Automatically cooking method and apparatus

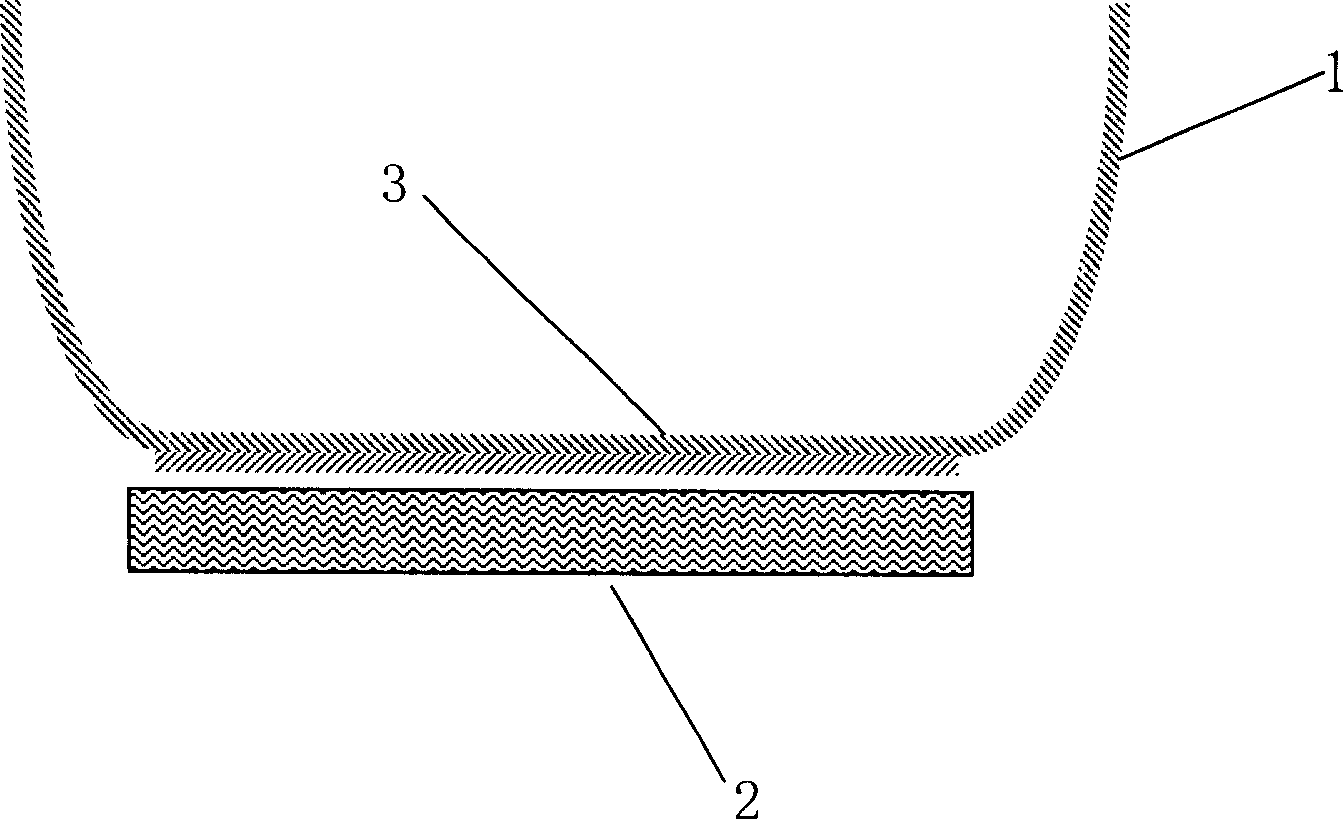

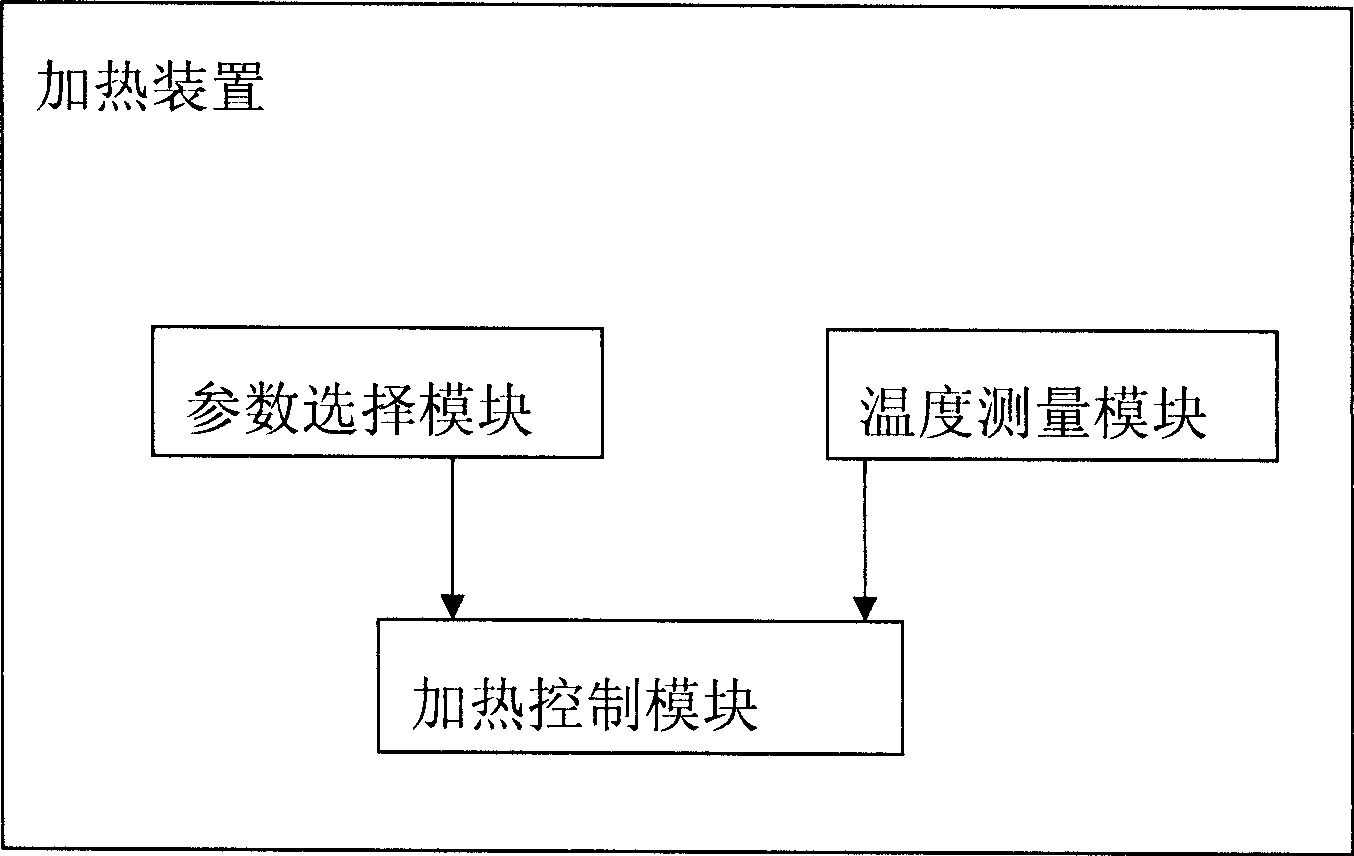

A technology for automatic cooking and cooking containers, which is applied to heating devices, cooking utensils, household appliances, etc., can solve problems such as poor fluidity and sticky soup, and achieve the effect of avoiding the phenomenon of sticking to the pot.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

