Polarization antenna for directional coupler feedback low profile back cavity round

A directional coupler, circularly polarized antenna technology, applied in antennas, slot antennas, circuits, etc., can solve the problems of low gain axis ratio, low axial ratio bandwidth, large volume, inability to plane integration, and inability to plane integration, etc., to improve practical use. Bandwidth, excellent radiation characteristics, the effect of increasing the 3dB axial ratio bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

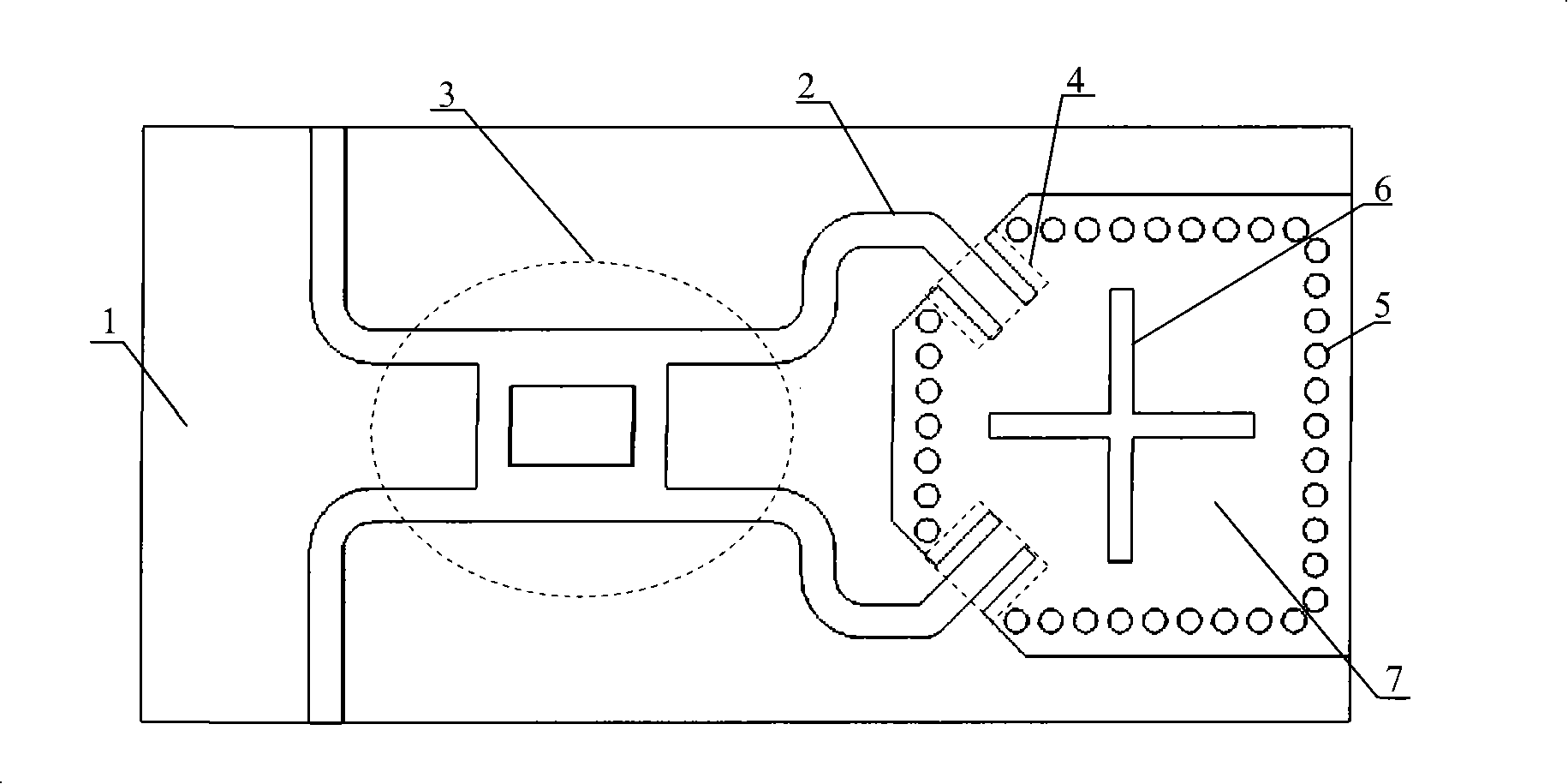

