Cement bonding agent, road index mark cement dope and method for preparing road index mark by the same

A technology of cement binder and road marking, which is applied in the field of road marking paint and its production of road marking and cement binder, and can solve the problem of poor adhesion between paint and road surface and glass beads, high production cost, Low strength and other problems, to achieve the effect of flexible use, good environmental performance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A cement binder——A# cement binder is a mixture of the following materials, and the content of each component in the mixture is calculated as:

[0046] K 2 CrO 7 2H 2 O 0.10 CuSO 4 ·5H 2 O 0.60

[0047] KAl(SO 4 ) 2 12H 2 O 0.90 FeSO 4 ·7H 2 O 0.70

[0048] NaCl 0.31 Na 2 CO 3 0.30

[0049] CO(NH 2 ) 2 0.80H 3 BO 3 0.15

[0050] KMnO 4 0.40 95% medical alcohol 0.10

[0051] Na 2 SiO 3 80.00 H 2 O margin.

[0052] The above mixture is liquid, odorless, non-flammable and non-toxic, with a specific gravity of 1.35.

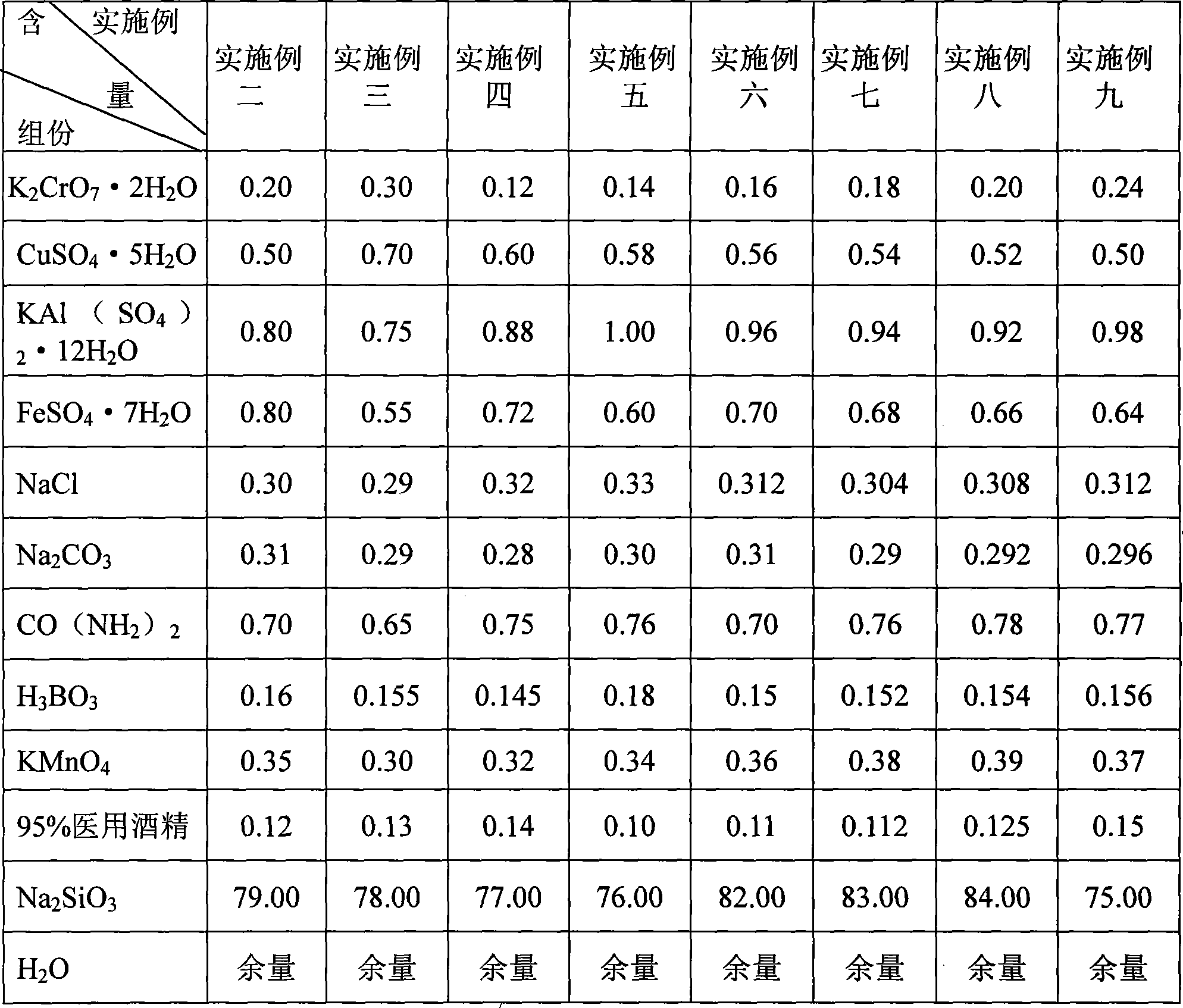

Embodiment 2 Embodiment 9

[0054] Various A# cement binders with different proportions are a mixture of the following materials, and the content of each component in the mixture is calculated as:

[0055] K 2 CrO 7 2H 2 O 0.10~0.30 CuSO 4 ·5H 2 O 0.50~0.70

[0056] KAl(SO 4 ) 2 12H 2 O 0.75~1.00 FeSO 4 ·7H 2 O 0.55~0.80

[0057] NaCl 0.29~0.35Na 2 CO 3 0.28~0.32

[0058] CO(NH 2 ) 2 0.65~0.80H 3 BO 3 0.14~0.18

[0059] KMnO 4 0.30~0.40 95% medical alcohol 0.10~0.15

[0060] Na 2 SiO 3 75.00~85.00H 2 O margin.

