Composite insulator and manufacturing method thereof

A technology of composite insulators and sheds, applied in the high-voltage field, can solve the problems of moisture on the outer insulating surface, unfavorable water droplet aggregation and rolling, partial discharge, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

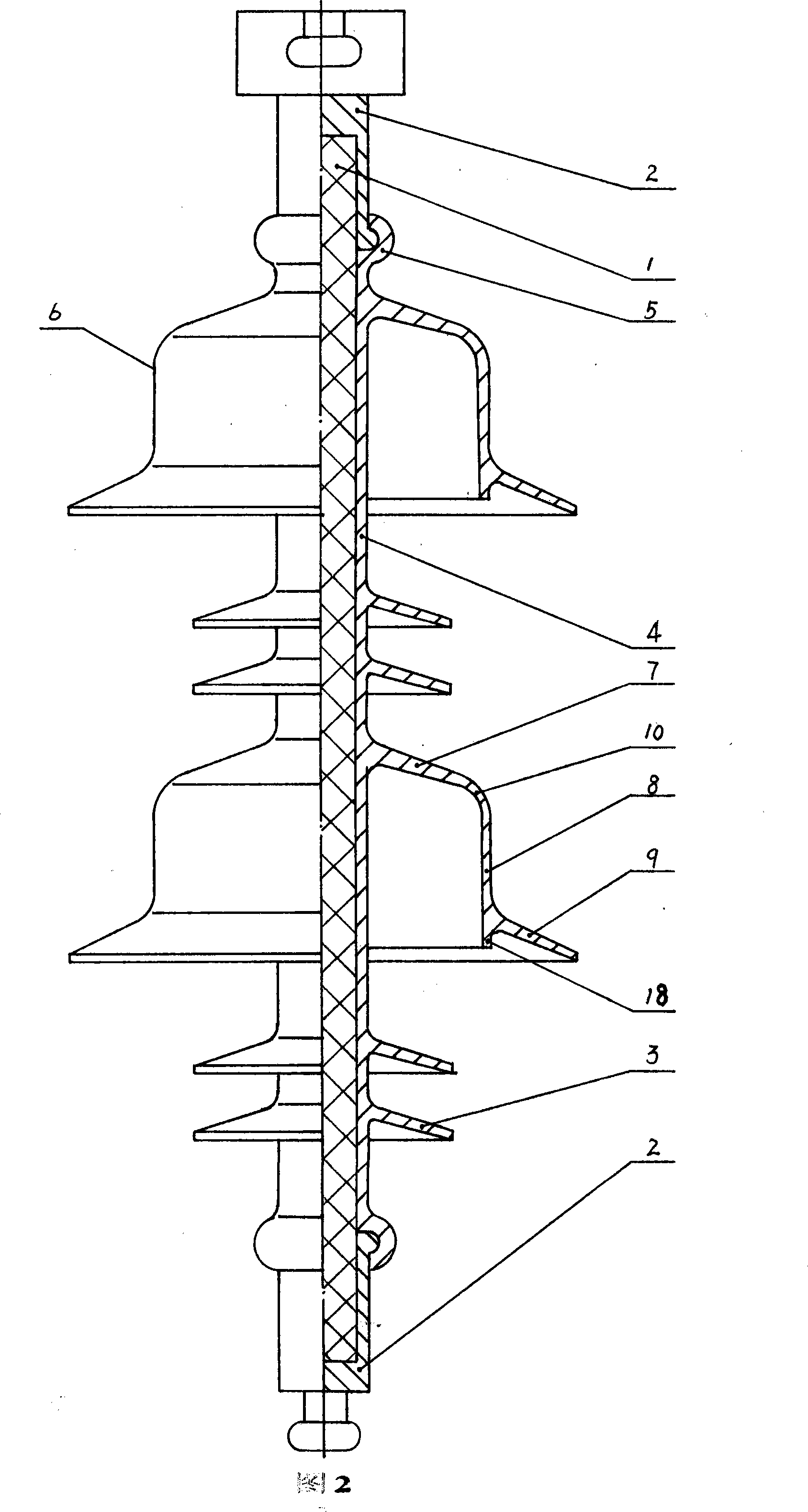

[0027] Fig. 2 is a half-sectional view of a composite insulator of the present invention. The umbrella structure of the composite insulator is composed of two shed groups connected in series under a hooded shed and 2 ordinary sheds in series. After extending outward at an inclination angle of 85° to form an upper slope, it extends downward at an inclination angle of 85° to form a vertical surface, and then extends outward at an inclination angle of 30° to form a lower slope. The flow pair of sheds forms a hat-like shed, and the upper slope and the vertical surface form a hollow-shaped shed with a height of about 50 mm. The diameter of the bottom of the flow shed.

