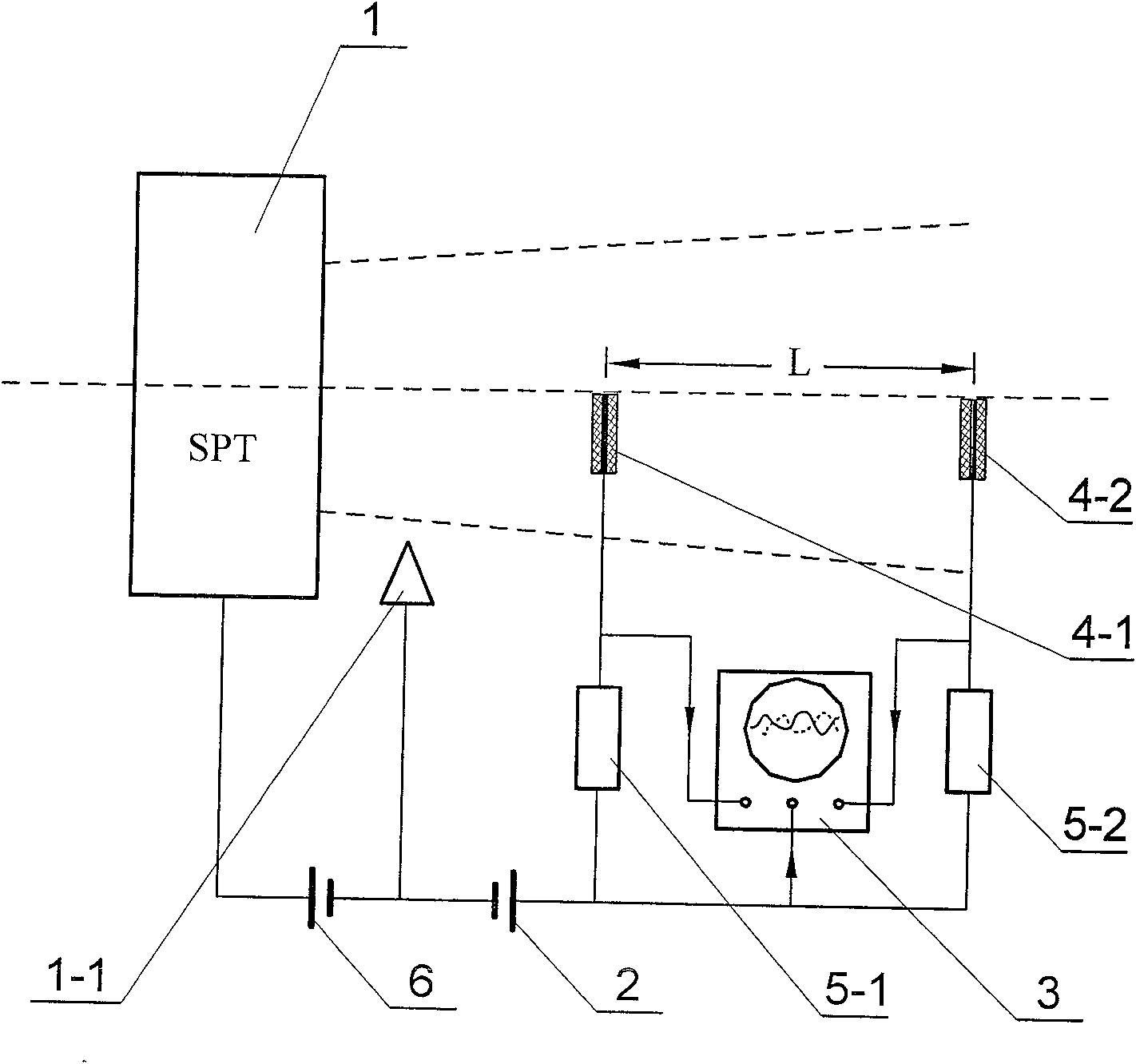

[0017] Specific implementation mode one: see figure 1 , figure 2 , the method for completing the present embodiment adopts a device with the following structure, which consists of a steady-state plasma engine 1, a positive bias power supply 2, an oscilloscope 3, a first probe 4-1, a second probe 4-2, Composed of resistance 5-1, second resistance 5-2 and power supply 6, the first probe 4-1 and the second probe 4-2 are respectively arranged in the plume area of the steady-state plasma engine 1, the first probe The left and right central points of the upper end surfaces of the needle 4-1 and the second probe 4-2 are all located on the upper and lower central axes of the steady-state plasma engine 1, and the output end of the first probe 4-1 and the first resistor 5-1 The first end of the first end of the oscilloscope 3 is connected to the first input end of the oscilloscope 3, the output end of the second probe 4-2 and the first end of the second resistance 5-2 are connected ...

