Airplane simulation cabin butted with special vehicle in airport

A special vehicle and aircraft simulation technology, applied in the field of docking aircraft simulation cabins, can solve problems such as ignorance, danger, increased work difficulty and risk, etc., to achieve realistic training effects, ideal effects, and improve flexibility and adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make it easier for those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

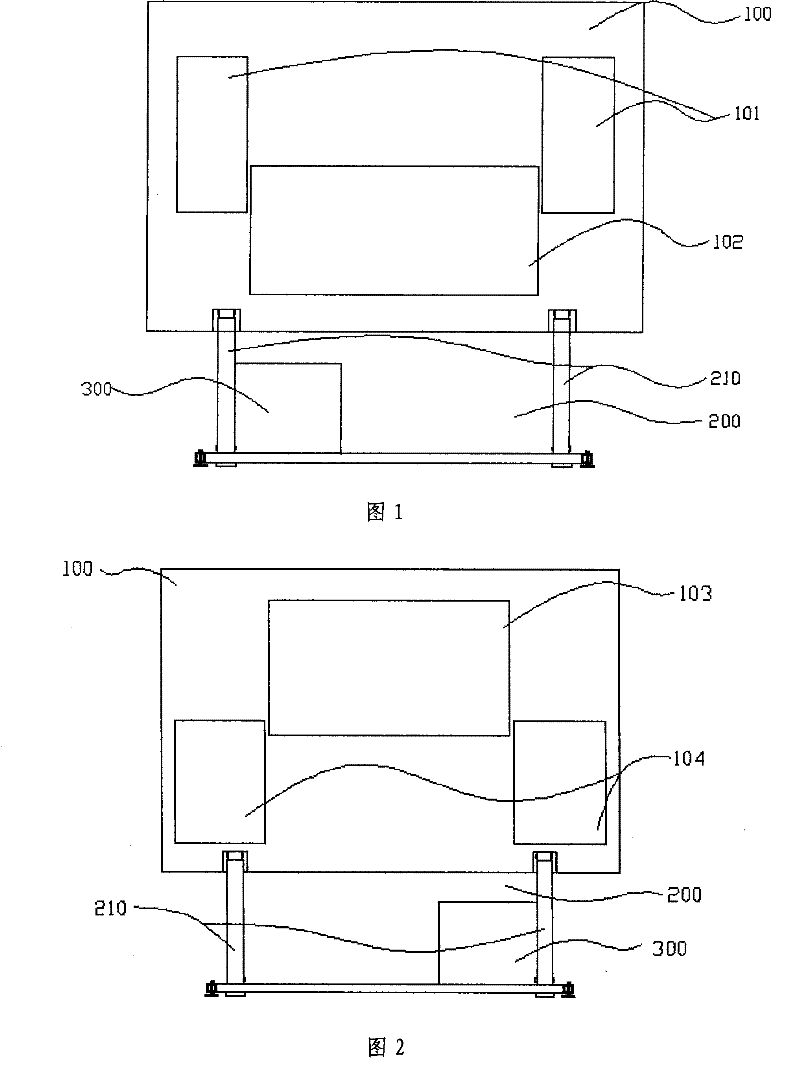

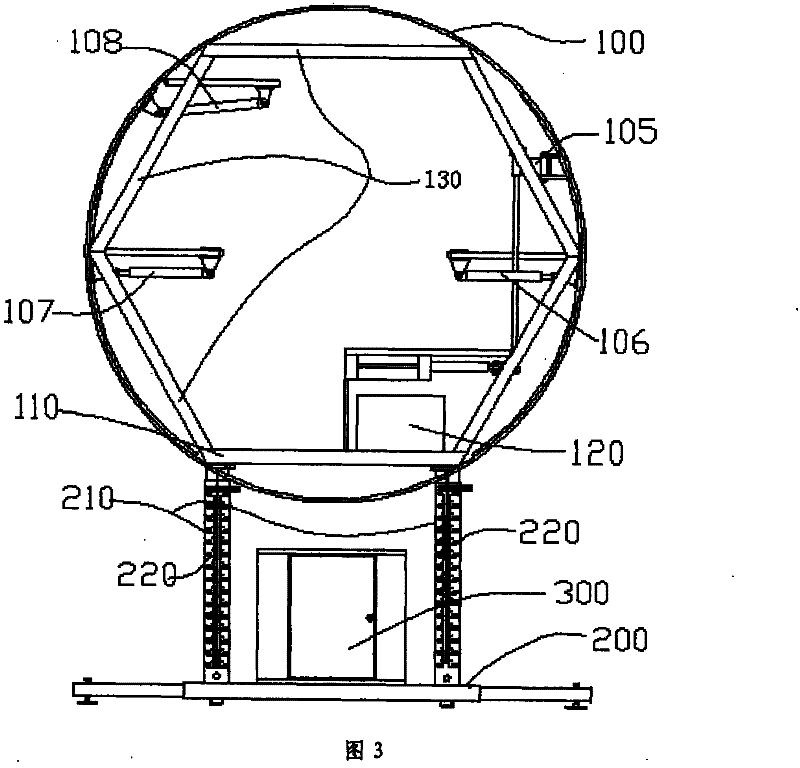

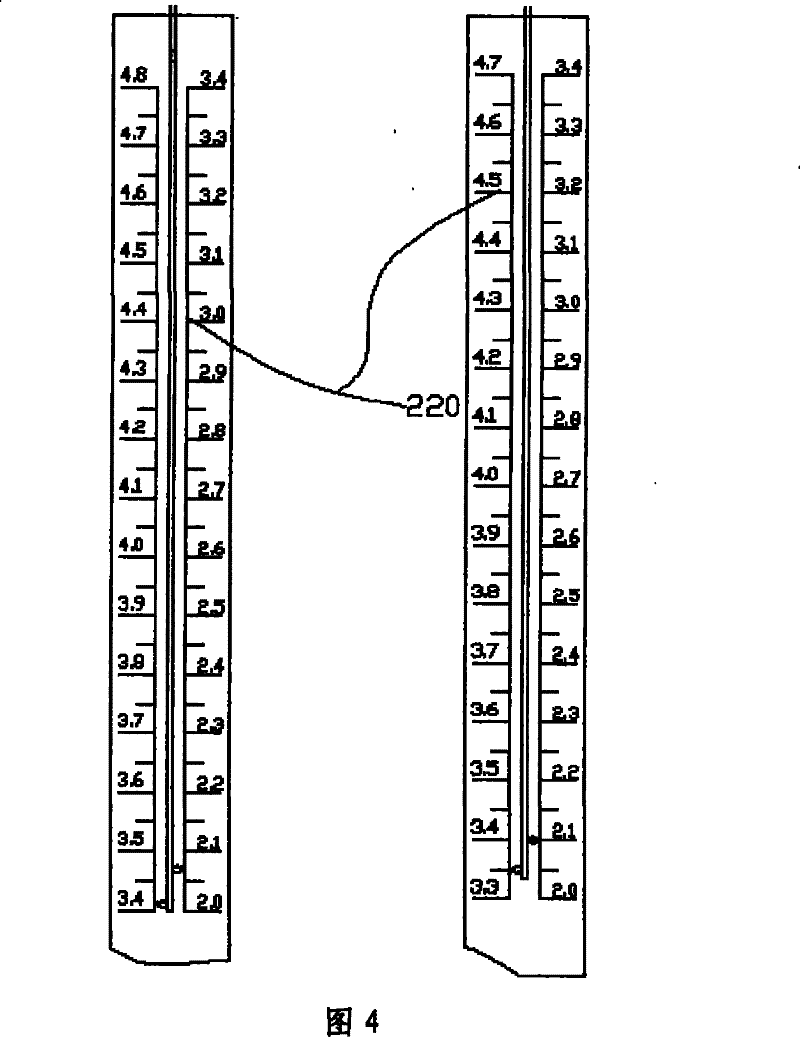

[0021] The composition of the space shuttle includes a six-degree-of-freedom motion platform and a simulated cockpit. Its shape and characteristics are the same as those of the space shuttle cockpit. The layout of the aircraft cabin includes portholes, instruments and various equipment to create a real space shuttle cabin environment. For training in realistic environments such as figure 1 , 2 As shown in 3 and 3, the aircraft simulation cabin 100 established for docking with a special vehicle is cylindrical in shape as a whole, and the cylindrical cabin 100 is provided with a multilateral support 130 to firmly support the cabin 100. The lower part of the cabin body 100 is provided with a support platform 110 , and the two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com