Reference current source circuit and infrared signal processing circuit

一种基准电流源、电流源的技术,应用在电子电路测试、非电信号传输系统、电路等方向,能够解决电路元件数增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0040] One embodiment of the present invention will be described below based on FIGS. 1 and 2 .

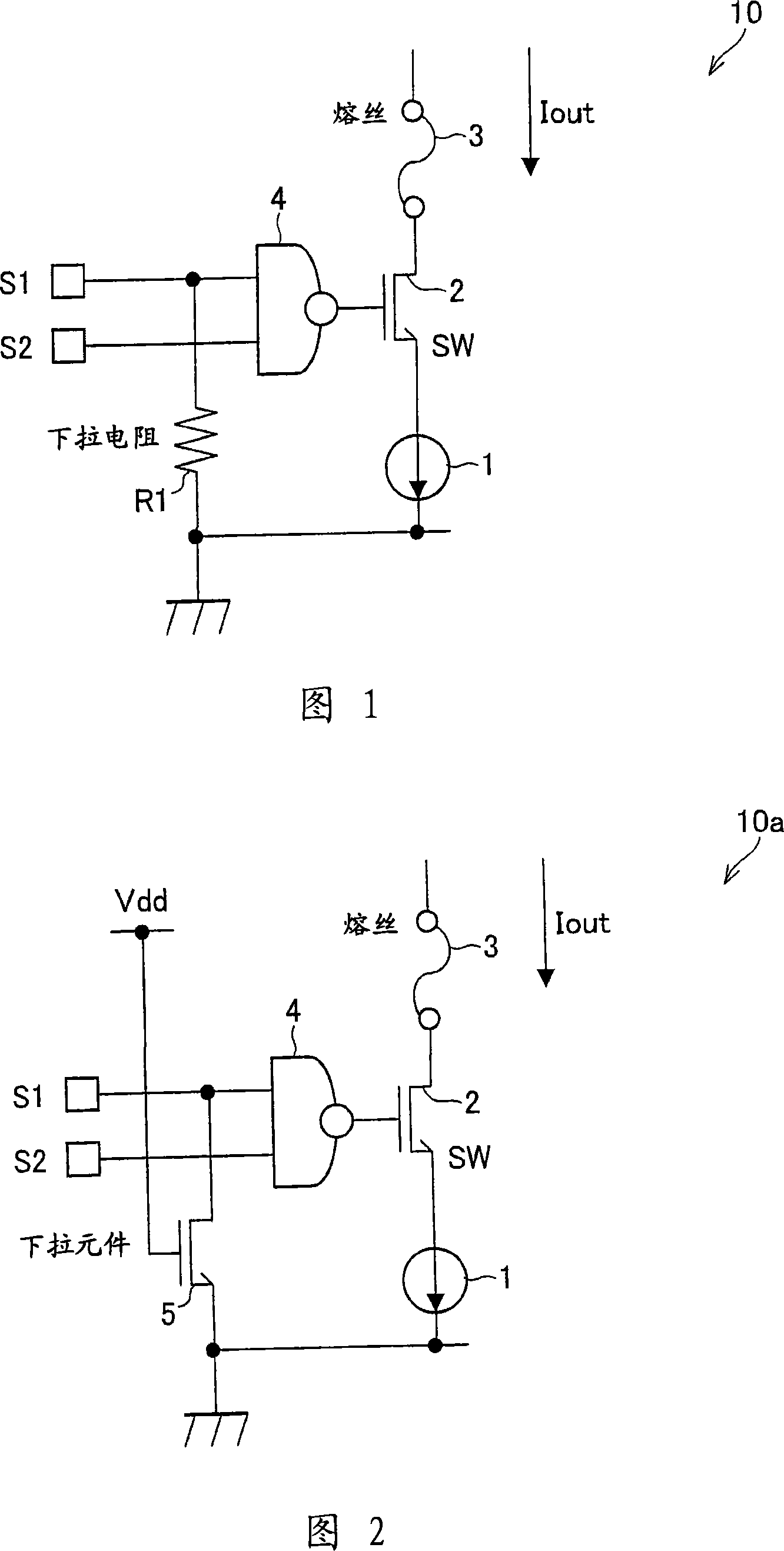

[0041] FIG. 1 shows the configuration of a reference current source circuit 10 for adjusting the characteristics of a semiconductor integrated circuit by fuse trimming.

[0042] The reference current source circuit 10 includes: a current source circuit 1; a switch circuit (SW) 2; a fine-tuning fuse (hereinafter simply referred to as a fuse) 3; a "NAND" circuit 4 (control circuit); and a pull-down resistor R1 (resistance sex element).