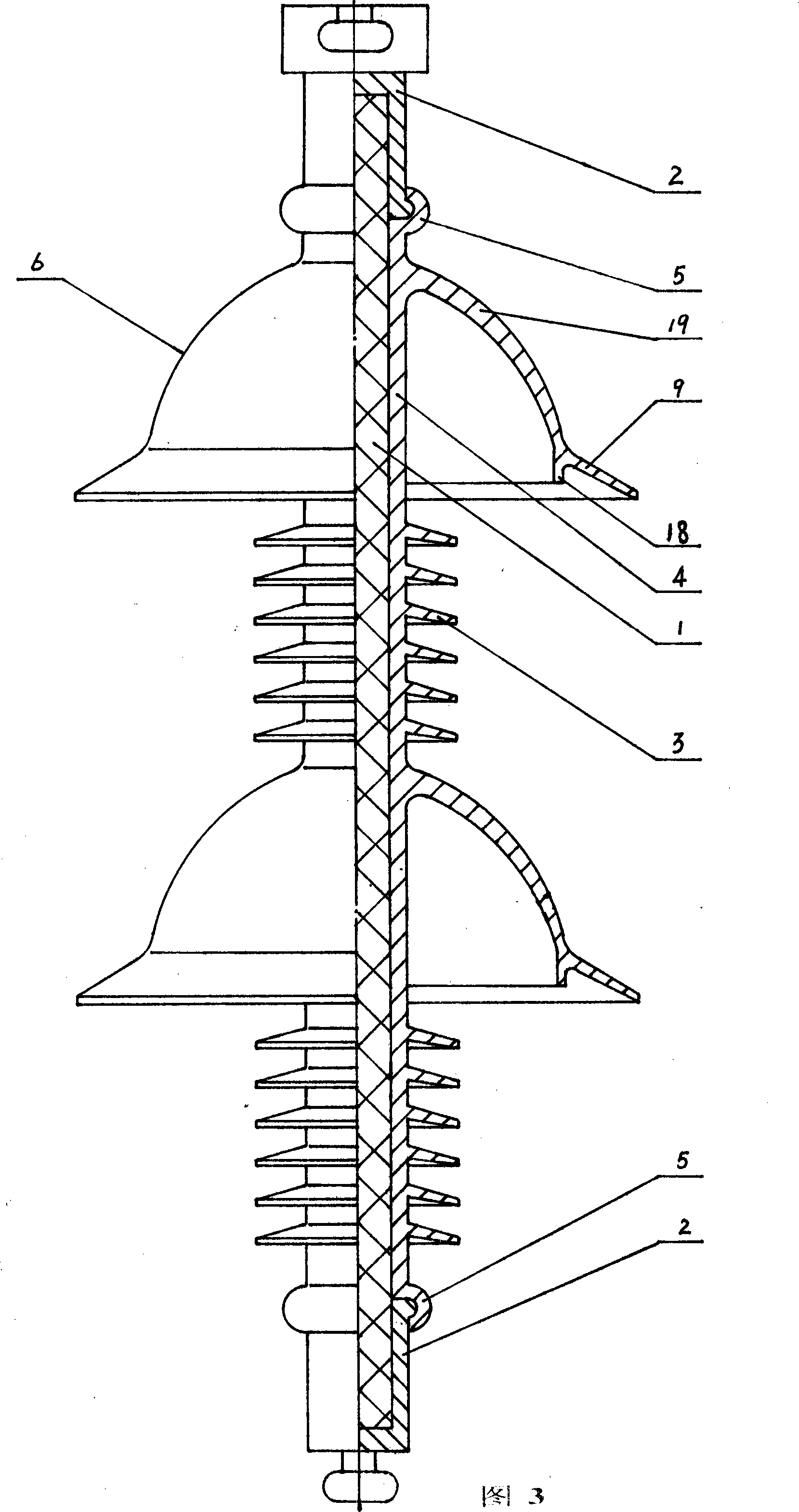

[0028] Fig. 3 is a half-sectional view of a composite insulator of the present invention. The umbrella structure of the composite insulator is composed of two shed groups connected in series under a hat-like shed and 6 ordinary sheds. The top of the hat-like shed is connected to the sheath in an arc The way exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com