Soft PLC module of open type soft numerical control system

A numerical control system and an open technology, applied in the field of PLC modules, can solve the problems of high price, poor versatility and compatibility, and achieve the effect of low cost, good versatility and compatibility, and full use of hardware resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

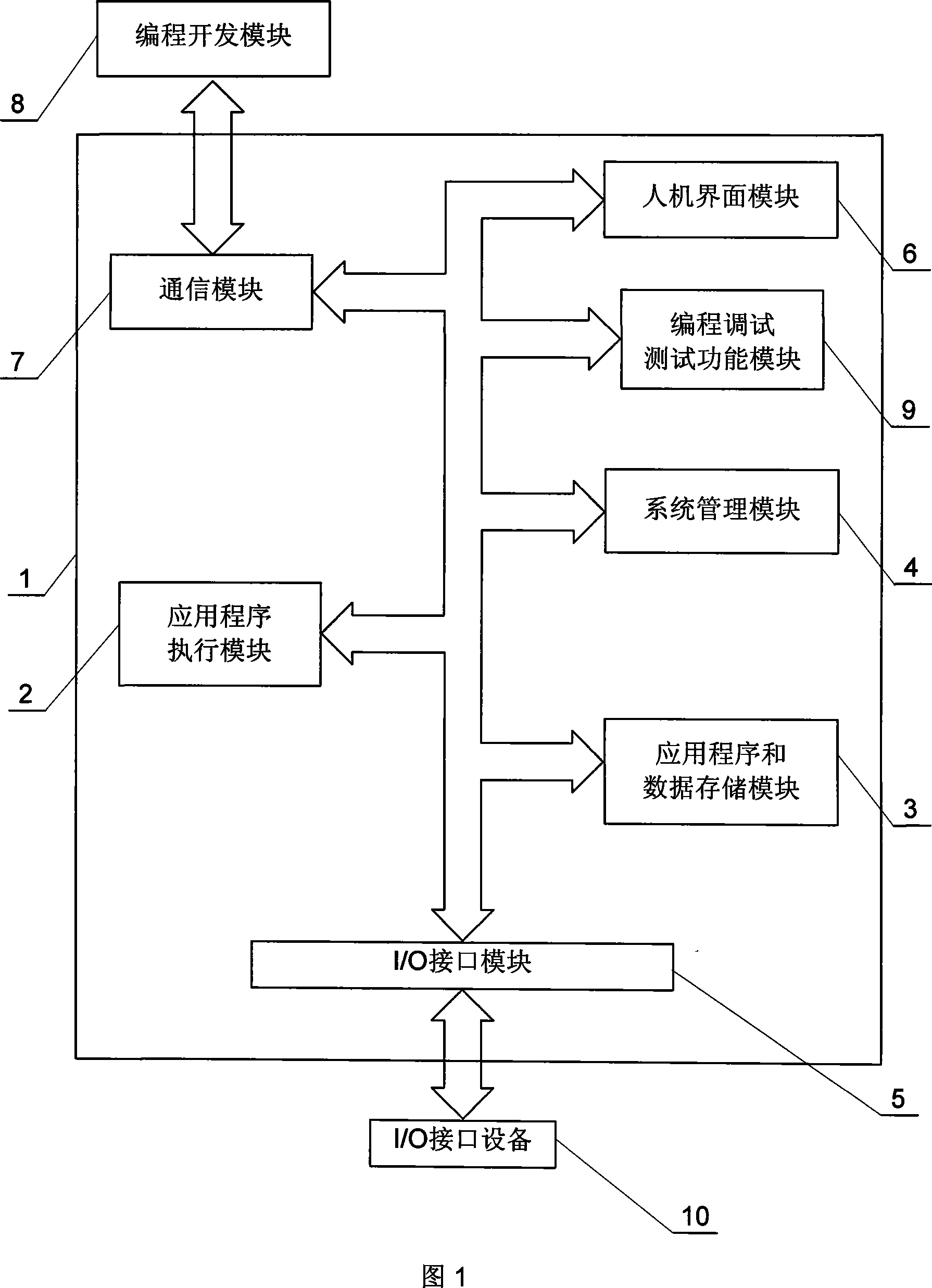

[0012] Specific embodiment one: referring to Fig. 1, this embodiment is made up of the following units:

[0013] The application program execution module 2 reads the corresponding instructions from the application program and the data storage module 3, and the instruction calls the PLC program in the memory to perform the corresponding task to complete the logic control and motion control functions required by the user, and the execution result of the PLC program It is transmitted to the I / O interface device 10 through the I / O interface module 5, and the execution result is displayed on the man-machine interface module 6. In the scheduling process, the organization form of multi-task is adopted, and the next step is determined according to the execution state information of the current program. or multiple parallel task runs;

[0014] The application program and data storage module 3 is used to apply for a section of memory in the memory as the memory space for PLC program exe...

specific Embodiment approach 2

[0020] Specific embodiment two, referring to Fig. 1, present embodiment has increased following unit on the basis of specific embodiment one: system management module 4, set system parameter, set up system by man-machine interface module 6 before running each PLC program environment, within the scan period of the PLC program, dispatch system multitasking threads through the man-machine interface module 6, monitor the running status of the PLC program, and respond in time according to user operations. The system creates an event object for each task thread to coordinate the execution of multi-task threads. As long as the event is not triggered, the thread is in a sleep state. Use the RtWaitForSingleObjects() or RtWaitForSingleMultiObjects() primitive in the task thread to wait for the trigger of the synchronization object. System management Module 4 manages the task thread to determine one or more parallel running tasks according to the current program execution status word info...

specific Embodiment approach 3

[0021] Specific embodiment three, referring to Fig. 1, this embodiment adds the following unit on the basis of specific embodiment one: programming debugging test function module 9, provides the function that the user is programmed and debugged to the system, and can pass the third party's programming system to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com