Liquid crystal display, method for producing liquid crystal display, and electronic apparatus

A technology of a liquid crystal display device and a manufacturing method, which are applied in the directions of static indicators, nonlinear optics, optics, etc., can solve the problems of complicated manufacturing processes and the like, and achieve the effect of high suppression effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

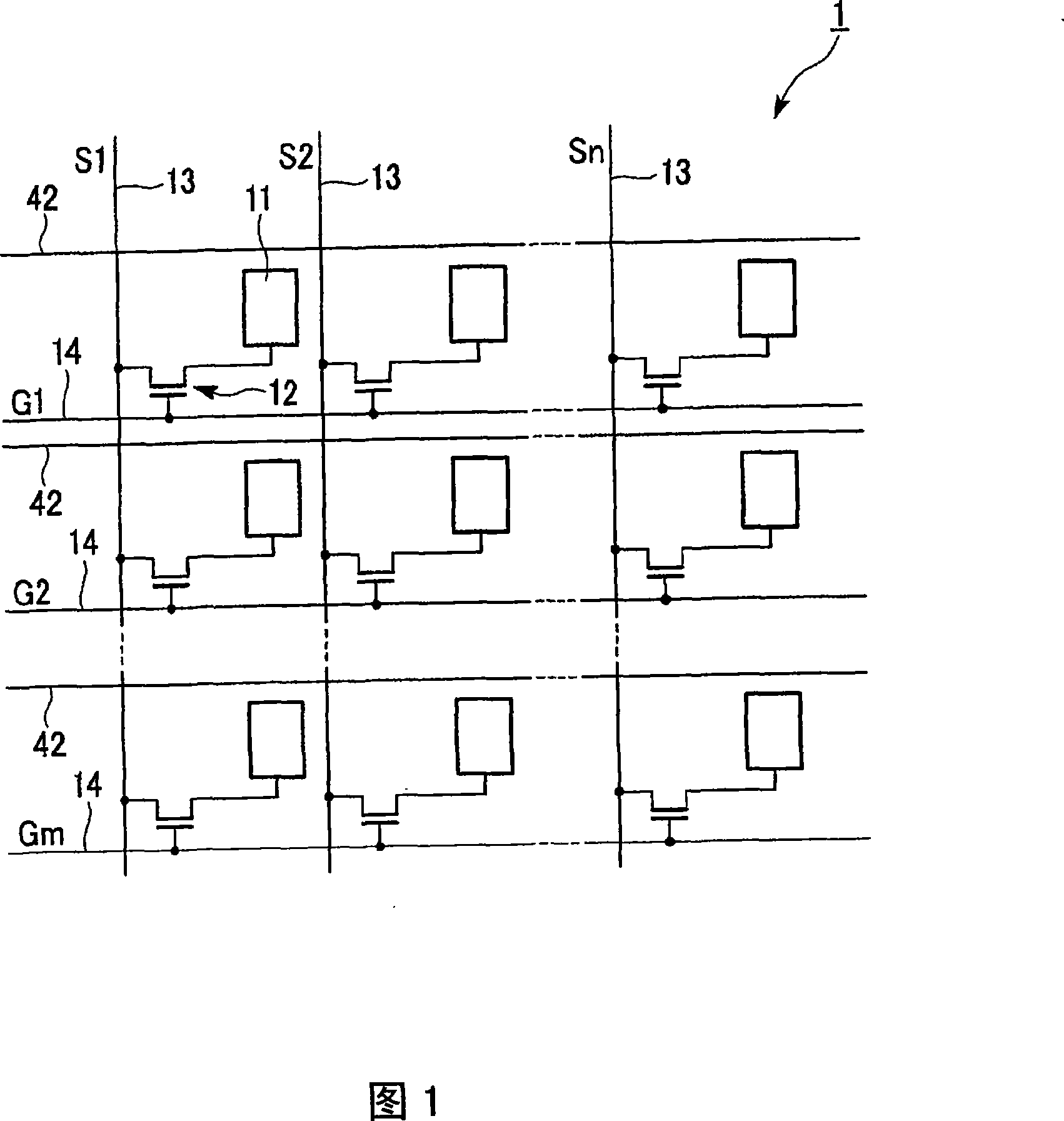

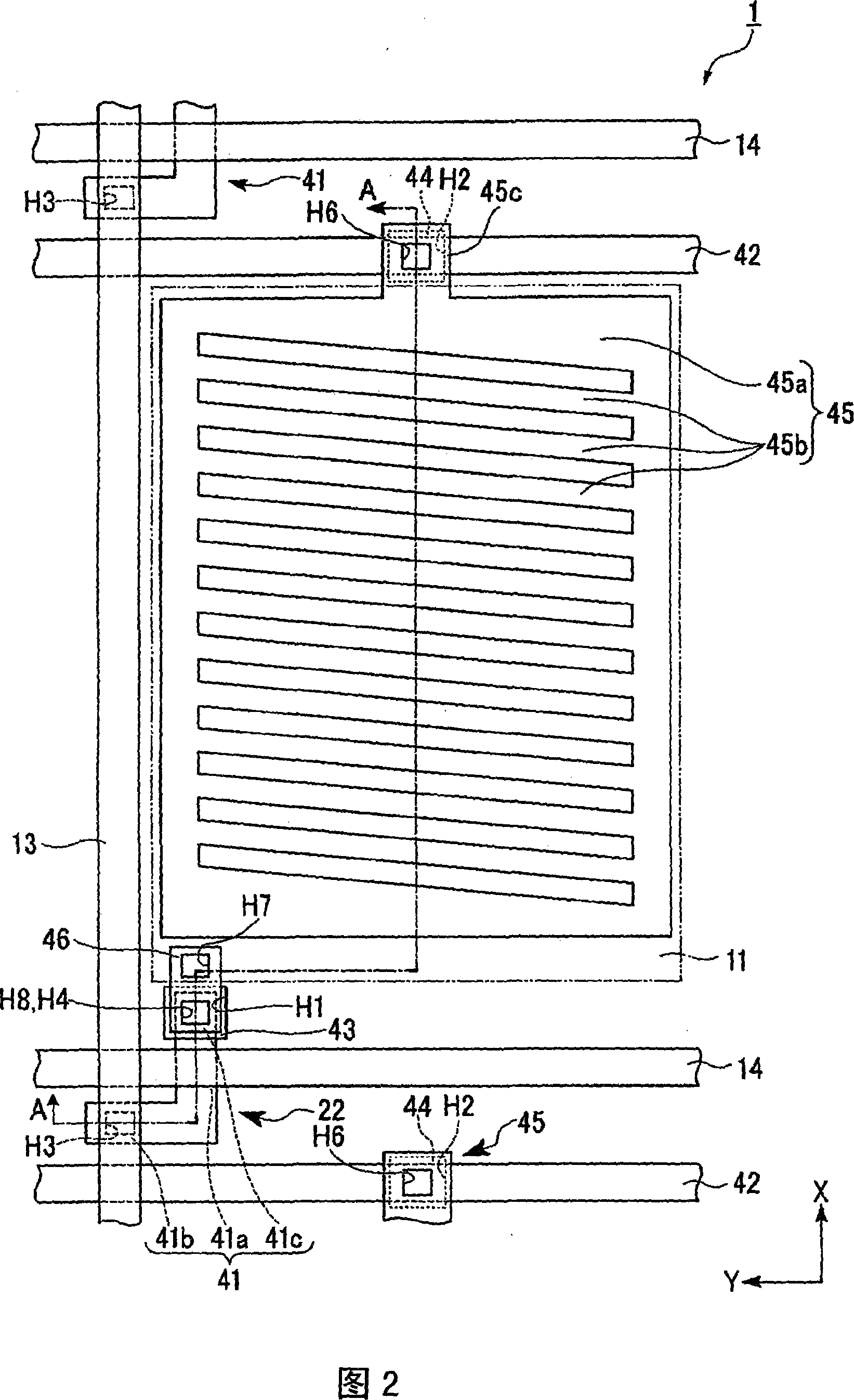

