Gasifier liner

A gasifier and bushing technology, applied in the details of the gasification device, the mechanical details of the gasification device, and the manufacture of combustible gas, can solve the problems of changing the performance and efficiency of the gasifier and weakening the ability of the combined power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

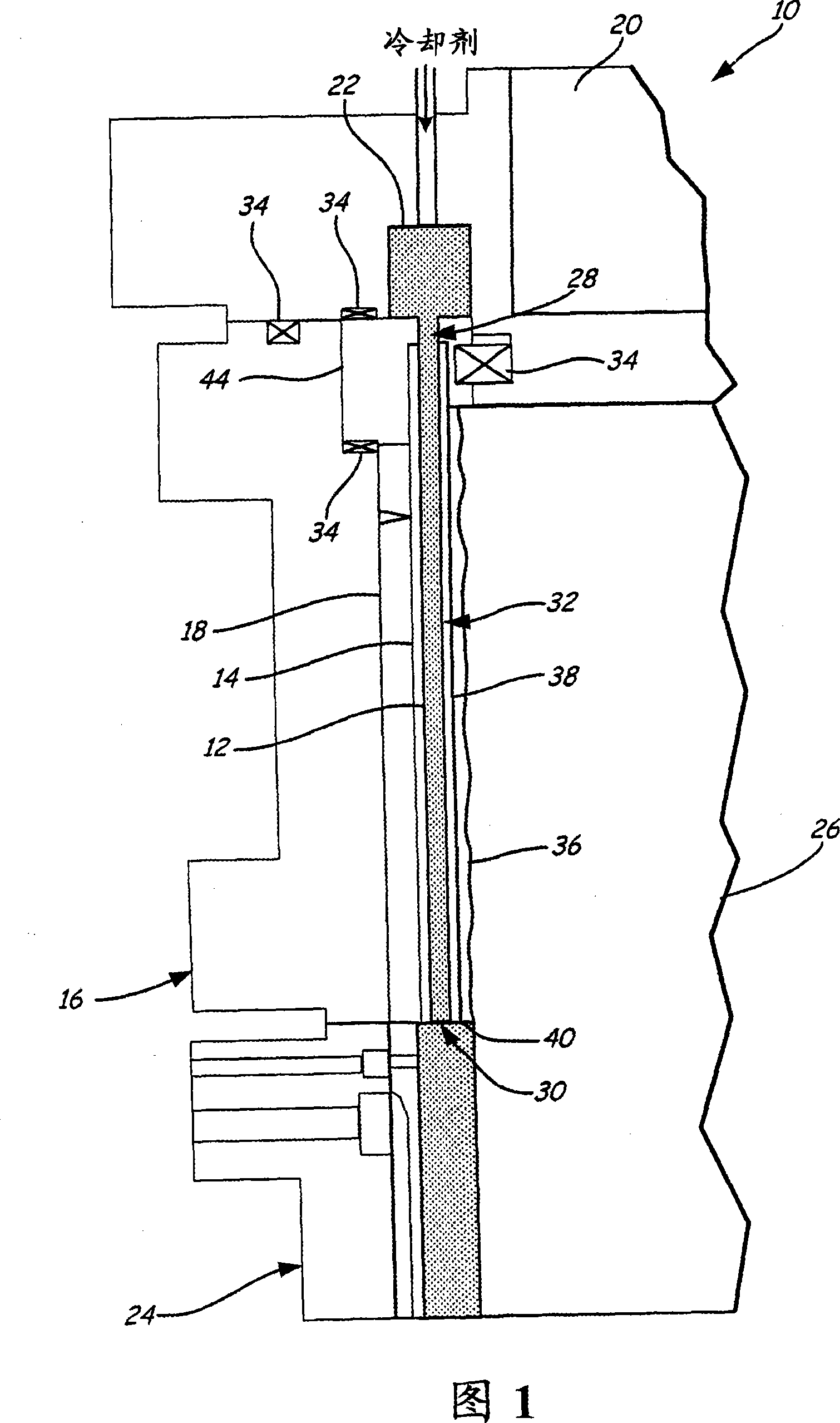

[0014] Figure 1 shows a cross-sectional view of a gasifier reactor 10 generally comprising a coolant passage 12, a representative liner 14, a metallic pressure vessel 16, an insulator 18, an injector 20, a coolant inlet Manifold 22 , quench section 24 and reaction chamber 26 . The use of the liner 14 in the gasifier reactor 10 provides low cost and extended life of the gasifier reactor 10 compared to other liners. Various technical risks of the gasification process are also reduced by the liner 14, as metal / ceramic bonding problems, crack propagation leading to leaks, and thermal growth mismatch are reduced or eliminated. The configuration of the liner 14 in the gasifier reactor 10 also allows for increased structural integrity of the coolant passage 12 . The liner 14 can be used in both a bleed air cooled liner cooling scheme and a regeneratively cooled liner cooling scheme in which coolant is poured into the gasification tank at the back end of the gasifier In the regenera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com