Generator of circularly polarized wave

A technology of circularly polarized waves and generators, which is applied in waveguide devices, waveguide openings, electrical components, etc., and can solve the problems of circularly polarized wave generators, such as the performance degradation of resistance to power consumption and low loss, difficulty in mass production and price reduction, etc. Problems, to achieve the effect of low power consumption resistance, easy processing, and reduced characteristic deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

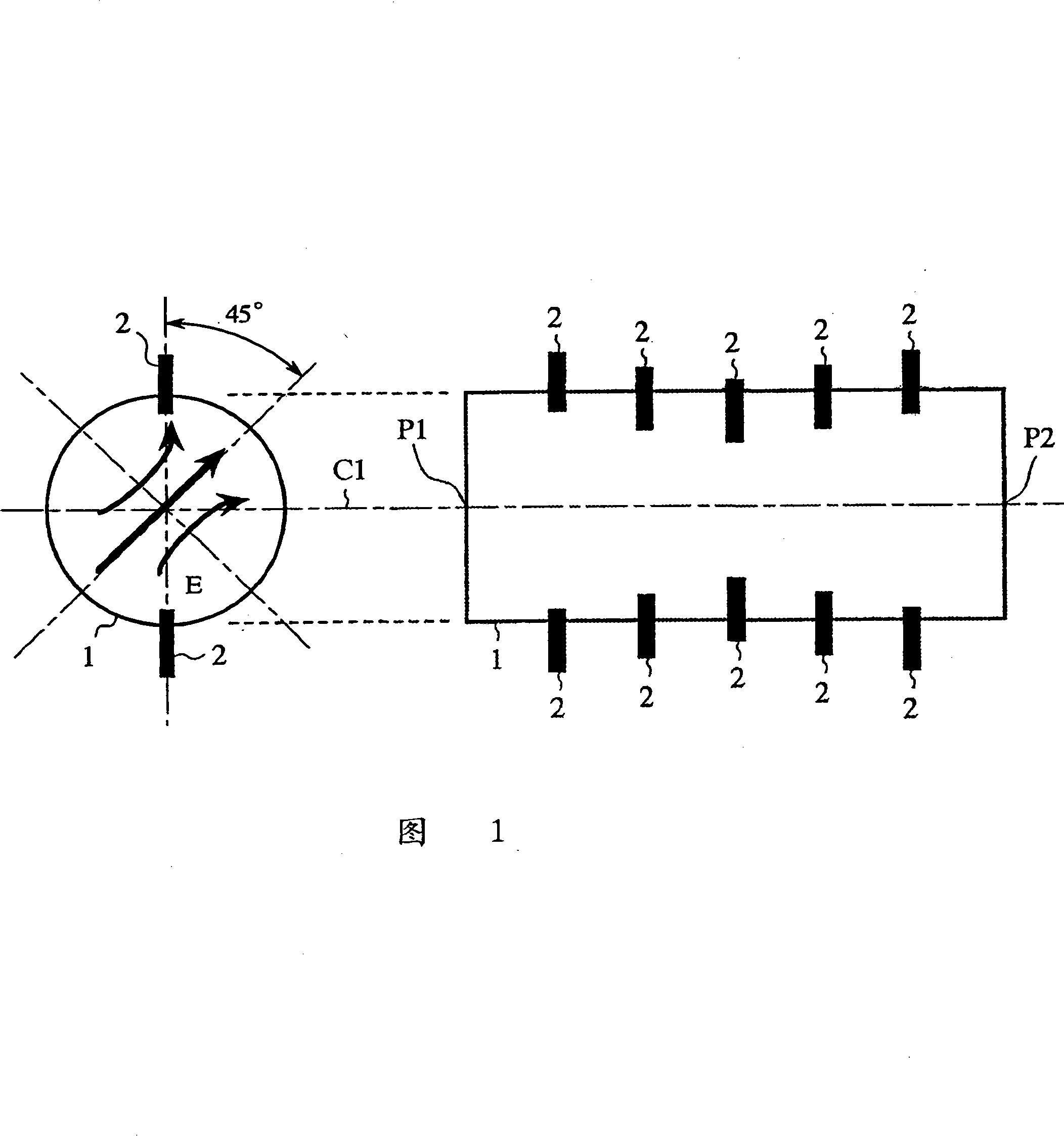

[0065] Hereinafter, in order to explain the present invention in more detail, the best mode for carrying out the invention will be described with reference to the drawings.

