Electric stove

A technology of electric furnace and power supply, which is applied in the direction of household furnace/stove, electric heating fuel, heating arrangement of electric heating plate, etc. It can solve the problems of difficulty in realizing automation and lack of automation, so as to realize automatic control, ensure normal operation and reduce the temperature in the furnace Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

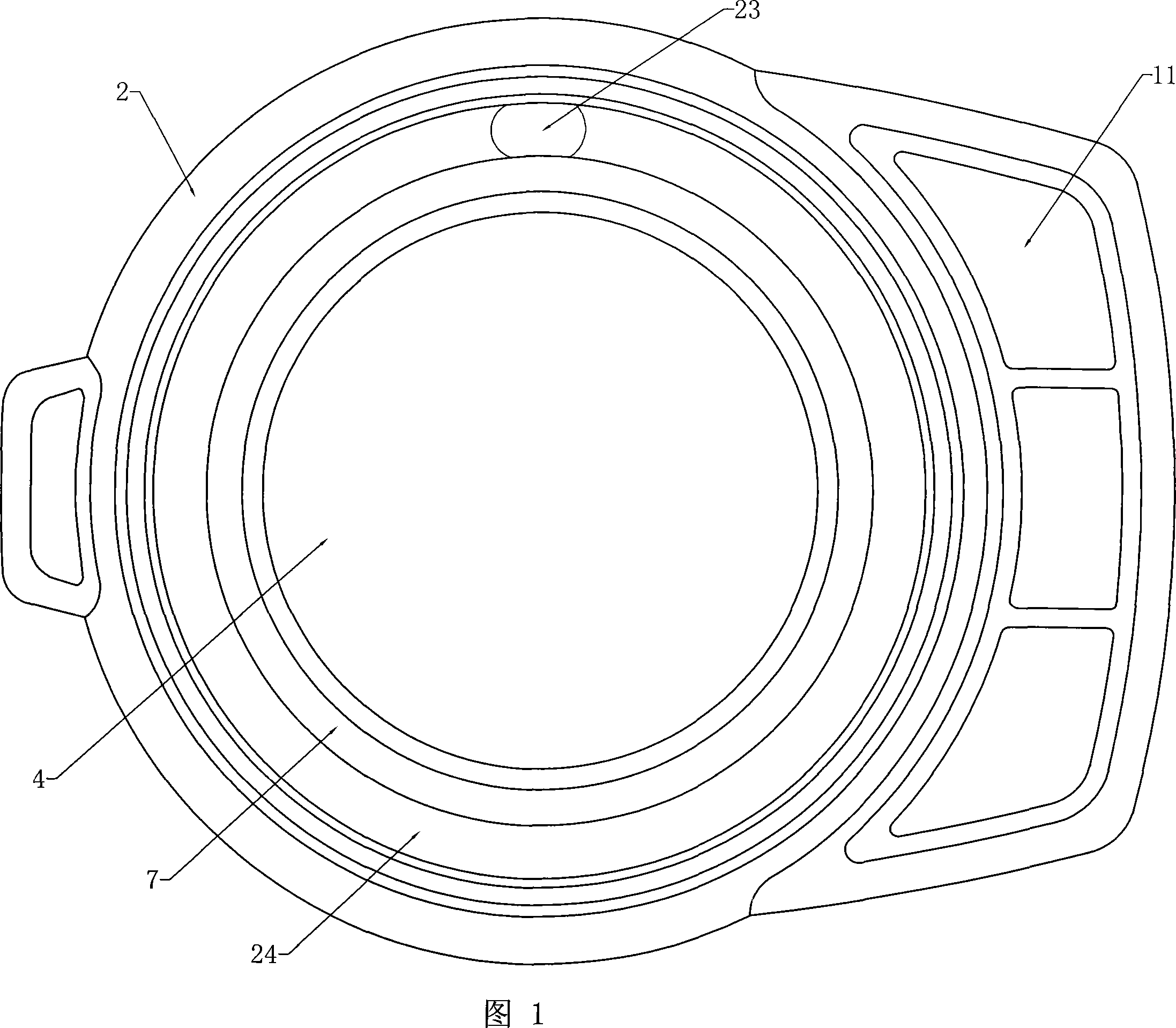

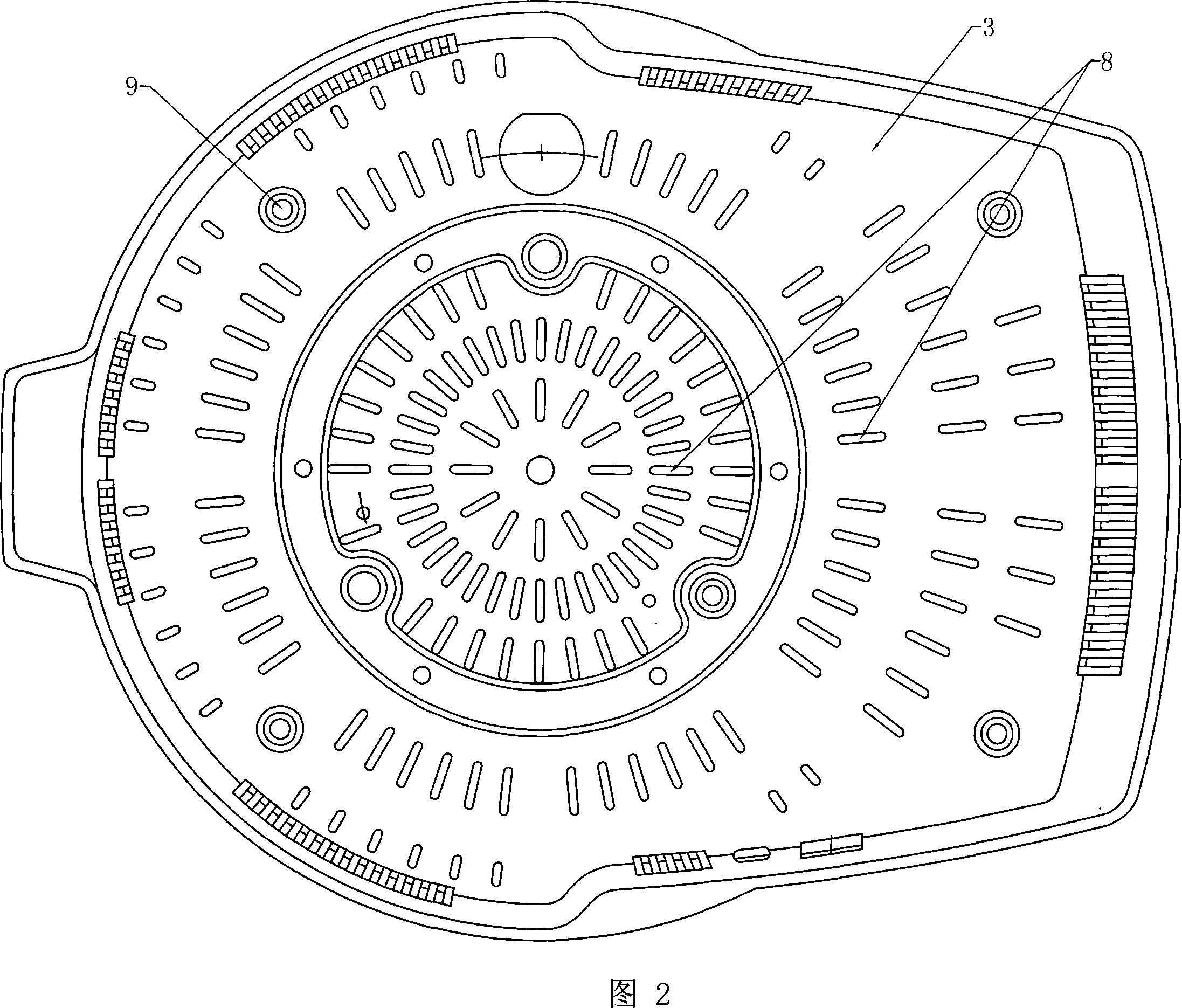