specific Embodiment approach 2

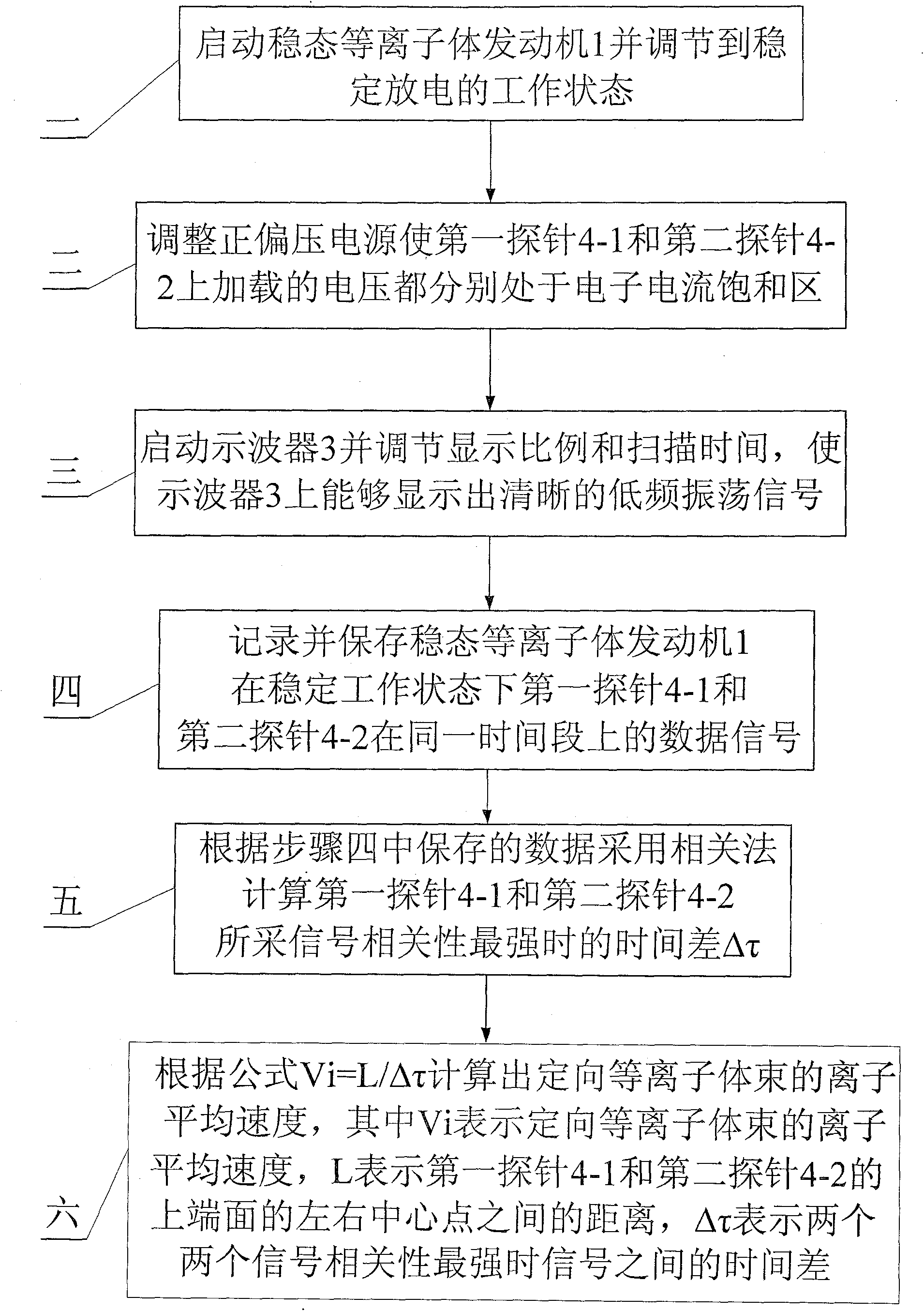

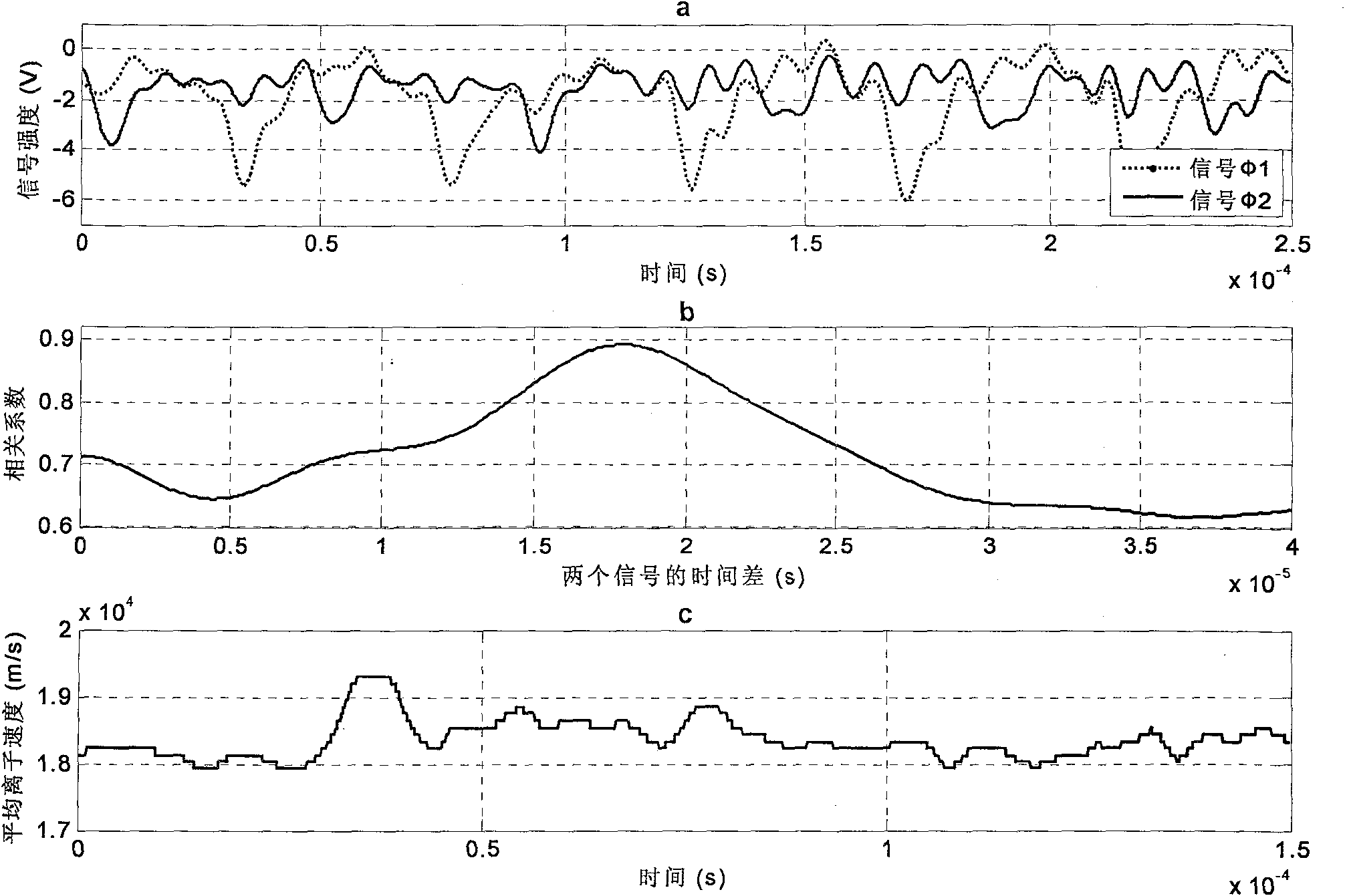

[0025] Specific implementation mode two: see image 3 , the difference between this embodiment and the first embodiment is that it is realized by the following steps:

[0026] Step 1. Start the steady-state plasma engine 1 and adjust it to a stable discharge working state where the discharge voltage Up is 300V and the anode gas supply flow rate is 3mg / s. From then on, a certain density of plasma fills the plume area;

[0027] Step 2. Start the positive bias power supply 2. The positive bias power supply 2 can adopt a 0-100V adjustable DC stabilized power supply. Adjust the output value of the positive bias power supply 2 to 40V. The left and right central points are set at a distance of 15 cm from the upper and lower central points of the steady-state plasma engine 1, and the left and right central points of the upper end surface of the second probe 4-2 are arranged at a distance from the upper and lower central points of the steady-state plasma engine 1. The distance is 48cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com