Device for correcting illumination homogeneity

A technology for uniformity correction and illumination field, which is applied in photolithography process exposure devices, microlithography exposure equipment, etc. It can solve problems such as increasing the complexity of the correction system, and achieve the effect of avoiding light leakage and shadows and controlling uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

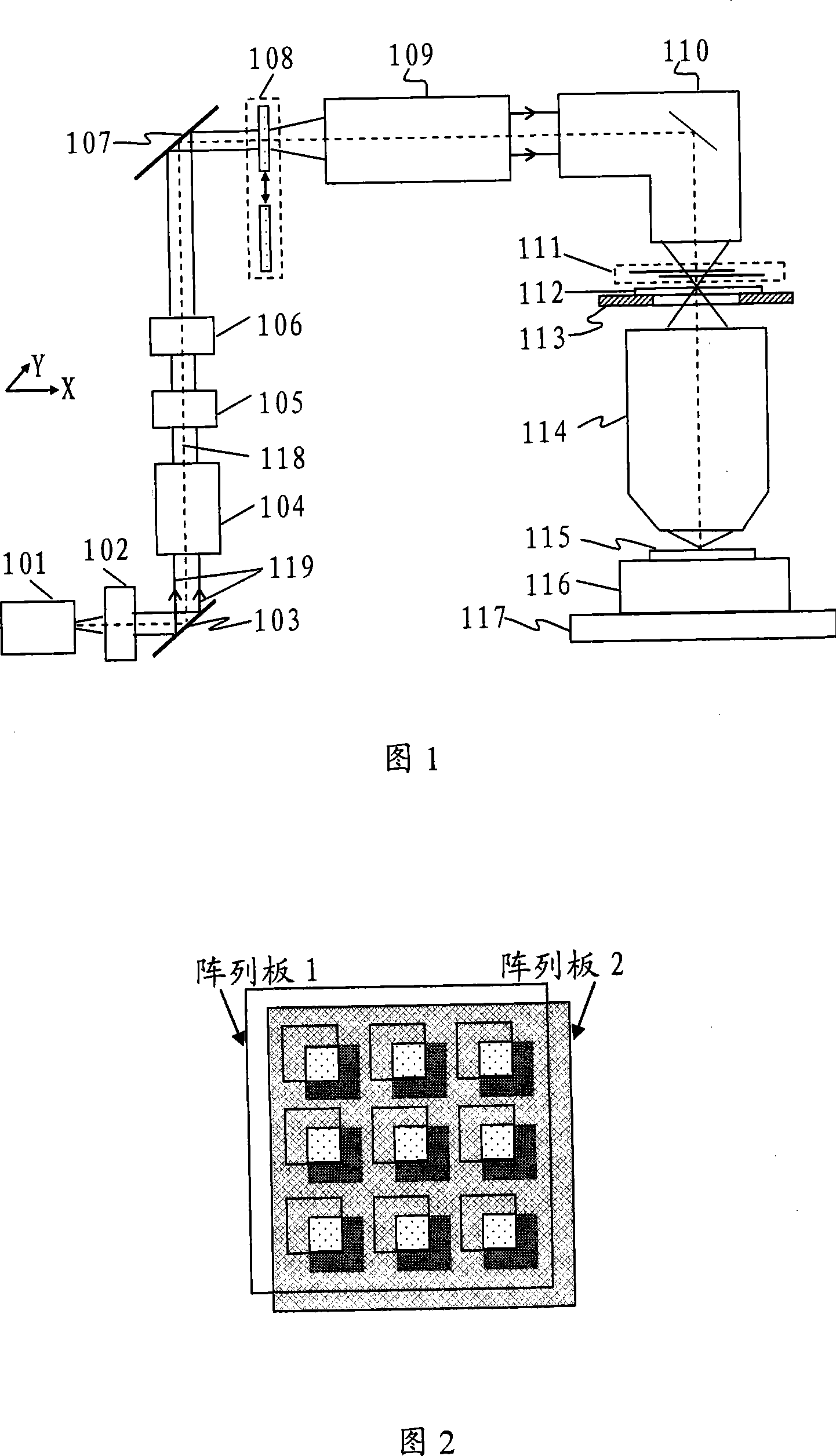

[0034] As shown in FIG. 1 , it is a schematic structural diagram of an exposure projection system applied to the uniformity correction device of the present invention. Wherein, the light source 101 generates a laser beam for exposure, which may be a laser light source of 248nm, or 193nm, or other wavelengths. The beam 119 emitted by the light source is first collimated by the beam expander 102, and the elliptical light is converted into a circular beam; the reflector unit 103 can be a single reflector, or a complex transmission system comprising multiple reflectors, which The laser beam 119 emitted from the beam expander 102 is transmitted to the beam positioning unit 104; the beam positioning unit 104 can correct the incident position and angle of the beam 119 by sampling and analyzing the beam; then the beam 119 passes through the energy used to control the lighting system The adjustable optical attenuator 105 and the energy monitoring unit 106; after passing through the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com