High hardness high precision metal parts inner pore outer round grinding material

A technology of metal parts and abrasive materials, which is applied in the field of high-efficiency processing of the inner and outer circles of small-diameter metal parts, can solve the problems of difficult to achieve quality indicators and low processing efficiency of abrasive materials, so as to improve efficiency, reduce production costs and ensure quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

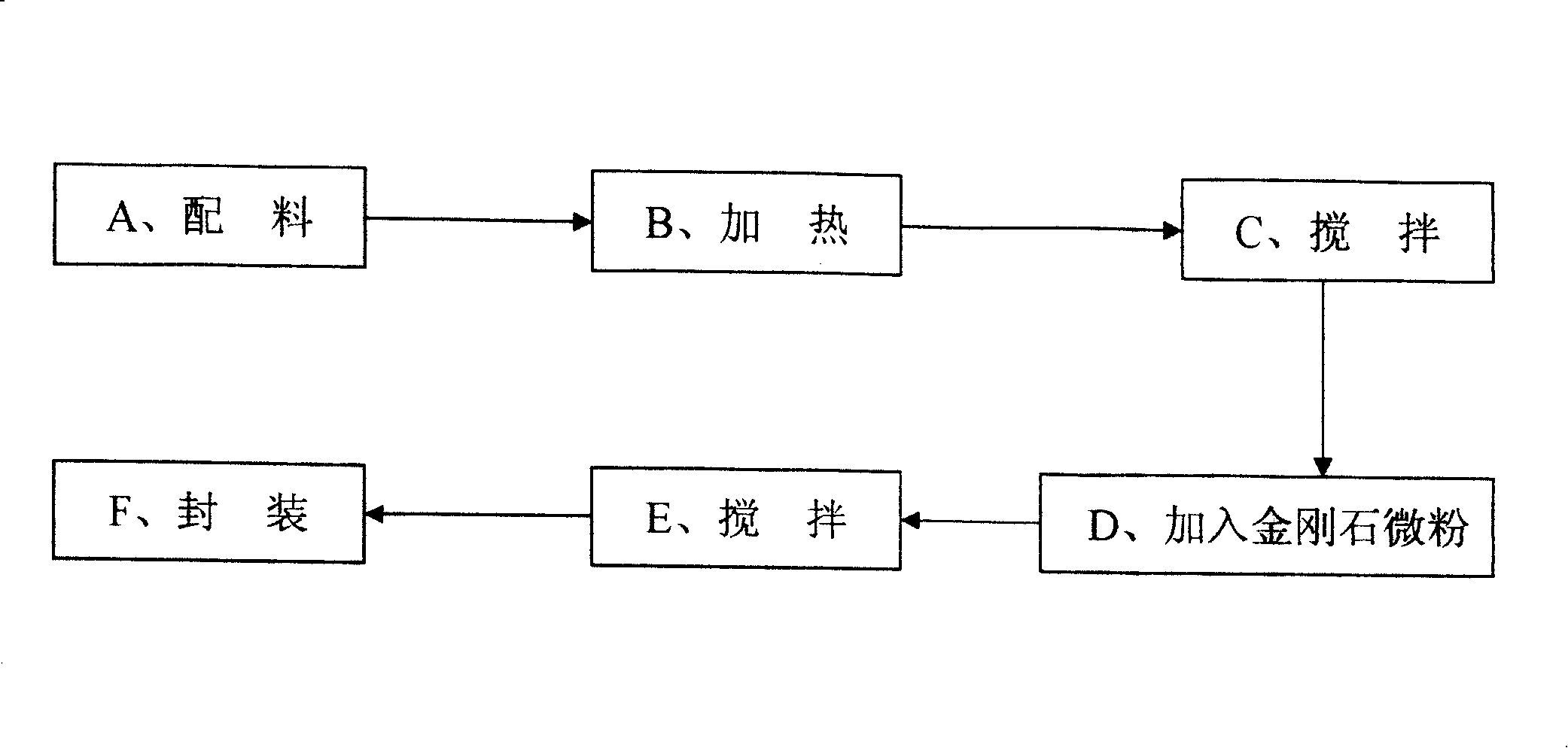

[0008] Referring to the accompanying drawings, the present invention adopts a process flow: A ingredients, B heating, C stirring, D adding diamond powder, E stirring, F packaging. Coarse abrasives, semi-finishing abrasives, fine abrasives, and polishing abrasives are produced respectively.

[0009] 1. Coarse abrasive

[0010] A, ingredients: 46% (300g) of stearic acid, 31% (200g) of lard, and 8% (50g) of lubricating grease are mixed together; B, heating: heat the mixture of the previous process until stearic acid , lard, and lubricating grease are melted into liquid; C, stirring: put the liquid of the mixture into the stirring equipment and stir evenly; D, add diamond micropowder: add 15% diamond micropowder W to the liquid after stirring 20 (100g); E, stirring: Stir the mixture of the previous process; if it solidifies, it can be heated and then stirred, and the stirring time can be slightly longer than the stirring time of the C process, until it is evenly stirred, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com