Arm rest lift side sheet and its processing method

A processing method and side plate technology, applied in the field of escalator parts and components, can solve the problems of high labor intensity, difficulty in nesting, and affecting product quality, so as to reduce labor intensity of workers, facilitate mass production, Facilitate the effect of handling and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

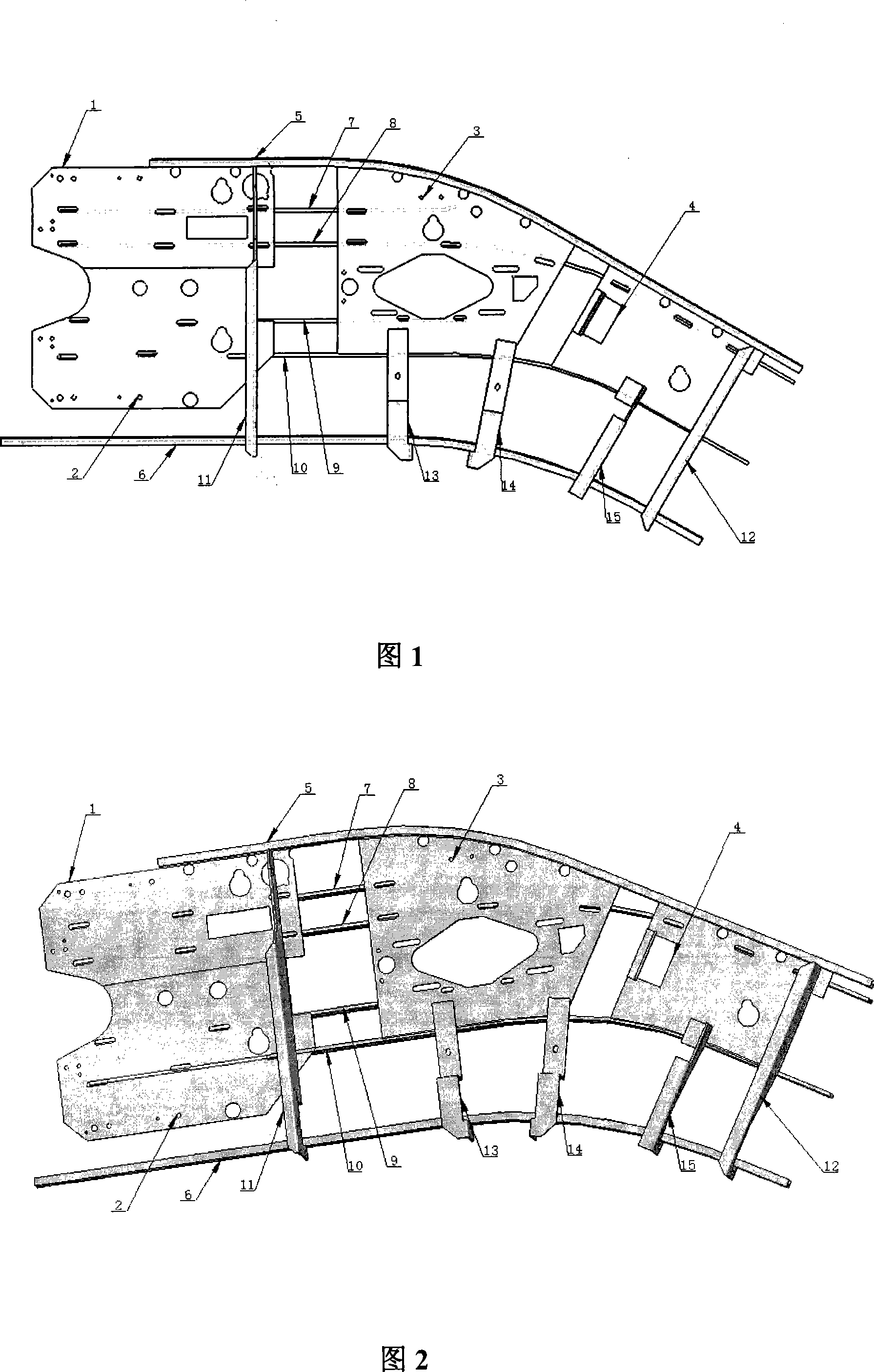

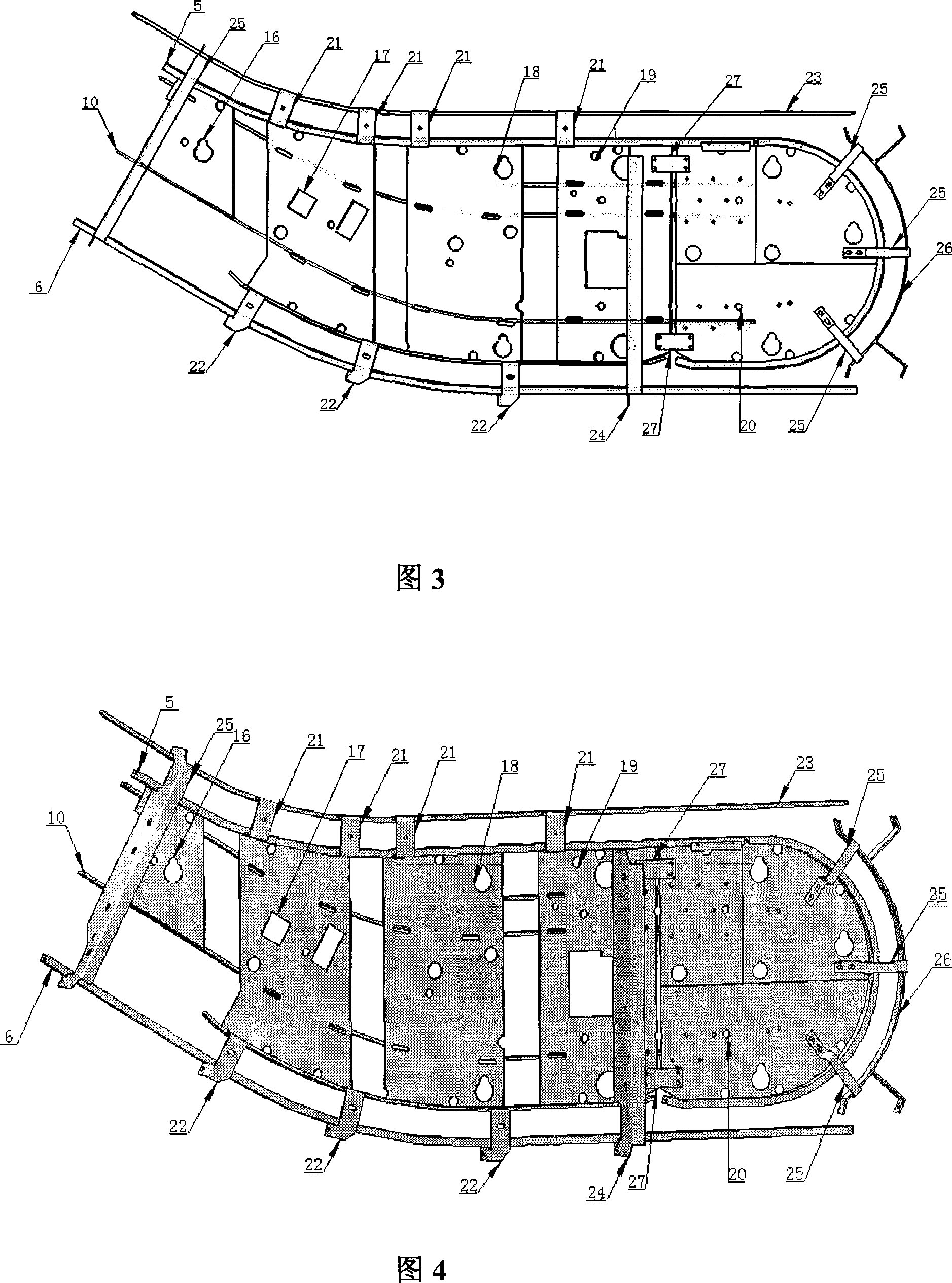

[0022] The detailed technical contents and embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Accompanying drawing shows the preferred embodiment of the present invention, below in conjunction with the structure that accompanying drawing shows, further describe the detailed technical content of the present invention.

[0024] The escalator side plate provided by the present invention,

[0025] Among them: the upper and side panels of the escalator can be decomposed and designed into at least two panels, such as the diagram number 1 to 4, and the panels 1 and 2 can also be a whole panel, or more panels can be divided according to needs Each plate can be connected by welding or other methods, such as: bolt connection, riveting, etc.; it also includes at least three bending parts, such as icon numbers 13 to 15, and at least two or more connections parts, such as icon numbers 11-12; it also includes main wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com