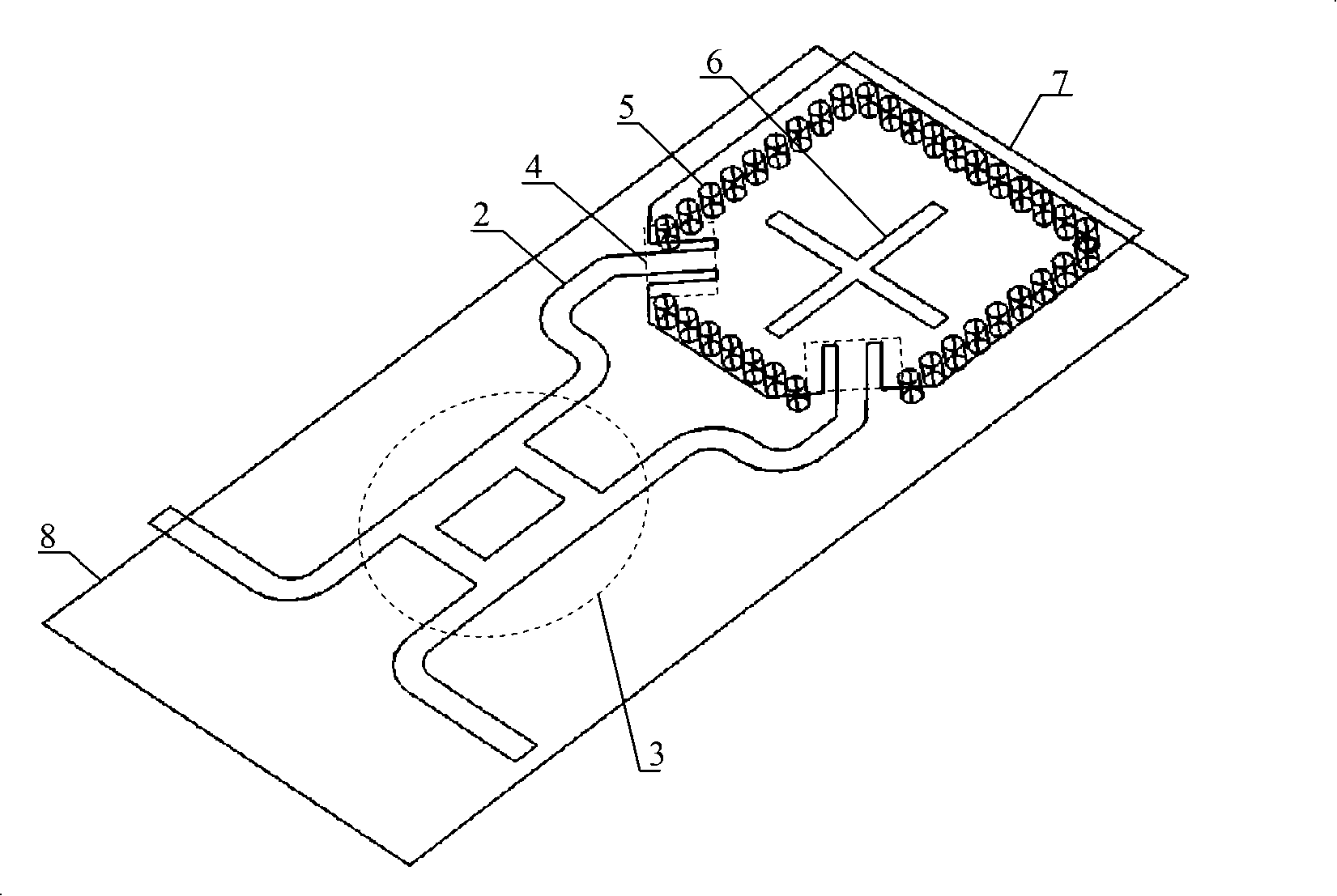

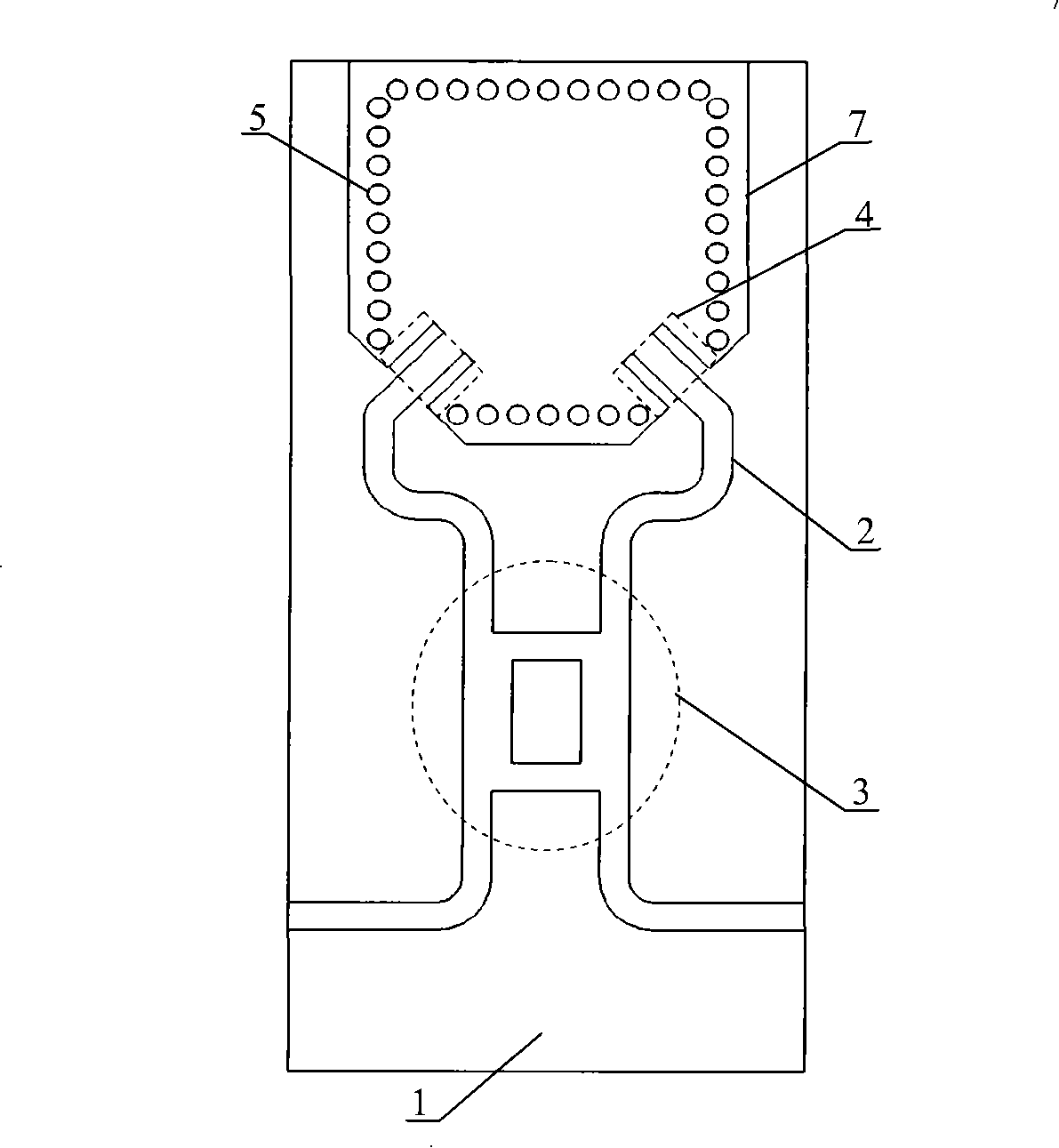

[0023] Such as figure 1 and 2 As shown, the directional coupler fed low-profile cavity-backed circularly polarized antenna includes a Rogers5880 dielectric substrate 1 with a thickness of 0.5 mm, and the two sides of the dielectric substrate 1 are coated with metal layers, which are respectively an upper metal layer 7 and a lower metal layer 8, Wherein the lower metal layer 8 is used as the stratum. Such as image 3, the upper metal layer 7 is etched with a microstrip line 2 for feeding, a branch line directional coupler 3 in the form of a microstrip (the dotted ellipse frame contains the part) and a coplanar waveguide transmission line 4 (the dotted line box contains the part), and the coplanar waveguide The transmission line 4 is a common-ground coplanar waveguide structure, the metal strip in the middle of which extends outward, and is connected to the two output ends of the branch line directional coupler 3 as a microstrip line 2 . The width of the 50 ohm microstrip lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com