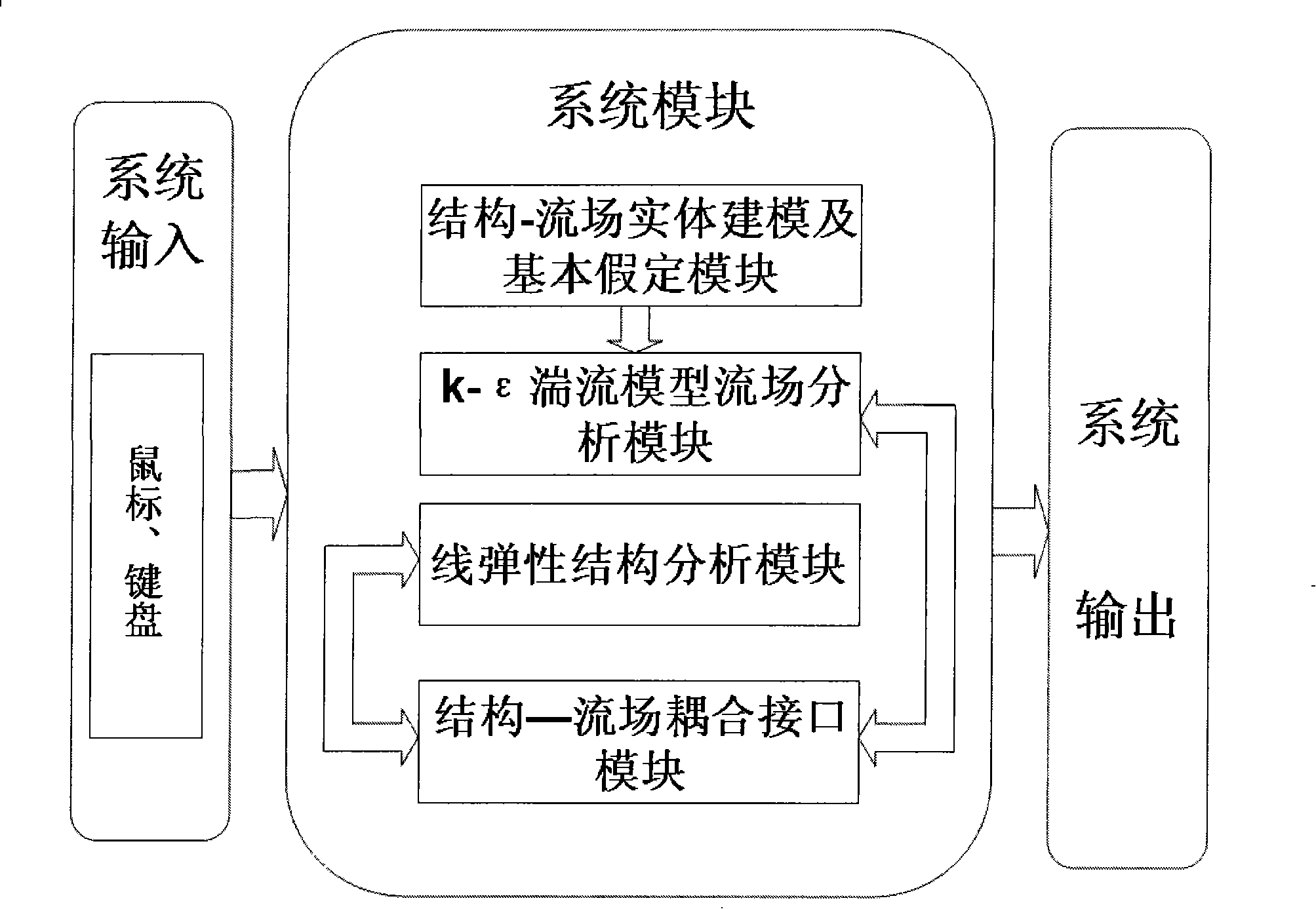

Flex wing minisize aerial craft fluid-solid coupling numerical value emulation method

A micro-aircraft, fluid-solid coupling technology, applied in the direction of instruments, image data processing, electrical digital data processing, etc., can solve problems such as errors, and achieve the effect of speeding up the research and development process and reducing development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]In order to better understand the technical solution of the present invention, the above algorithm is applied to the analysis of a flexible wing MAV with a cruising speed of 10m / s and an angle of attack of 6 degrees for further description.

[0044] Step 1 Establish a 3D solid model of the flexible wing MAV. According to the actual size of the flexible MAV, it is input through the mouse, keyboard, etc., and its model is manually established by using Solidworks 3D modeling software, and the established 3D model is saved in the mav.sat format.

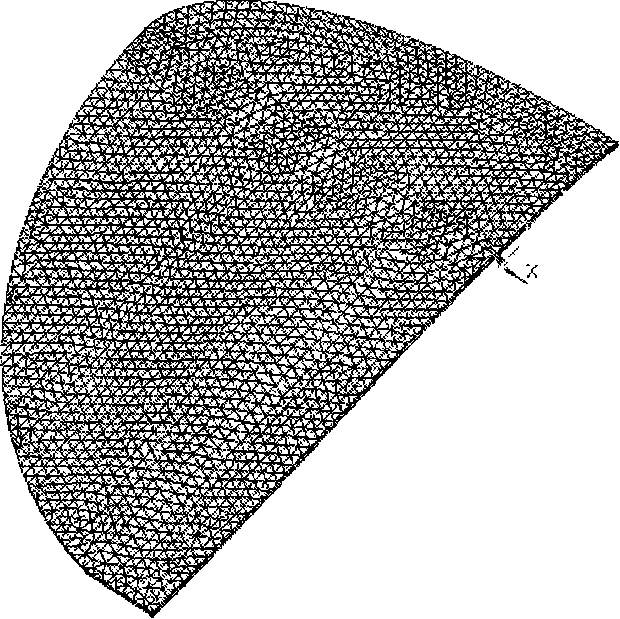

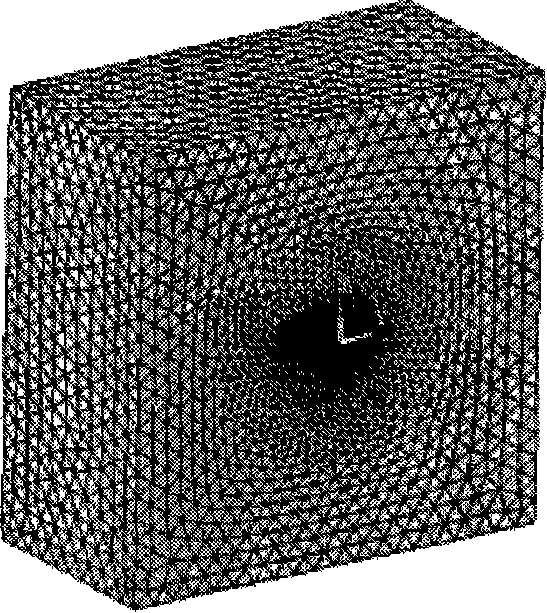

[0045] Step 2 meshes the flexible wing MAV model. Import the MAV 3D model in sat format obtained in step 1 into ANSYS software, and divide the 3D model into tetrahedral grids through mouse, keyboard and other input devices in the order from line to surface and from surface to volume to achieve continuous system discrete For the purpose of optimization, the grid model of the MAV wing structure is obtained and saved as a mav.db form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com