High-strength novel hollow insulation composite pipe

A composite tube, high-strength technology, applied in the direction of insulators, electrical components, circuits, etc., can solve complex, safety-affecting, outer tube cracking and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

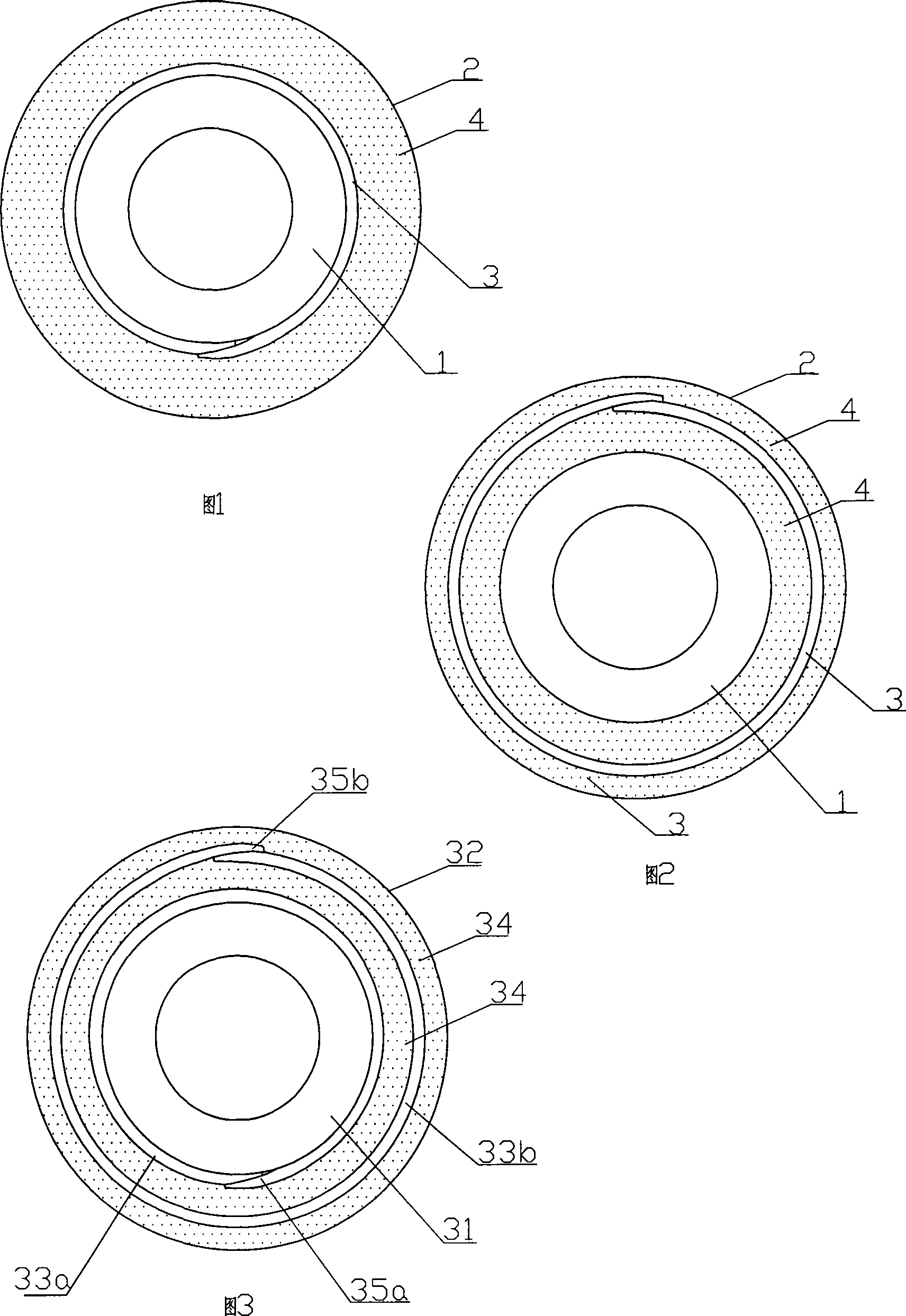

Embodiment 1

[0010] Refer to accompanying drawing 1. The present invention comprises an inner pipe 1 and an outer pipe 2 bonded with the inner pipe, the outer pipe is provided with a reinforced bonding layer 3 wrapped around the composite pipe by glass fiber cloth, and the reinforced bonding layer is combined with multiple impregnated The glass fiber strands 4 of resin solidify into the outer tube 2 .

[0011] In this embodiment, the bonding layer is one layer, located on the inner wall surface of the outer tube.