[0043] The switch circuit 2 has a function of connecting / disconnecting the current source circuit 1 and the fuse 3, and is composed of an N-channel MOS transistor. The drain of the MOS transistor is connected to an internal circuit of a semiconductor integrated circuit (not shown) through a fuse 3 , and the source of the MOS transistor is connected to a GND terminal through a current source circuit 1 . In addition, the gate of the above-mentioned ...

Embodiment approach 2

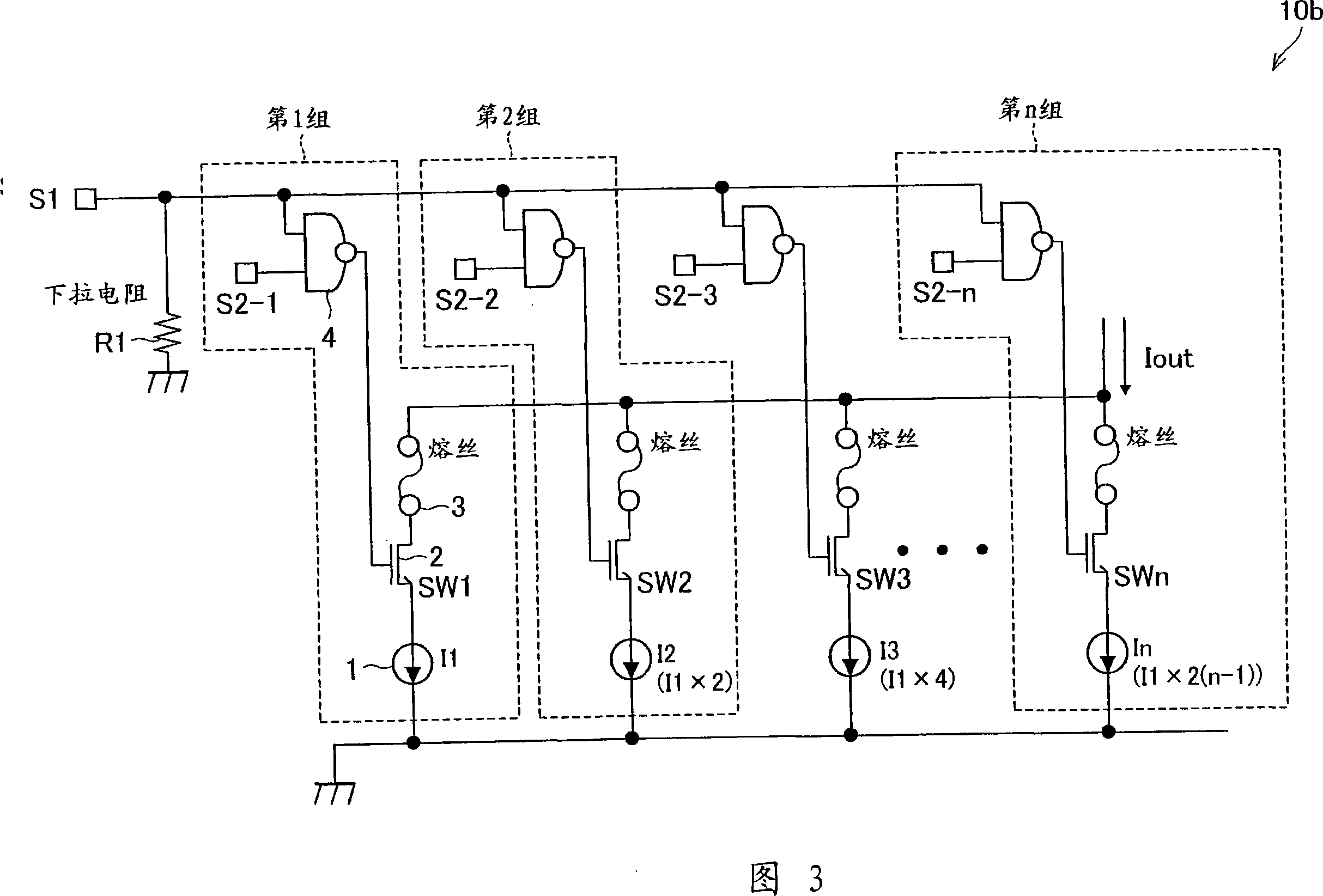

[0053] Another embodiment of the present invention will be described below based on FIG. 2 . Note that components, signals, and the like assigned the same reference numerals as those used in Embodiment 1 above have the same functions, and descriptions are not changed. In addition, here, only the points different from the reference current source circuit 10 will be described.

[0054] FIG. 2 shows a configuration of a reference current source circuit 10a for adjusting the characteristics of a semiconductor integrated circuit by fuse trimming.

[0055] The reference current source circuit 10a differs from the reference current source circuit 10 in that a pull-down element (resistive element) 5 is included instead of the pull-down resistor R1. Pull-down element 5 is composed of an N-channel type MOS transistor. The drain of the MOS transistor is connected to one input terminal of the NAND circuit 4 , the source is connected to the GND terminal, and the gate is connected to the ...