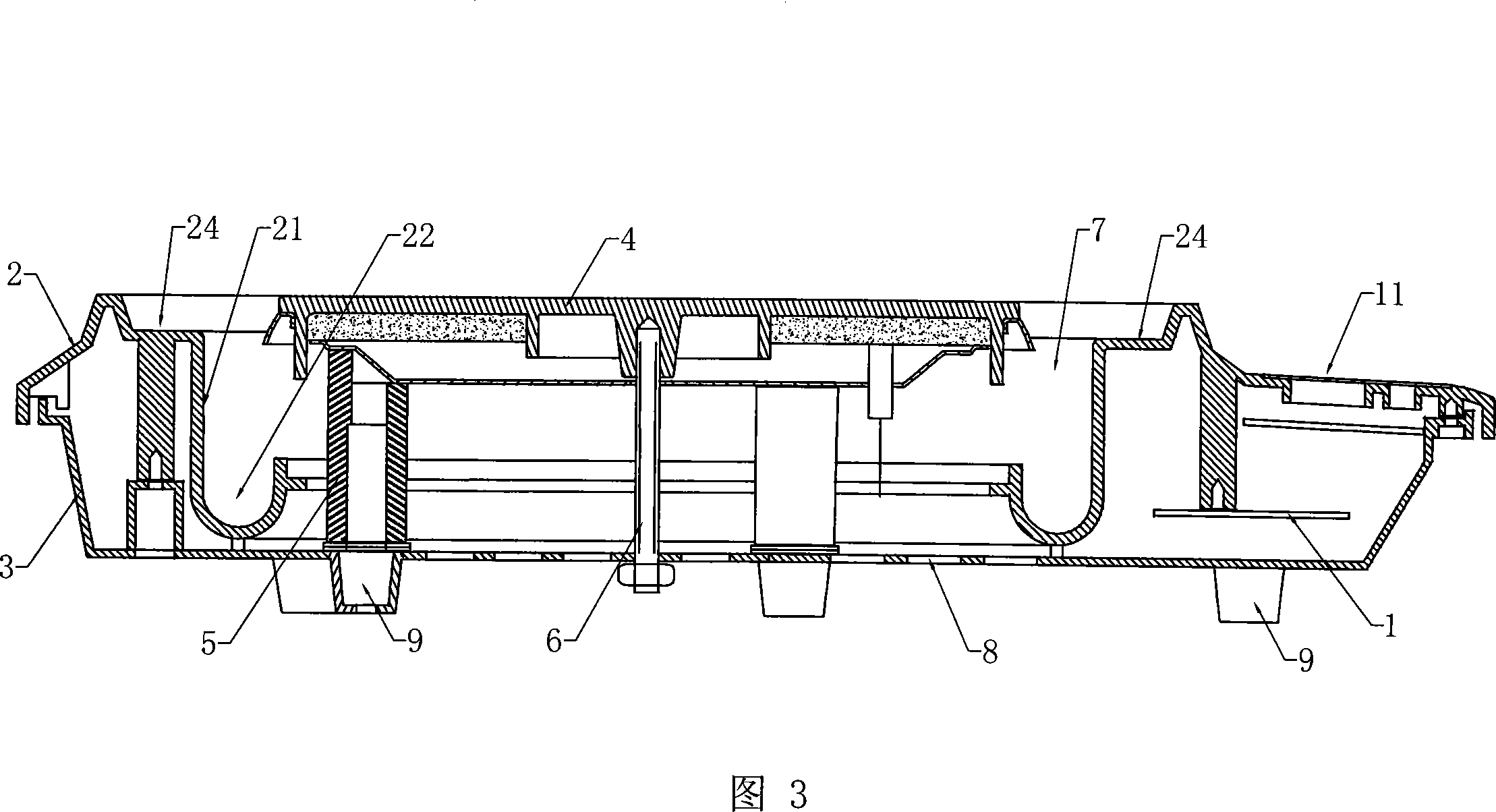

[0012] Referring to Fig. 1-Fig. 4, the electric furnace includes an upper shell 2, a lower shell 3, an electric heating plate 4 and a control circuit board 1, the control circuit board 1 is arranged under the front part of the upper shell 2, and the control circuit board 1 is respectively It is connected with the power supply, the control panel 11 and the electric heating plate 4. On the upper shell 2, there is a cavity for accommodating the electric heating plate 4 and a soup overflow tank 24. The electric heating plate 4 is supported by three porcelain columns 5 and tightened by screws and nuts 6. Fixed on the lower casing 3, between the electric heating plate 4 and the cavity wall 21 of the upper casing 2, an isolation groove 7 is provided, and the isolation groove 7 communicates with the vent hole 8 on the lower casing 3. In the isolation groove 7 The bottom of the soup row is provided with a soup row tank 22, and the tank body of the soup row tank 22 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com