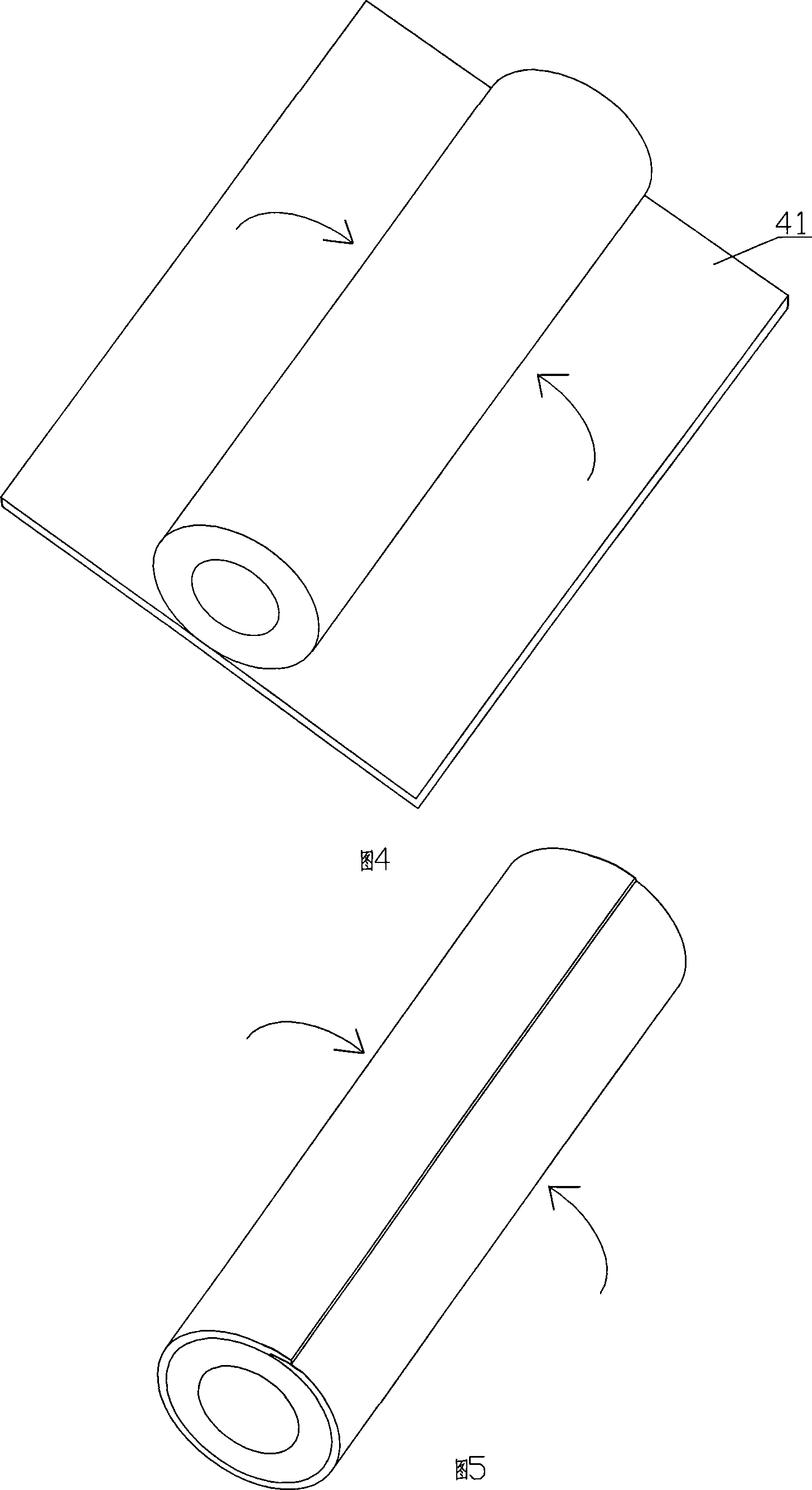

[0012] The inner tube can be made of tissue paper soaked in zinc chloride, wound in multiple layers and treated after heating, and the outer tube can be formed by drawing glass fiber yarn 4 and glass fiber cloth at one time. The direction of glass fiber yarn 4 is the same as The axes of the inner tubes are consistent. In practice, the glass fiber density of the glass fiber cloth oriented in the axial direction of the composite pipe can be greater than the density of glass fibe...

Embodiment 2

[0015] Refer to accompanying drawing 2. This embodiment is basically the same as Embodiment 1, except that the reinforcing bonding layer is in the outer tube wall.

[0016] In FIG. 2 , the reference numerals are the same as those in FIG. 1 and have the same meanings.

Embodiment 3

[0018] Refer to accompanying drawing 3. The present invention comprises an inner pipe 31 and an outer pipe 32 bonded with the inner pipe, the outer pipe is provided with a reinforced bonding layer wrapped by glass fiber cloth along the circumference of the composite pipe, and the reinforced bonding layer is combined with multiple strands of impregnated resin The glass fiber filaments 34 solidify into the outer tube 32.

[0019] In this embodiment, there are 2 reinforced bonding layers, respectively denoted by 33a and 33b, and the reinforced bonding layers are located on the inner wall surface of the outer tube and in the outer tube wall. In addition, according to the different wall thicknesses of the outer tube, one or more reinforced bonding layers may be added in the outer tube.

[0020] In practice, the seams of the reinforced bonding layers of adjacent layers are preferably staggered, which can further enhance thermal expansion and contraction resistance and torsion resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com