Embodiment approach 3

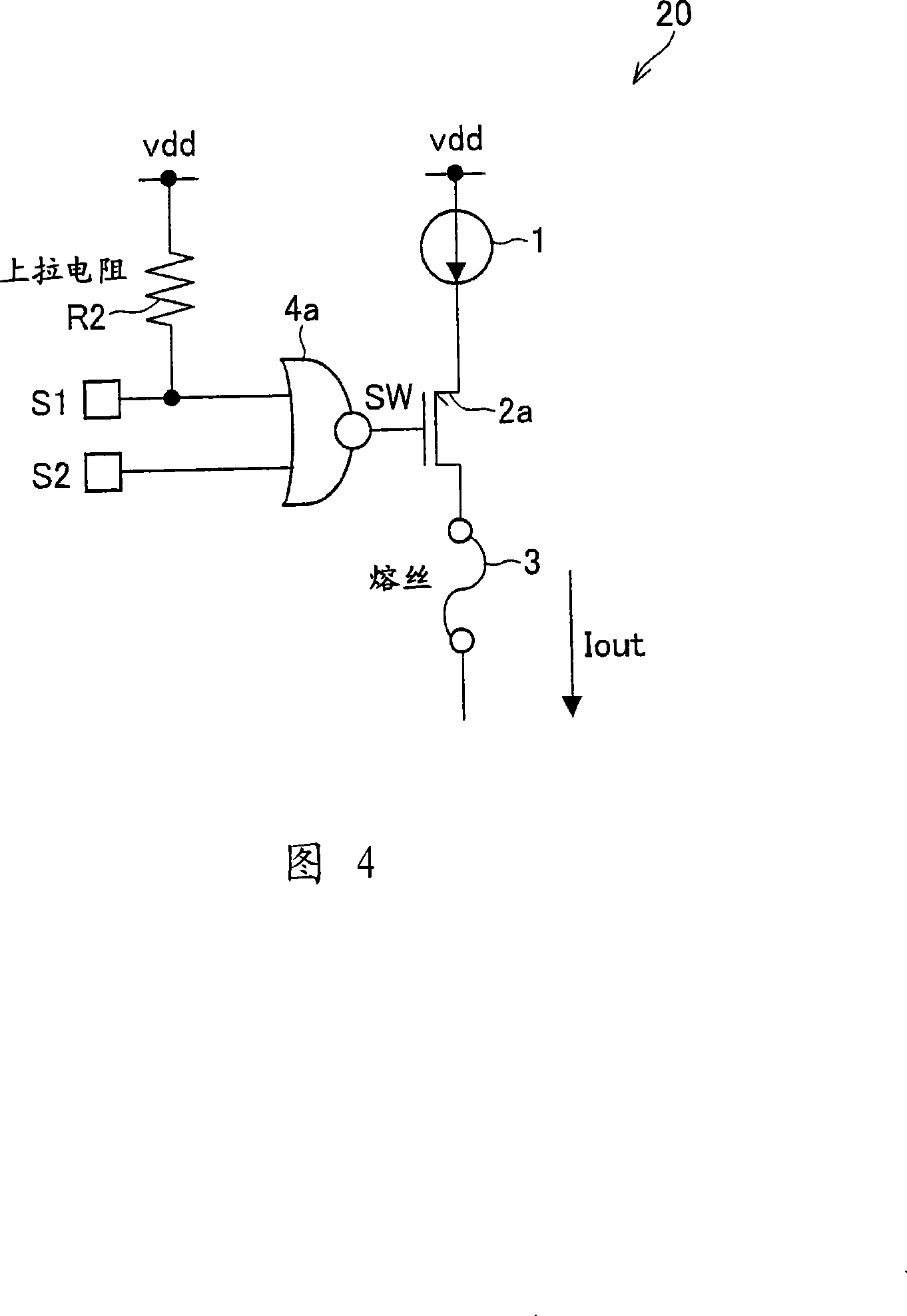

[0058] Another embodiment of the present invention is described below based on FIG. 3 and Table 3. Note that components, signals, and the like assigned the same reference numerals as those used in Embodiment 1 above have the same functions, and descriptions are not changed.

[0059] FIG. 3 shows a configuration of a reference current source circuit 10b for adjusting the characteristics of a semiconductor integrated circuit by fuse trimming.

[0060] The reference current source circuit 10b has the following structure: when the current source circuit 1, the switch circuit 2, the fuse 3 and the "NAND" circuit 4 in the reference current source circuit 10 are regarded as a group (set), it includes n This group of levels. One input terminal of each NAND circuit 4 in the n-stage group is connected to each other and shared, and the control signal S1 is input thereto. The control signal S2 (S2-1 to S2-n) is input to the other input terminal of each NAND circuit 4, respectively. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com