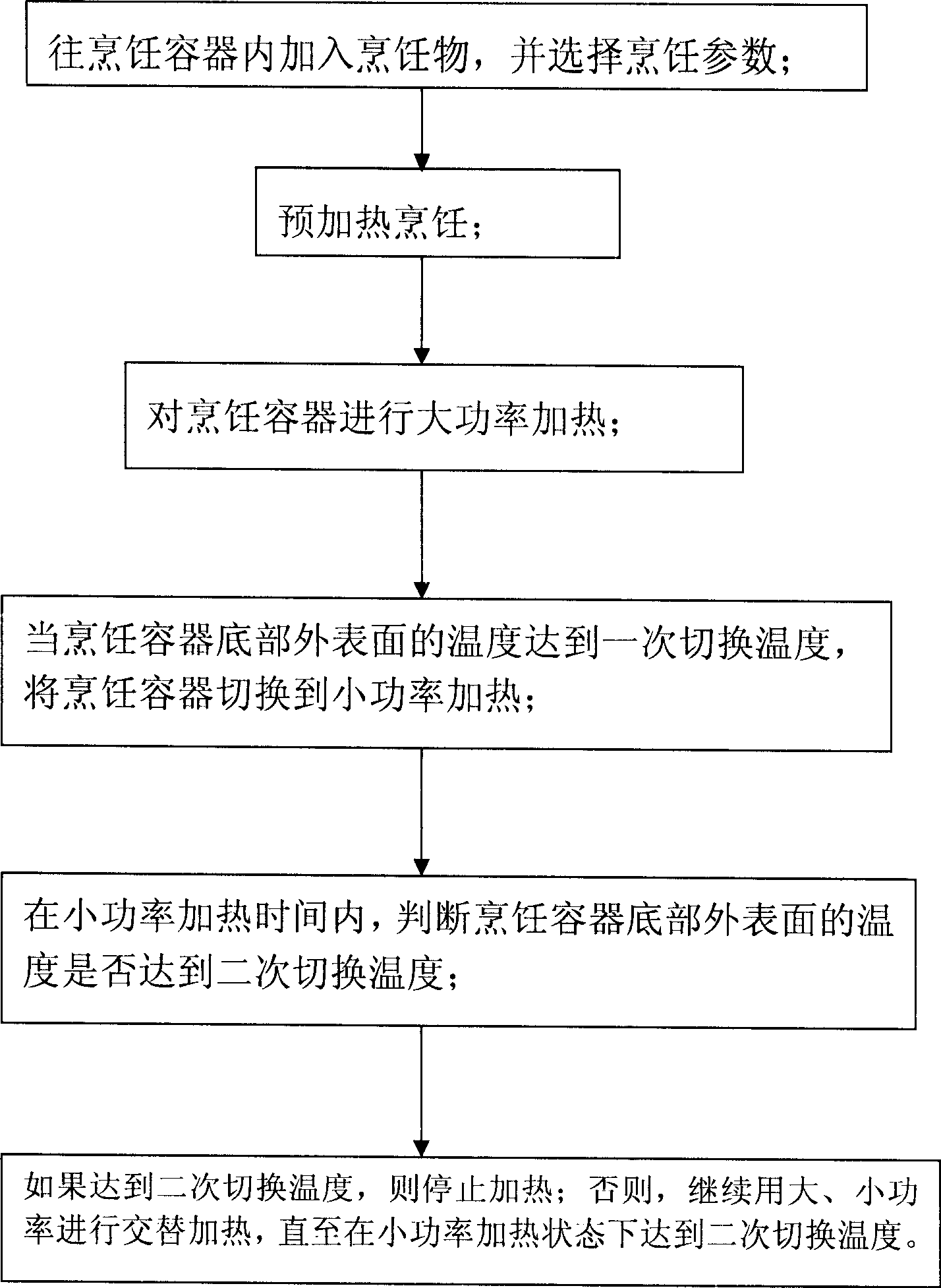

[0048] 2. Heat at 1000 watts for 9 minutes, when the temperature of the outer surface of the bottom of the pot reaches 130 degrees; observe that the pot is basically dry, but there is still a small amount of water;

[0049] 3. Switch to 500 watts and heat for 2 minutes. The temperature of the outer surface of the bottom of the pot reaches 130 degrees, and the pot is completely dry.

[0050] Example 2

Embodiment 2

[0052] 2. Heating at 1000 watts for 7 minutes, the temperature of the outer surface of the bottom of the pot reaches 130 degrees; observe that there is still obvious moisture in the pot;

[0053] 3. Switch to 500 watts and heat for 4 minutes. The temperature of the outer surface of the bottom of the pot does not reach 120 degrees, and there is no dry pot;

[0054] 4. Then switch to 1000 watts and heat for 1 minute, and the temperature of the outer surface of the bottom of the pot reaches 130 degrees; observe that the pot is basically dry, but there is still a small amount of water;

[0055] 5. Then switch to 500 watts and heat for 2 minutes. The temperature of the outer surface of the bottom of the pot reaches 120 degrees, and the pot is completely dry.

[0056] Example 3

Embodiment 3

[0058] 1. Add the cleaned fish, dried yellow sauce, sugar, cooking wine, salt, aniseed, onion, ginger and 250ml of water into the pot.

[0059] 2. Start heating with high heat. About 20 minutes or so, the temperature of the bottom of the pot reaches the switching temperature, and then immediately turn the heat to low heat (see Figure 4 ). At this time, a large amount of water will be found in the actual observation pot.

[0060] 3. Heat on low heat for 4 minutes. Although the temperature tends to rise, it does not exceed 110 degrees; (see Figure 5 )

[0061] 4. After heating for 4 minutes, switch to high-power heating. After high-power heating, the temperature continues to rise, and it takes 60 seconds to reach the switching temperature;

[0062] 5. Then switch to low power heating (see Figure 6 ). At this time, observe that there will still be a lot of water in the pot;

[0063] 6. Same as the above process, it has gone through 3 similar processes (see Figure 7 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com