High speed purifying and stive zero draining filtrating equipment for tunnel, ship, airplane, car and room

An aircraft and high-speed technology, which is applied in the field of tunnel ship aircraft and indoor high-speed dust purification and zero-emission filter devices, can solve problems such as sales promotion and application that have not yet been seen, and achieve a convenient and rapid popularization and application, stable performance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

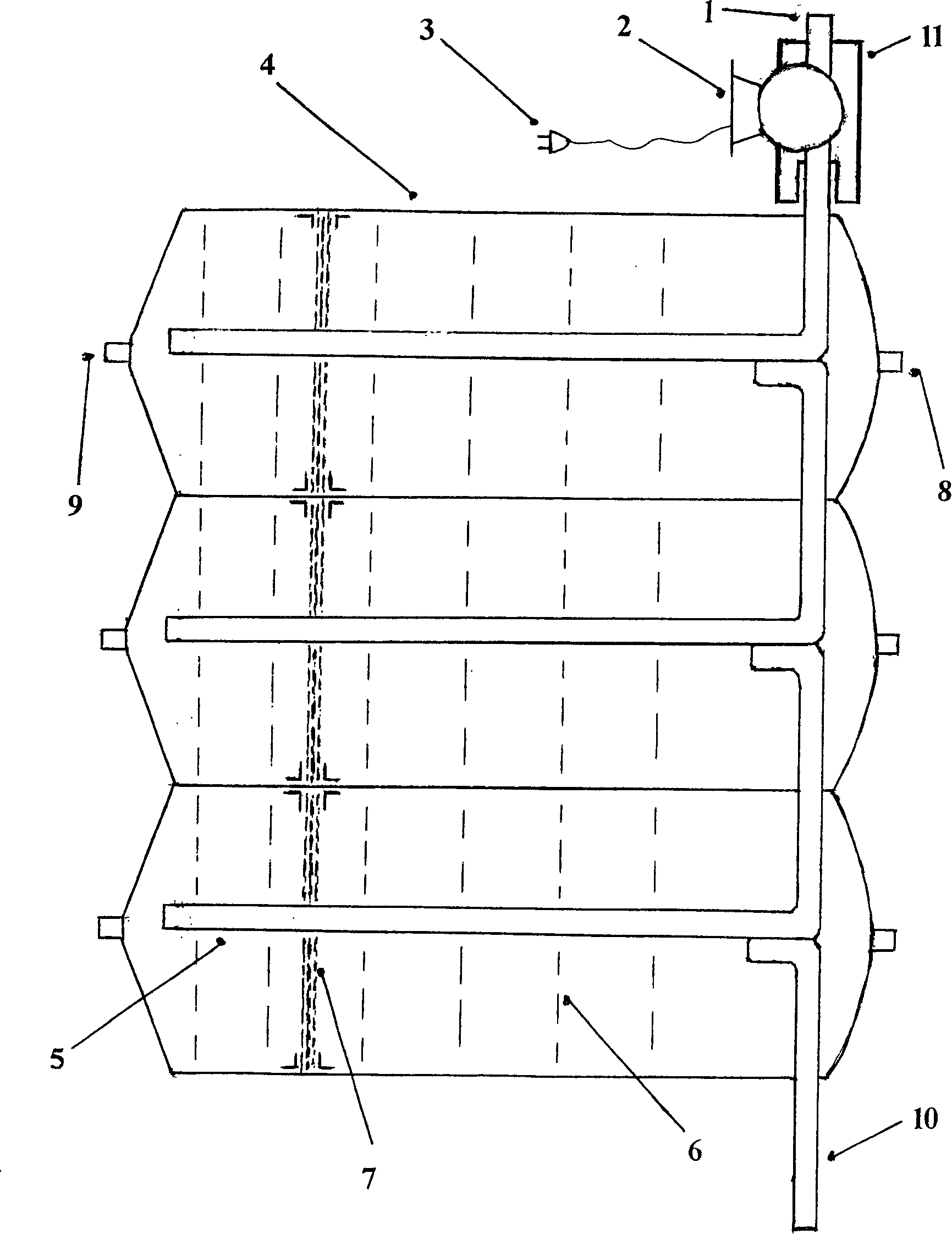

[0009] exist figure 1 In the process, the polluted air and dust enters the pipeline (1) and is connected with the high-pressure high-speed blower (2), the high-pressure high-speed blower (2) is connected with the power supply (3), and the high-pressure high-speed blower (2) is connected with the muffler (11). 4) A connecting gas pipeline (5) is arranged on the top, and the gas pipeline is connected with a high-pressure high-speed blower (2). The tank of the pressure tank (4) is provided with a connecting gas pipeline (5), a gas dust filter liquid (6), and a high-density gas dust filter plate (7). The polluted air and dust enter the pipeline (1), the high-pressure high-speed blower (2), the pressure tank (4), and the gas transmission pipeline (5) are matched and connected to each other. The top of the pressure tank (4) is provided with a connection valve (8), the body of the pressure tank (4) is provided with a gas pipeline (5), and a certain amount of air dust filter is injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com