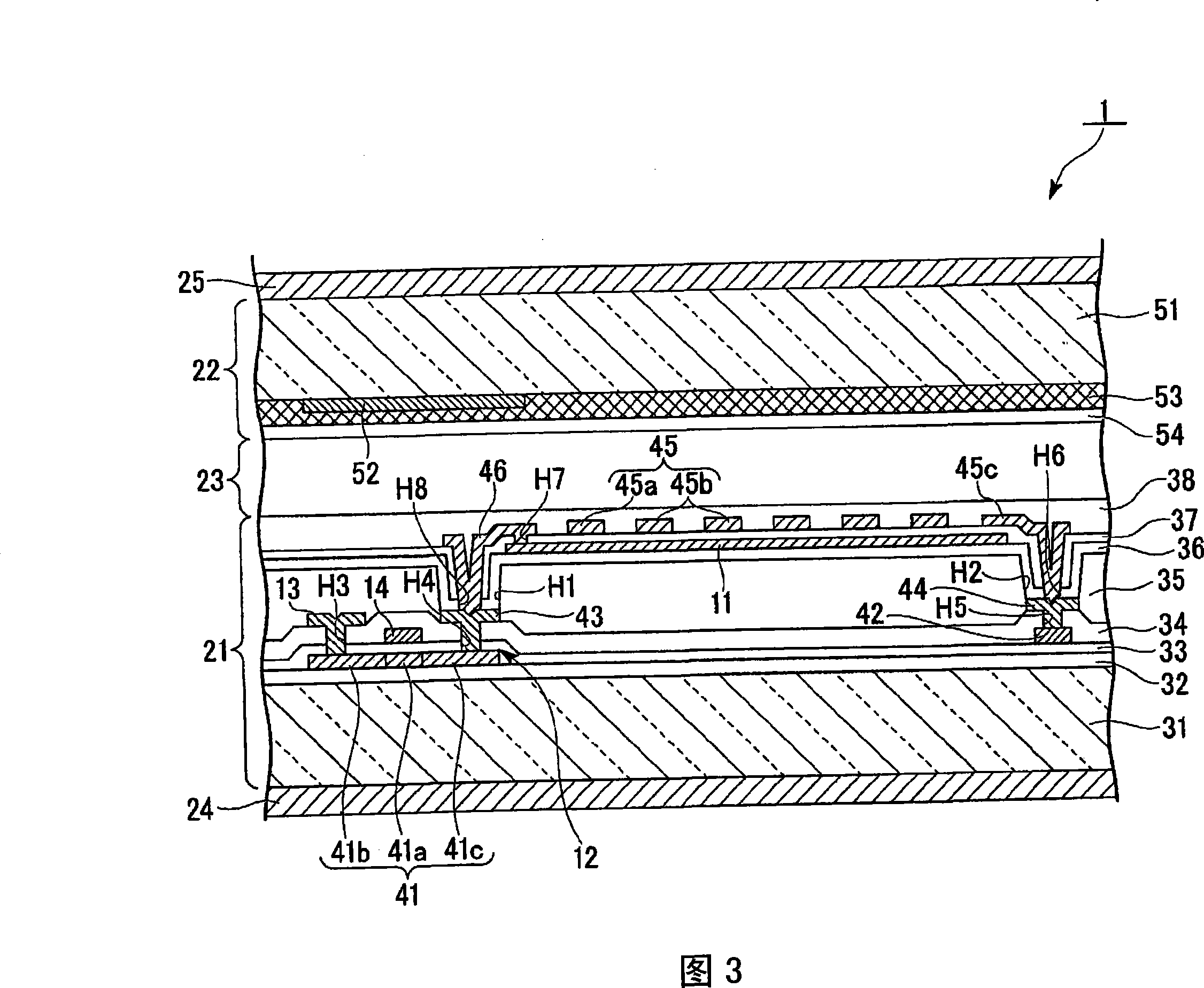

[0038] Hereinafter, a first embodiment of the liquid crystal display device of the present invention will be described with reference to the drawings. In addition, in each drawing used for the following description, since each member is set to the recognizable size, reduction ratio can be changed suitably. Here, FIG. 1 is an equivalent circuit diagram of a liquid crystal display device, FIG. 2 is a plan view showing a sub-pixel region, and FIG. 3 is a sectional view taken along the line A-A of FIG. 2 .

[0039] [Liquid crystal display device]

[0040] The liquid crystal display device 1 of the present embodiment is a transmissive color liquid crystal display device in which one pixel is constituted by three sub-pixel regions that output light of each color R (red), G (green), and B (blue). Here, a display area serving as a minimum unit constituting a display is referred to as a "sub-pixel area".

[0041] First, a schematic configuration of the liquid crystal display device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com