Wheel boss motor power wheel

An in-wheel motor and wheel technology, applied in electric vehicles, electric power devices, motors, etc., can solve the problem that the volume of high-power motors cannot be directly installed on the vehicle chassis, hindering the rapid development, progress and popularization of electric vehicles, low-power Insufficient output torque of the motor, etc., to achieve the effect of facilitating the mechanization of the assembly line, saving on-board power, and simple processing and assembly methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

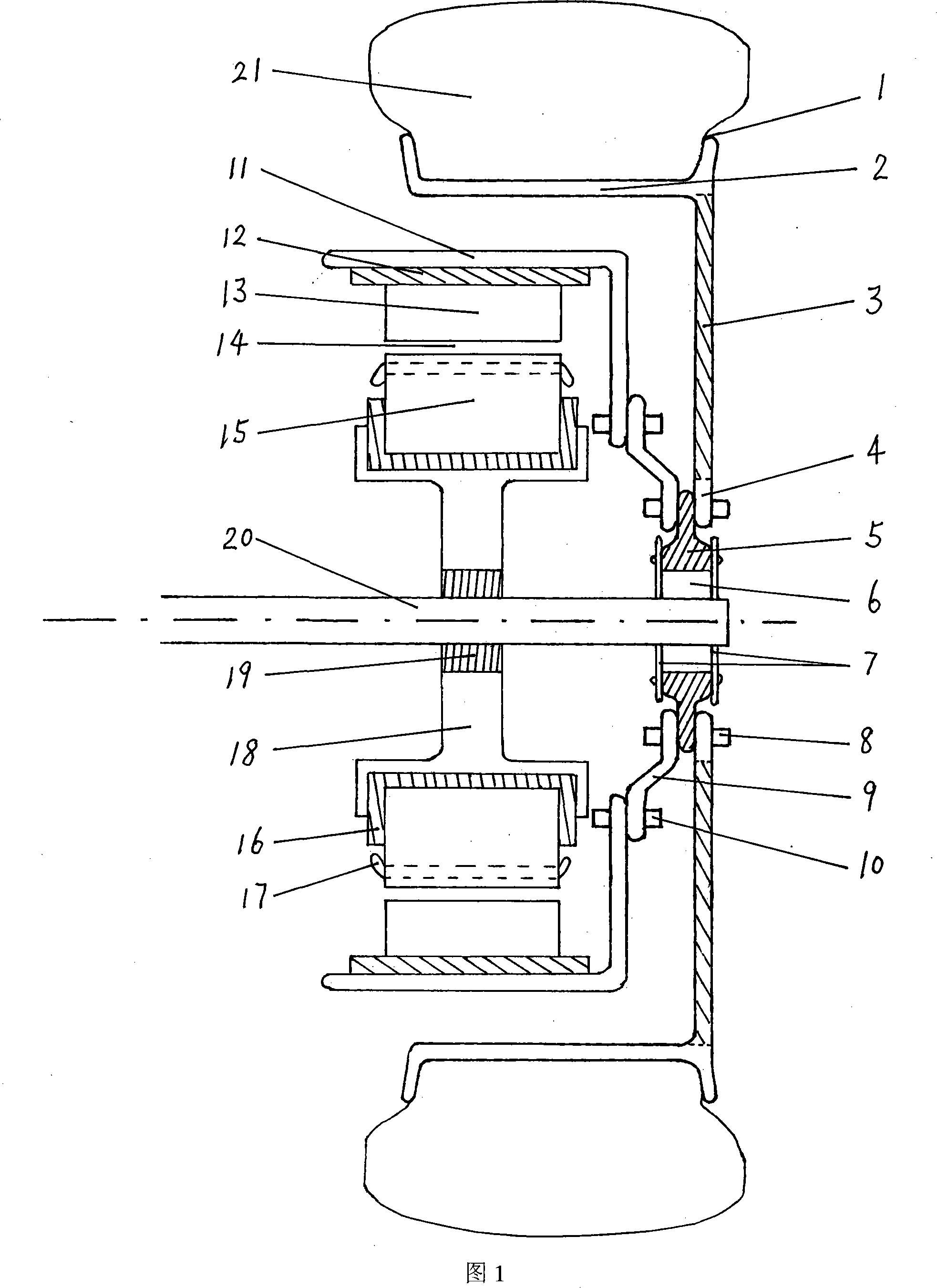

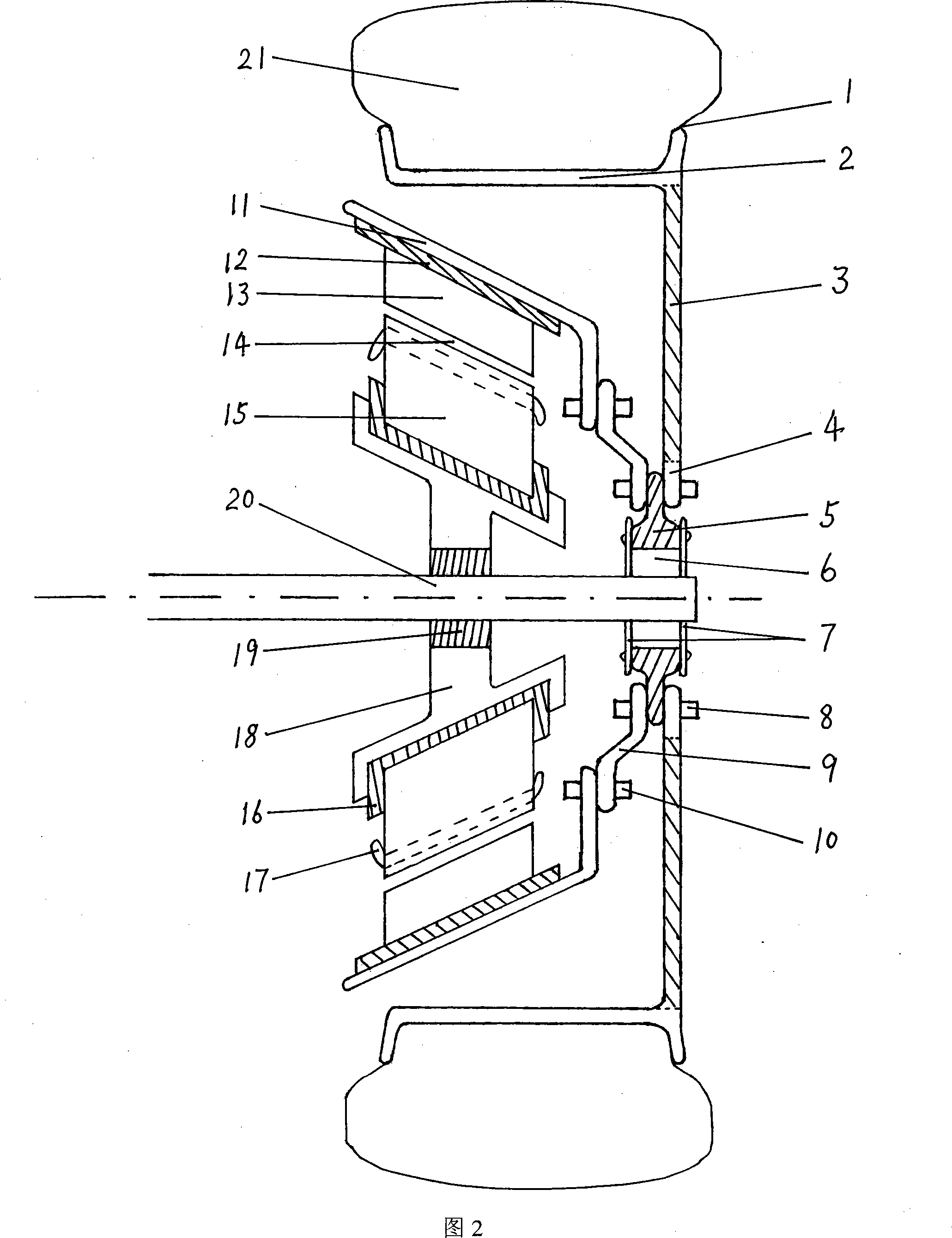

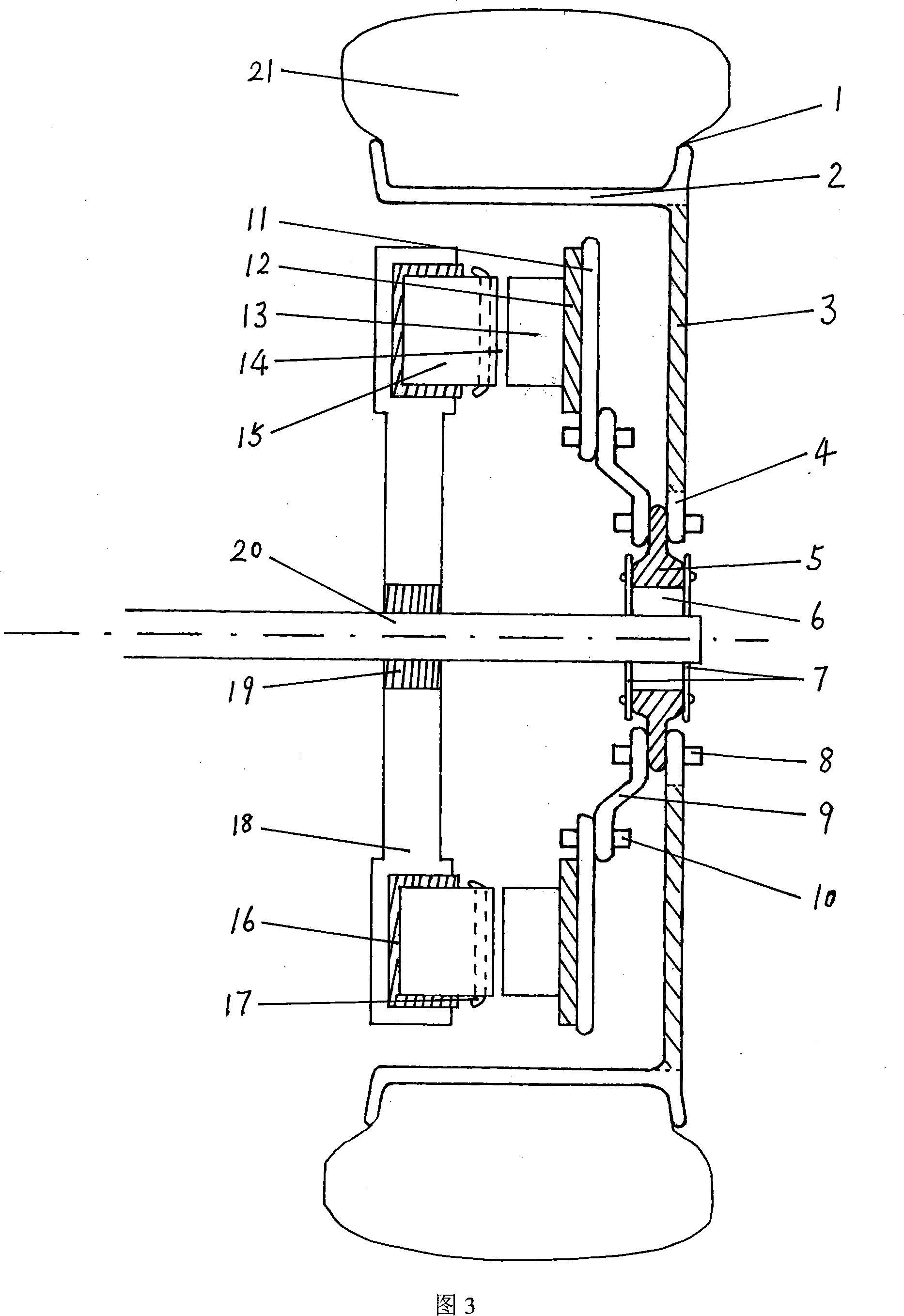

[0020] Below again in conjunction with accompanying drawing, the specific embodiment of the application of the present invention is described in further detail:

[0021] Shown in accompanying drawing 1, be an embodiment of the application of the present invention. In the power wheel shown in FIG. 1 , the three mechanical parts of the bearing support connecting plate 5 tightly sleeved outside the bearing 6 on the axle 20 , the wheel hub 4 and the motor rotor bracket 9 are connected and fastened by the hub connecting bolts 8 become a mechanical whole. The motor primary stator 15 is connected and fixed with the axle to form a mechanical whole through the motor stator fastening yoke 16, the motor stator frame 18 and the motor stator frame seat 19. Because the axle is determined to be stationary by other components (such as vehicle frame, suspension, etc.) other than the wheel, the primary stator 15 of the motor is also determined to be stationary together with the axle. When cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com