[0061] For the specific content of each component in the A# cement binder of each of the above examples, please refer to Attached Table 1.

[0062] The above-mentioned A# cement binder is liquid, odorless, non-flammable, non-toxic, and has a specific gravity of 1.25-1.45.

[0063] The production method of Embodiment 1 to Embodiment 9 is: grind all the solid materials, add 100°C hot water in proportion and stir for 10 mi...

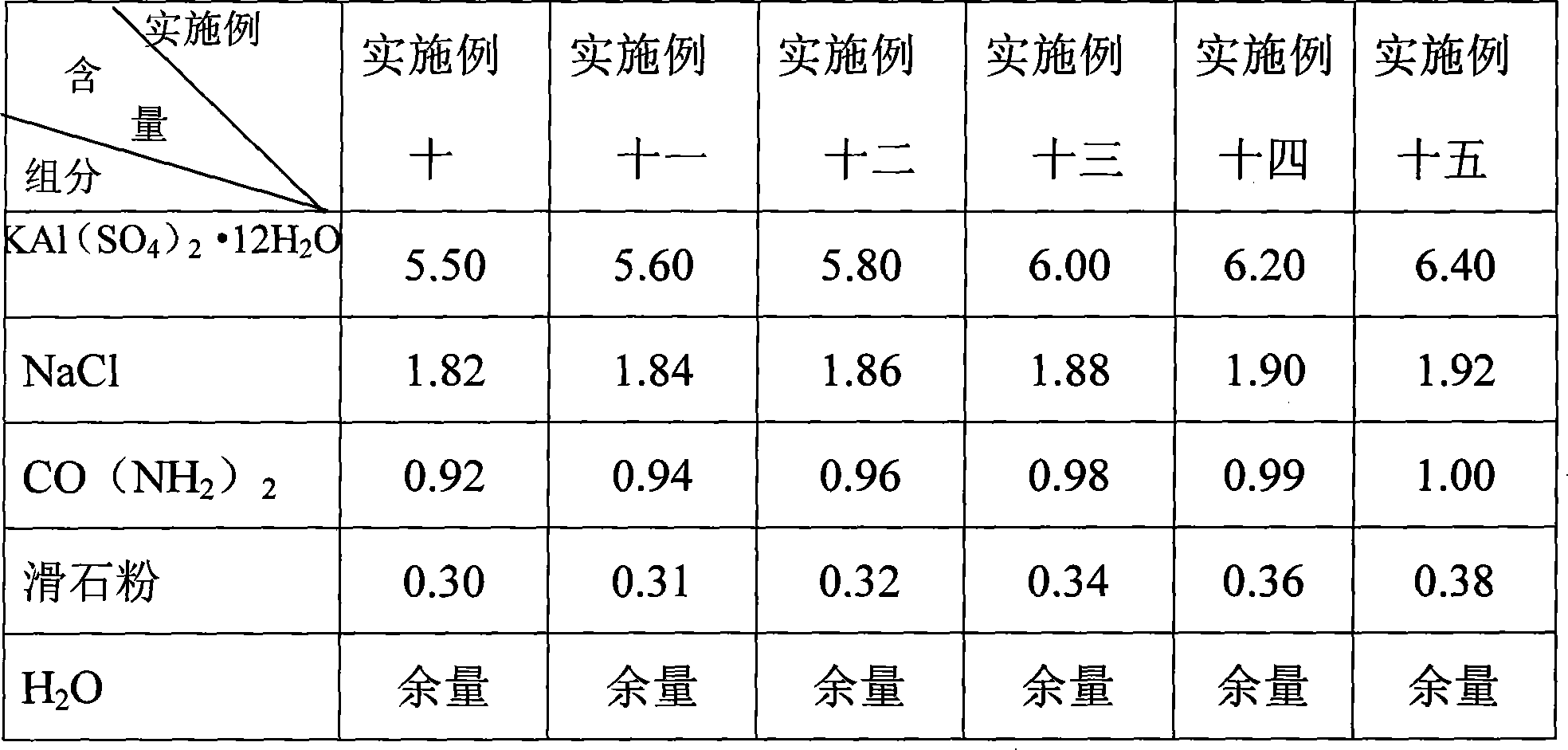

Embodiment 10 Embodiment 15

[0065] A B# cement binder used in conjunction with or mixed with A# cement binder, the B# cement binder is a mixture of the following materials, and the content of each component in the mixture is calculated as:

[0066] KAl(SO 4 ) 2 12H 2 O 5.50~6.50 NaCl 1.80~2.00

[0067] CO(NH 2 ) 2 0.90~1.00 Talc powder 0.30~0.40

[0068] h 2 O margin.

[0069] The specific content of each component in the above-mentioned each embodiment B# cement binder is shown in attached table two.

[0070] The above-mentioned B# cement binder is liquid, odorless, non-flammable and non-toxic, with a specific gravity of 1.045-1.09.

[0071] The production method of Examples 10 to 15 is as follows: Grind all the solid materials, add water and stir for 10 minutes until all the materials are dissolved, and then filter to obtain B# cement binder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com