[0066] Embodiment 1

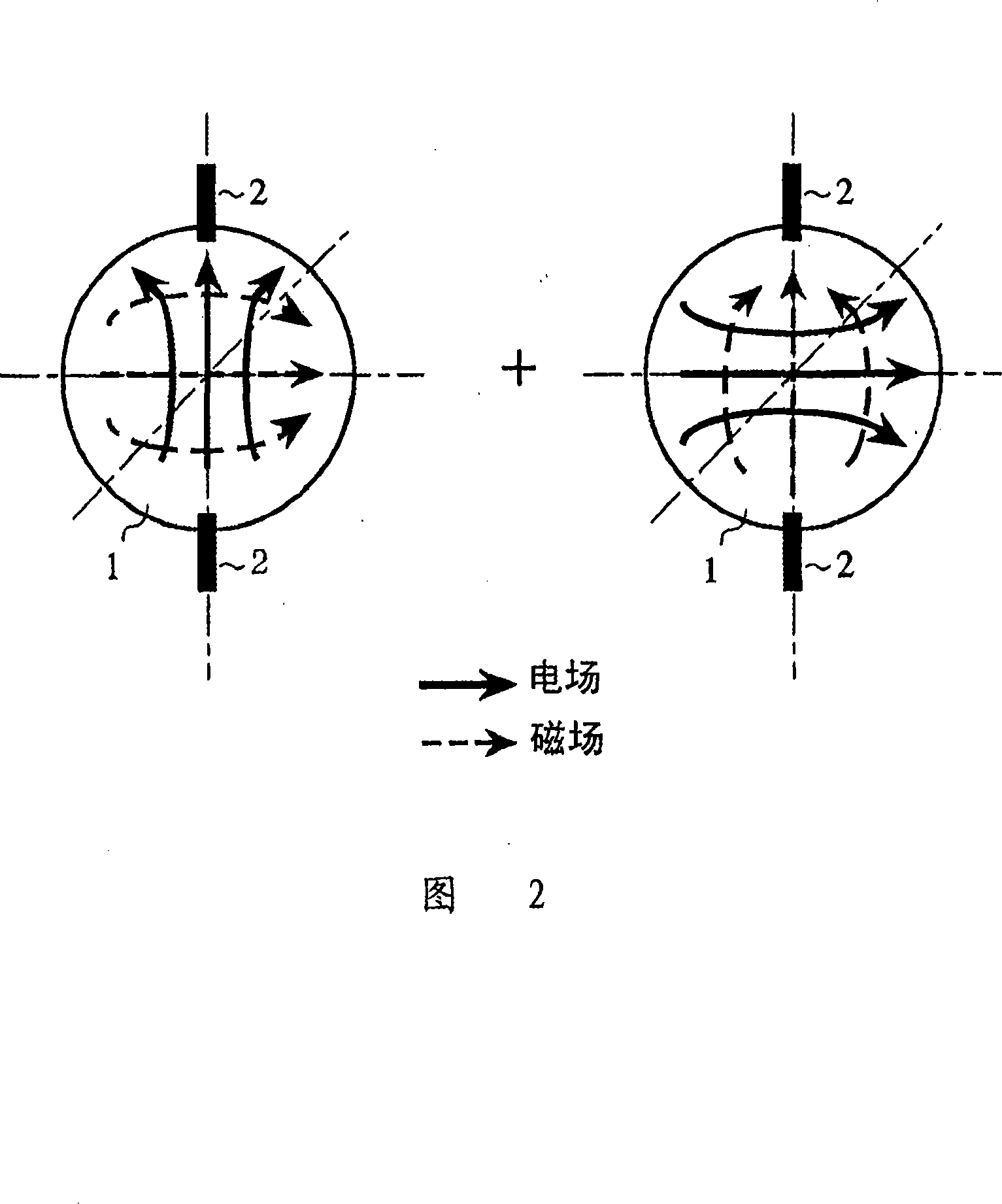

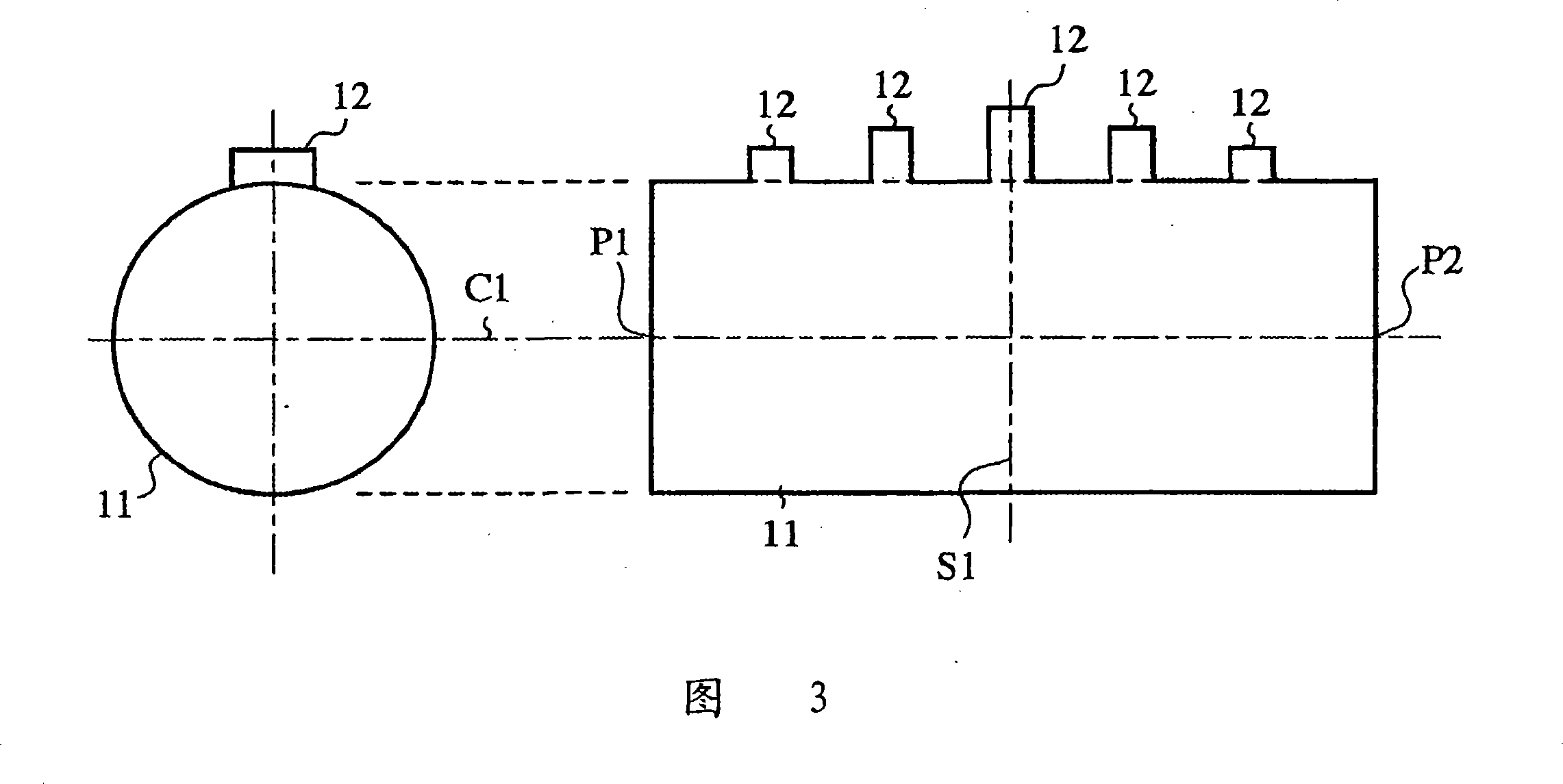

[0067] 3 is a schematic structural view showing a circularly polarized wave generator according to Embodiment 1 of the present invention. In the figure, 11 is a circular waveguide, and 12 is a plurality of side grooves, and the plurality of side grooves are opposite to the circular waveguide. 11 The plane S1, which is equally divided into left and right halves, is arranged on the side wall of the circular waveguide 11 along the direction of the tube axis C1 in such a manner that the volume is large at its central part, and between the input end P1 and the output end P2 The volume in the direction is small, and it becomes a symmetrical structure. 4 is an explanatory diagram showing electromagnetic field distribution of incident waves according to Embodiment 1 of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com