Motor vehicle filtering silencer

A technology for filtering mufflers and motor vehicles, which is applied in the direction of mufflers, machines/engines, mechanical equipment, etc. It can solve the problems of poor muffler use effect, waste of steel materials, and shortened service life, so as to achieve good use effect and save steel , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

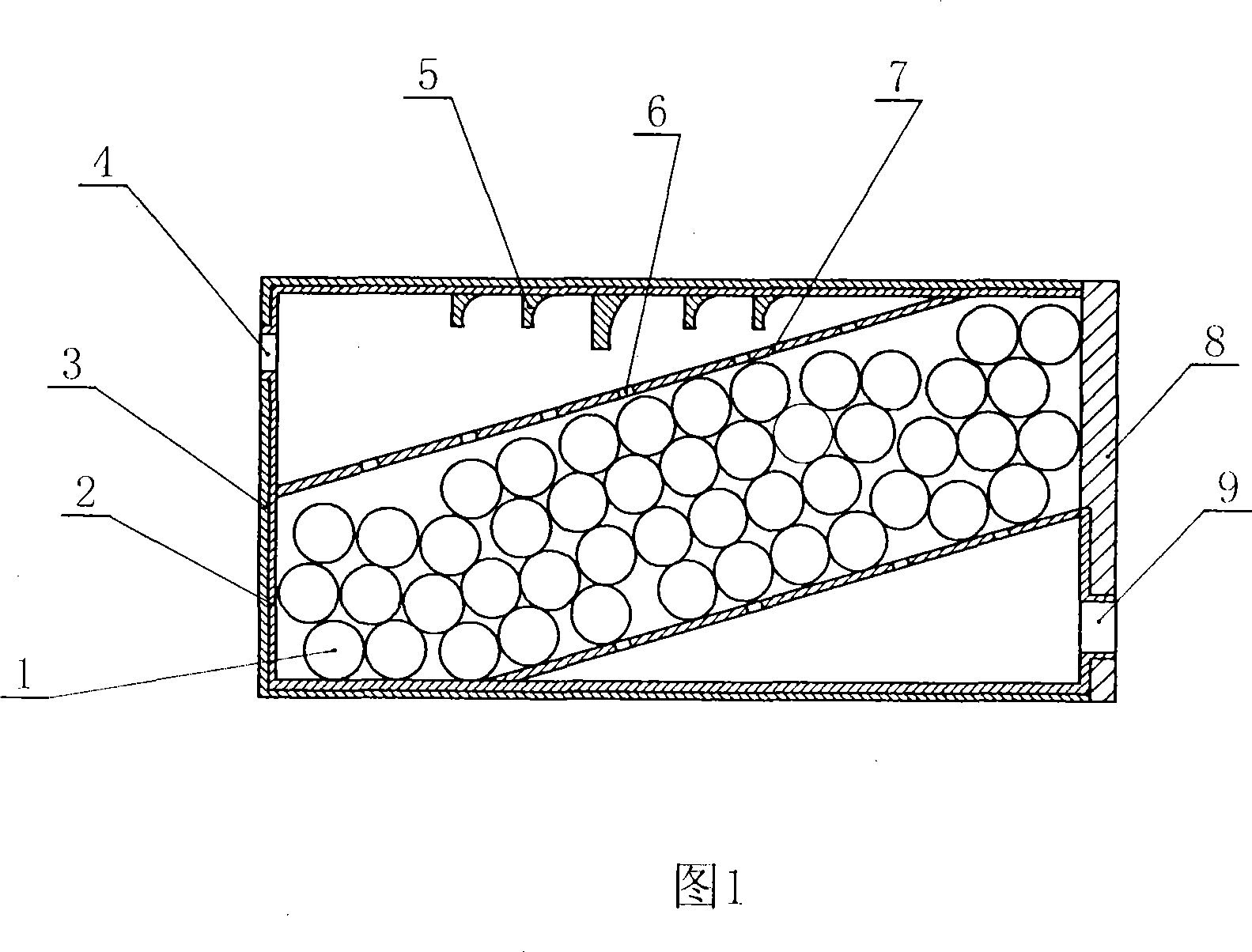

[0010] A filter muffler for a motor vehicle, as shown in Figure 1, which includes a metal shell 3, the left side wall of the metal shell 3 is provided with a shell air inlet, the filter muffler for a motor vehicle also includes a ceramic inner core 2, a metal shell 3 There is a ceramic inner core installation opening to the right; the ceramic inner core installation opening corresponds to the ceramic inner core 2, the ceramic inner core 2 is located in the cavity of the metal shell 3 and is fixedly connected with it, and the left side wall of the ceramic inner core 2 has a The inner core air inlet 4, the inner core air inlet 4 is corresponding to and communicated with the shell air inlet, the ceramic inner core 2 has an inner core air outlet 9 on the right side wall, the inner core air inlet 4, the ceramic inner core 2 cavities and the inner core exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com