Method of improving cabo quality

A tobacco stem and quality technology, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment, can solve the problems that have not been successfully reported, and achieve the effects of reducing tobacco leaf consumption, enhancing oral comfort, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

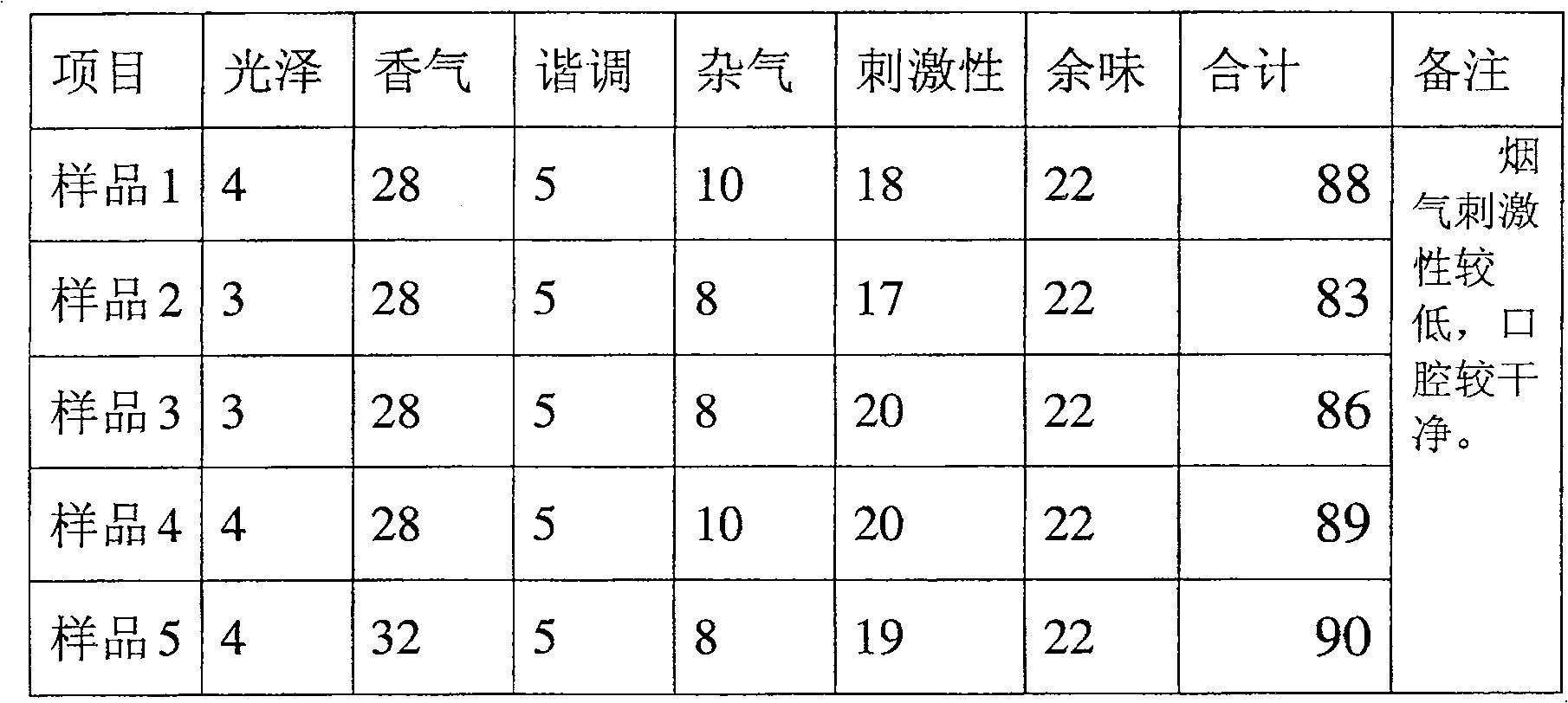

Examples

Embodiment 1

[0026] (1) Take 1g of cellulase and fully dissolve it in 30ml of citric acid solution with a pH value of 5.5 and a concentration of 0.05M;

[0027] (2) Get 5ml of fully dissolved enzyme liquid and evenly spray it on 40g tobacco stems;

[0028] (3) The tobacco stems sprayed with the enzyme liquid are placed for 2 hours at a temperature of 25-45° C. and a humidity of 60-80%;

[0029] (4) Dry at 80°C.

Embodiment 2

[0031] (1) 1 g of hemicellulase is fully dissolved in 30 ml of citric acid solution with a pH value of 5.5 and a concentration of 0.05 M;

[0032] (2) Get 8ml of fully dissolved enzyme liquid and evenly spray it on 40g of expanded stalks;

[0033] (3) The expanded shredded stems sprayed with the enzyme liquid are placed at a temperature of 25-45° C. and a humidity of 60-80% for 4 hours;

[0034] (4) Dry at 80°C.

Embodiment 3

[0036] (1) 1g of hemicellulase and pectinase (ratio 1:1) is fully dissolved in 30ml of citric acid solution with a pH value of 5.5 and a concentration of 0.05M;

[0037] (2) Get 6ml of fully dissolved enzyme liquid and evenly spray it on 40g tobacco stems;

[0038] (3) The tobacco stems sprayed with the enzyme liquid are placed for 3 hours at a temperature of 25-45° C. and a humidity of 60-80%;

[0039] (4) Dry at 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com