Cast-in-situs reinforcing wire concrete floor

A reinforced concrete floor slab and reinforced concrete technology, applied in the field of cast-in-place reinforced concrete slabs, can solve the problems of troublesome hollow tube production, high cost, and increased cost of hollow slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

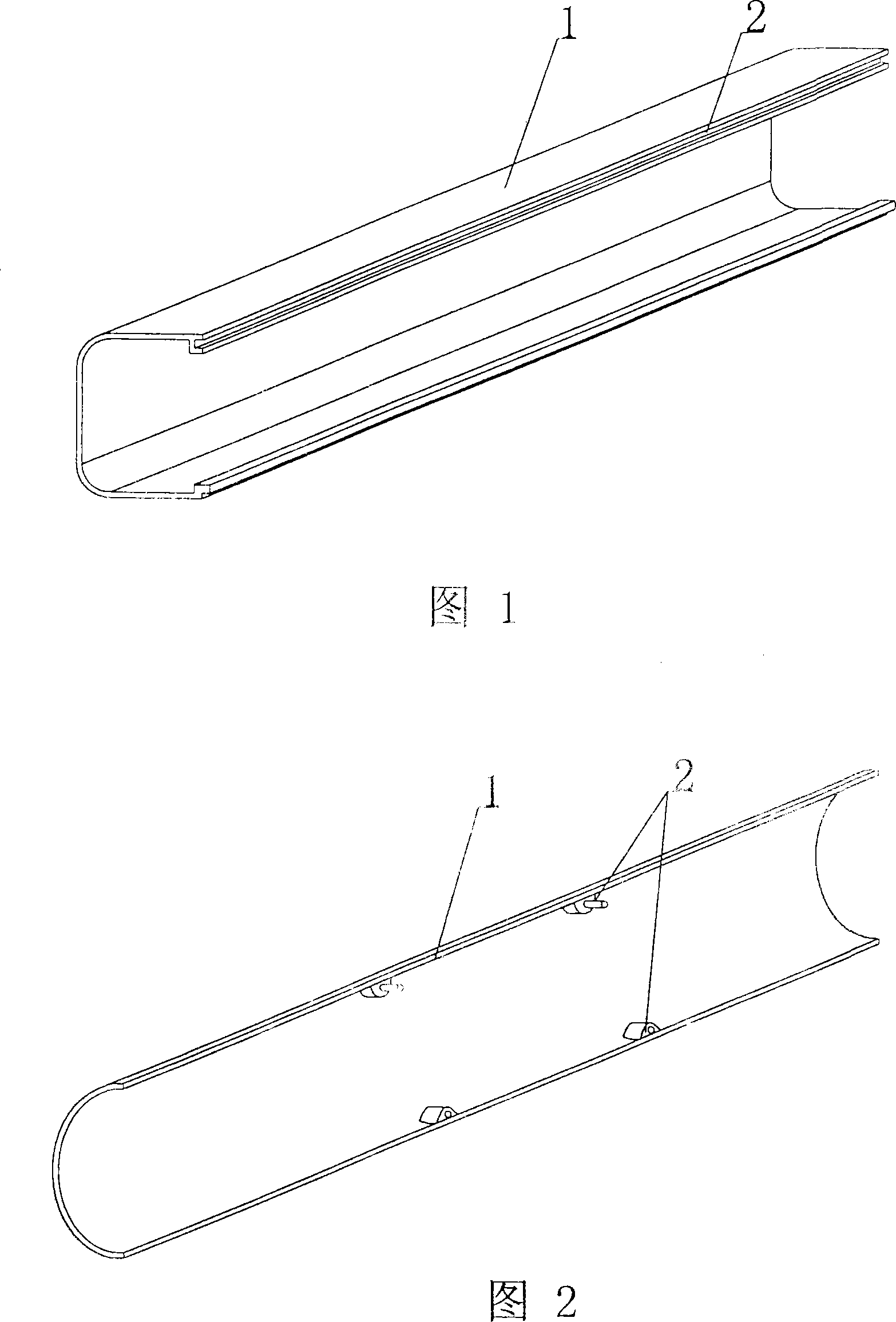

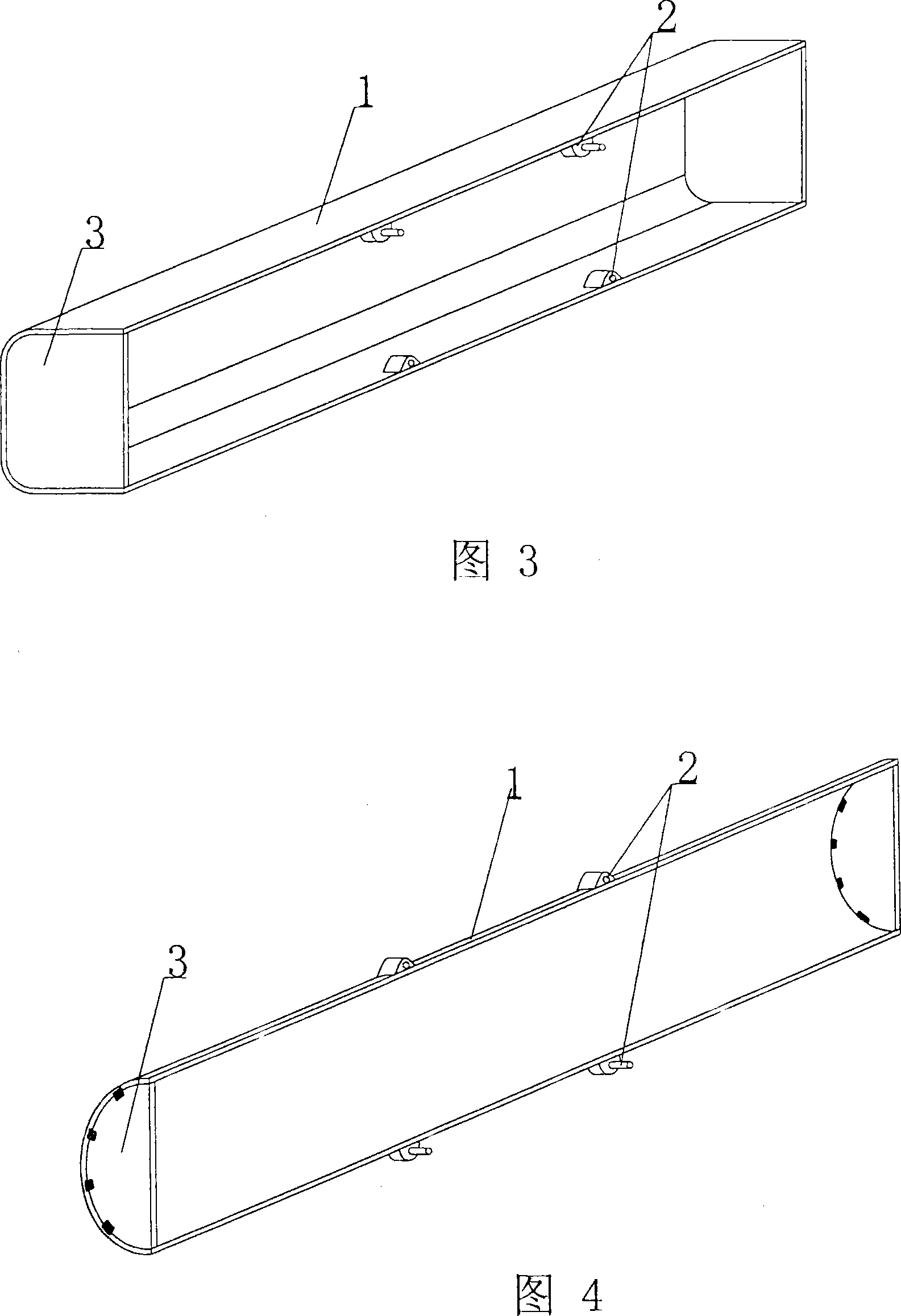

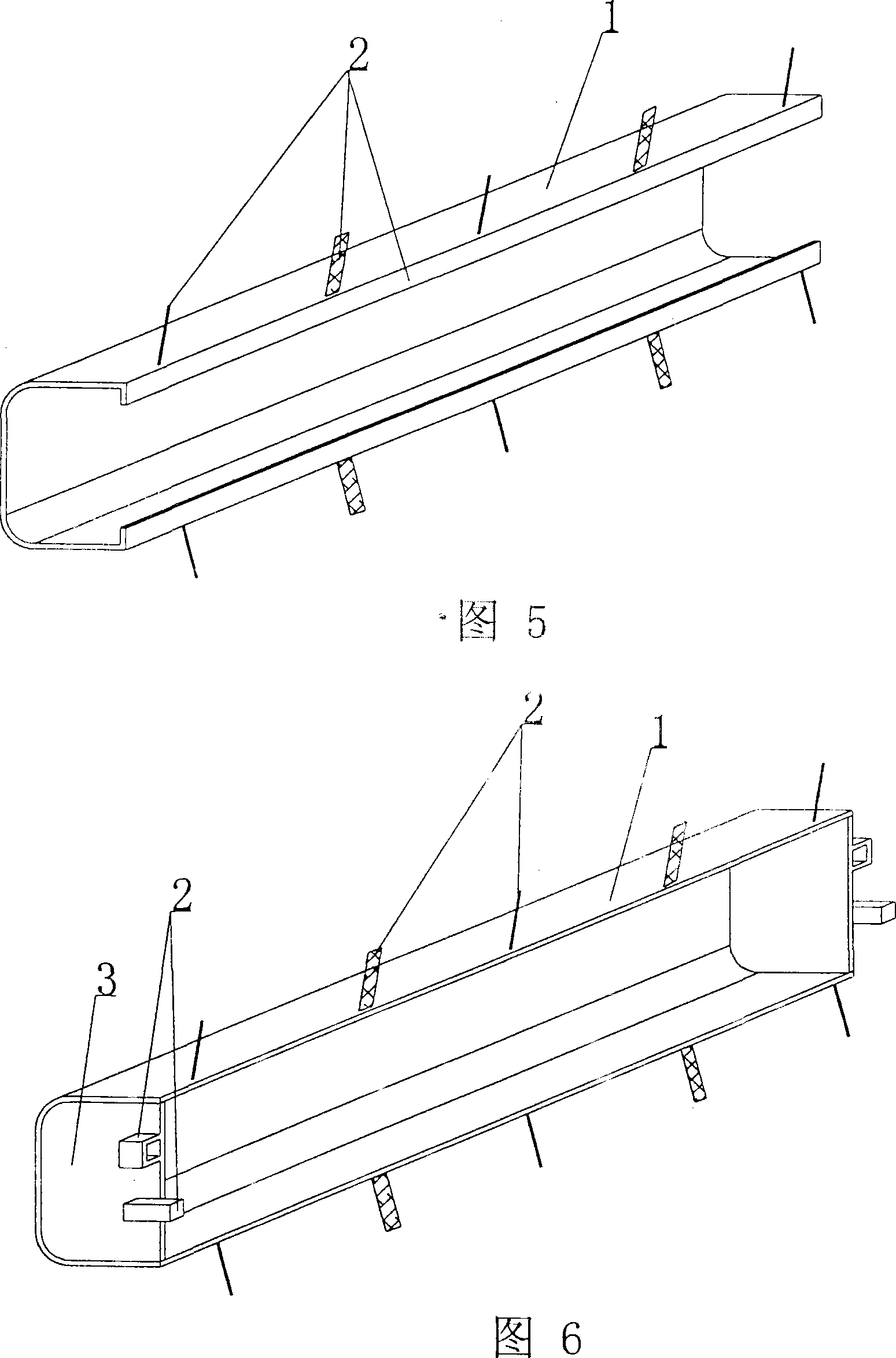

[0037] As shown in the accompanying drawings, the present invention comprises reinforced concrete and a hole-forming member, and is characterized in that the hole-forming member is an integral member composed of a combination part 1 to form a cavity, and the combination part 1 is provided with a connecting piece 2 for combination. The part 1 has a groove 9 and a stiffener 12 in the groove 9 position. In the accompanying drawings, 1 is an assembly part, and 2 is a connecting piece. In each accompanying drawing, those with the same number have the same description. As shown in Figure 1, the hole-forming member is a combination part 1 that constitutes a combined cavity-forming integral part, on which are provided joints 2 for combination, shown as a half-side square-round tubular combination part, and can also be three-pointed. Combination parts in the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com