Gravure platemaking roll and process for producing the same

A technology of gravure plate making and manufacturing method, which is applied in the directions of printing plate, printing plate preparation, plating of superimposed layers, etc., to achieve the effect of excellent printing durability and omitting the chrome plating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

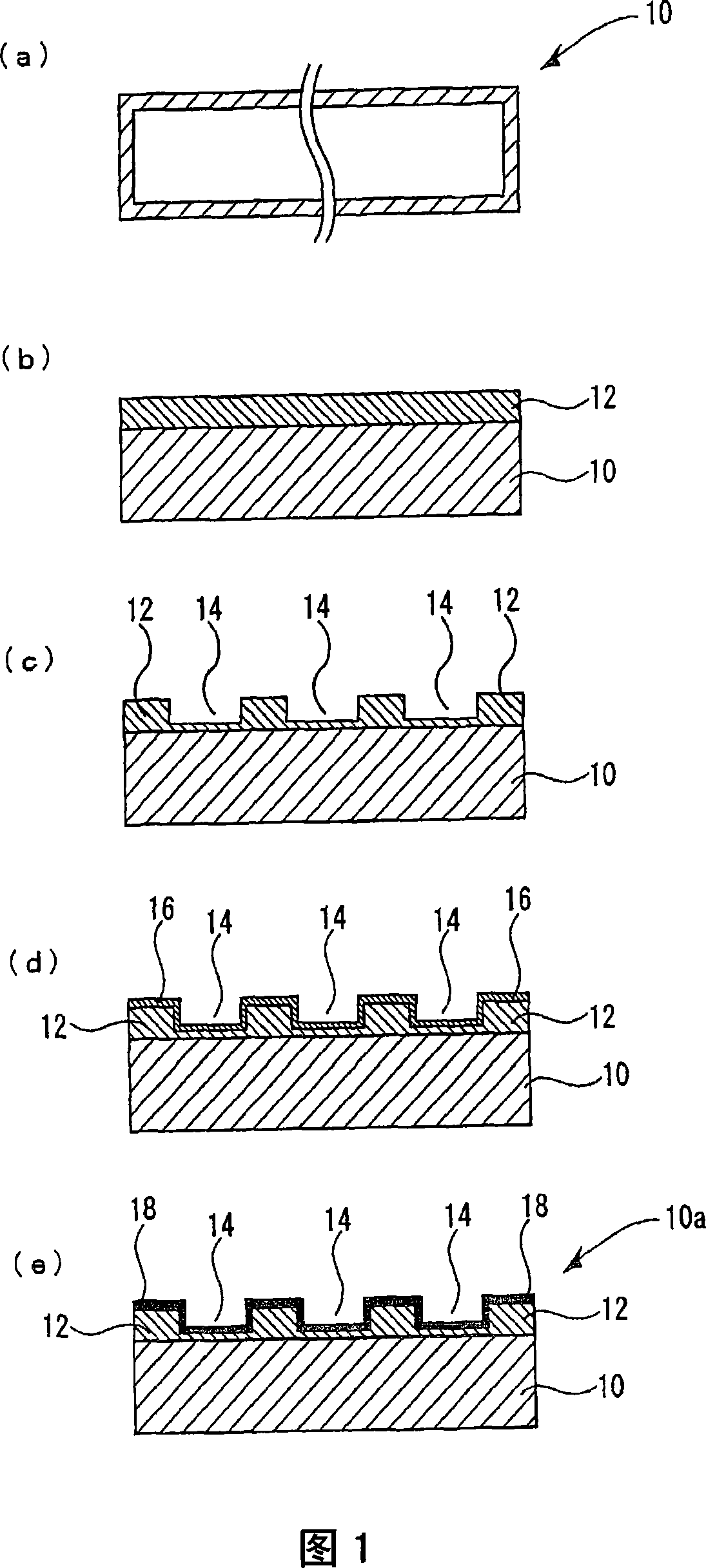

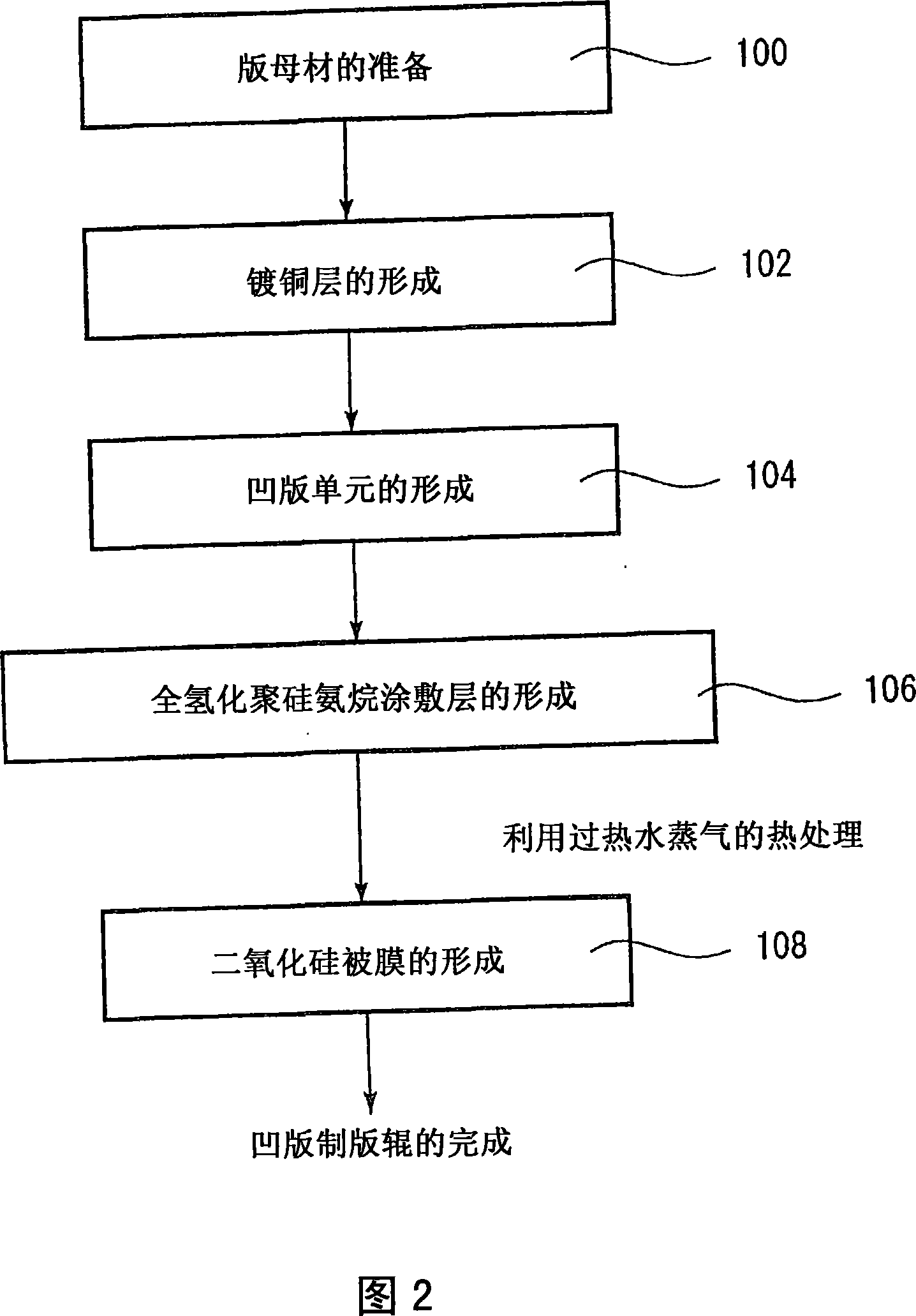

Method used

Image

Examples

Embodiment 1

[0039] Using Boumelan Lain (a gravure roll manufacturing apparatus manufactured by THINK LABORATORY Co., Ltd.), the following copper plating layer formation and etching treatment were performed. First, install a gravure cylinder (aluminum hollow roll) with a circumference of 600 mm and a surface length of 1100 mm in the coating tank, and use an automatic sliding device based on a computer system to make the anode chamber close to the hollow roll until it reaches 20 mm, so that the coating solution is filled. Make the hollow roller fully submerged, at 18A / dm 2 , 6.0V to form a copper plating layer of 80μm. The plating time was 20 minutes, no pits or pits occurred on the plating surface, and a uniform copper plating layer was obtained. Using a 4H grinder (a grinder manufactured by THINK LABORATORY Co., Ltd.), it was ground for 12 minutes to make the surface of the copper plating layer a uniform polished surface.

[0040] A photosensitive film (thermal resist: TSER-2104E4) was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com