Stepless adjustable great current generating circuit for driving electromagnetic performer

An electromagnetic actuator and current generation technology, applied to electromagnets, electromagnets with armatures, etc., can solve problems such as production accidents, and achieve the effects of fast response, good reliability, and simple structure

Inactive Publication Date: 2011-01-05

SOUTHEAST UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in this case, if the embedded processor has a program "runaway" fault, the state of the MOS tube will be turned on but not off, or off but not on, so that the current suddenly drops to 0 or increases. Large to the full range, the electromagnetic actuator suddenly shuts down or rotates to the maximum angle, which can easily cause production accidents

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

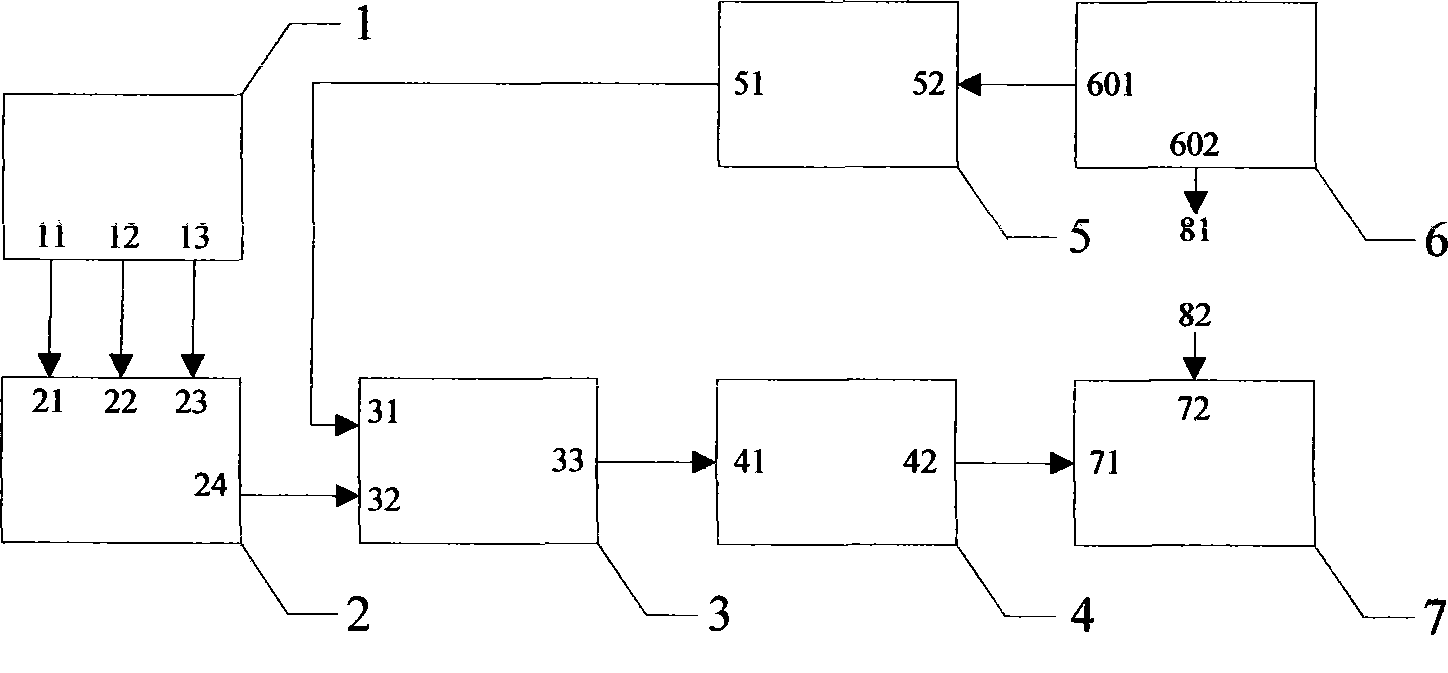

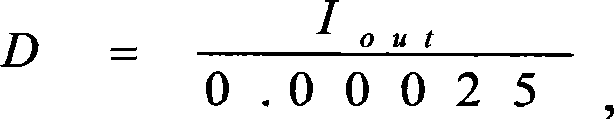

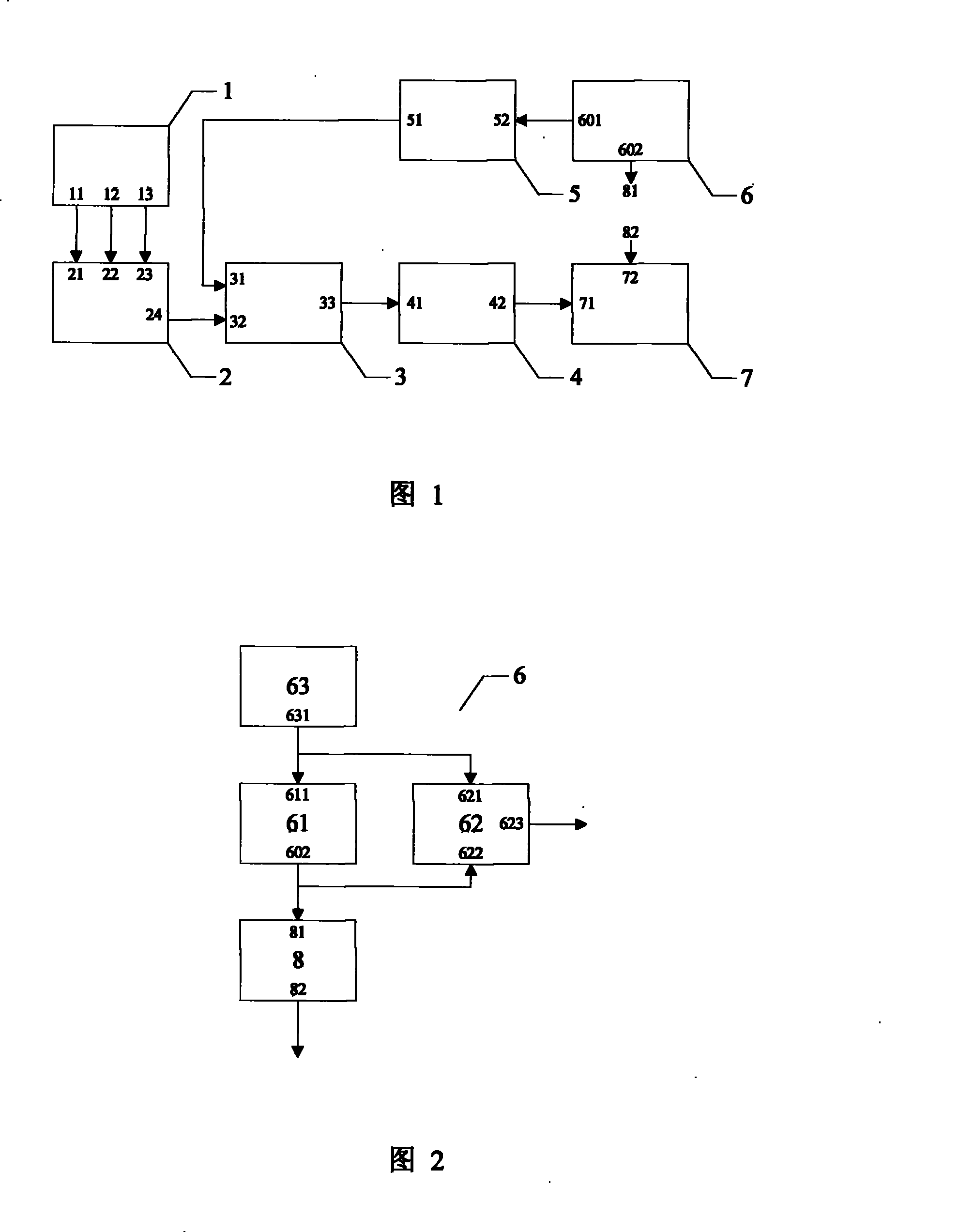

The invention discloses a stepless adjustable heavy current generation circuit used for driving an electromagnetic actuator, which comprises a processor, a digital-analog converter, a voltage comparator, an isolated-form power tube driver, an isolated-form operational amplifier, a current sample module and an insulated gate bipolar transistor. The processor is connected with the digital-analog converter; the digital-analog converter is connected with the voltage comparator; the voltage comparator is connected with the isolated-form power tube driver; the isolated-form power tube driver is connected with the insulated gate bipolar transistor; the isolated operational amplifier is connected with the voltage comparator; the current sample module is connected with the isolated operational amplifier, and is connected with the positive input end of the electromagnetic actuator; the collector input end of the isolated gate bipolar transistor is connected with the reverse input end of the electromagnetic actuator. The invention has the advantages of high circuit reliability to prevent industrial accident, convenient set of the driving current value and accurate and reliable stepless adjustment.

Description

A Stepless Adjustable Large Current Generating Circuit for Driving Electromagnetic Actuators technical field The invention relates to a 0-5A stepless adjustable large current generating circuit with strong anti-interference ability and good reliability, which is especially suitable for driving electromagnetic actuators. Background technique Electromagnetic actuators are widely used in industrial production because of their simple structure, small size, convenient control, fast response, and good stability and precision. The construction of the electromagnetic actuator is an electromechanical component with a closed magnetic circuit. When the excitation coil inside the actuator passes current, a magnetic flux will be generated in the closed-loop magnetic circuit (conical stator core→housing stator core→air gap→moving armature→working air gap→conical stator core) and electromagnetic flux will be generated. force. Due to the action of the electromagnetic force, the return ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01F7/18

Inventor 周杏鹏朱文俊

Owner SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com