Feed network system

A technology of feed network and network, applied in the field of feed network system, can solve the problems of obvious dispersion effect of phase shifting line, long processing cycle, inconsistent sintering shrinkage rate of substrate and slurry, etc., and achieves wide application value and applicability technology Effect, thermal performance and mechanical performance guarantee, the effect of good electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, the present invention will be further described with reference to the accompanying drawings and specific embodiments.

[0041] In order to illustrate the technical solutions of the embodiments of the present invention more clearly, the accompanying drawings of the embodiments will be briefly introduced below. Obviously, the drawings in the following description are only some embodiments of the present invention, which will be useful to those skilled in the art. In other words, on the premise of no creative work, other drawings can also be obtained from these drawings.

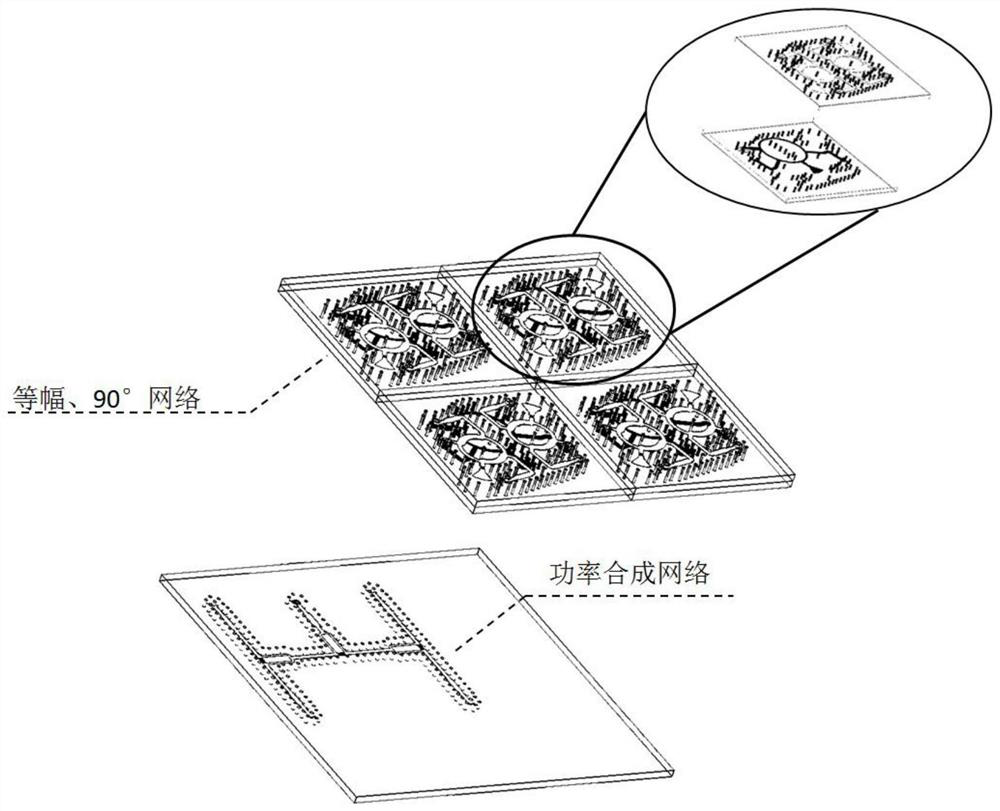

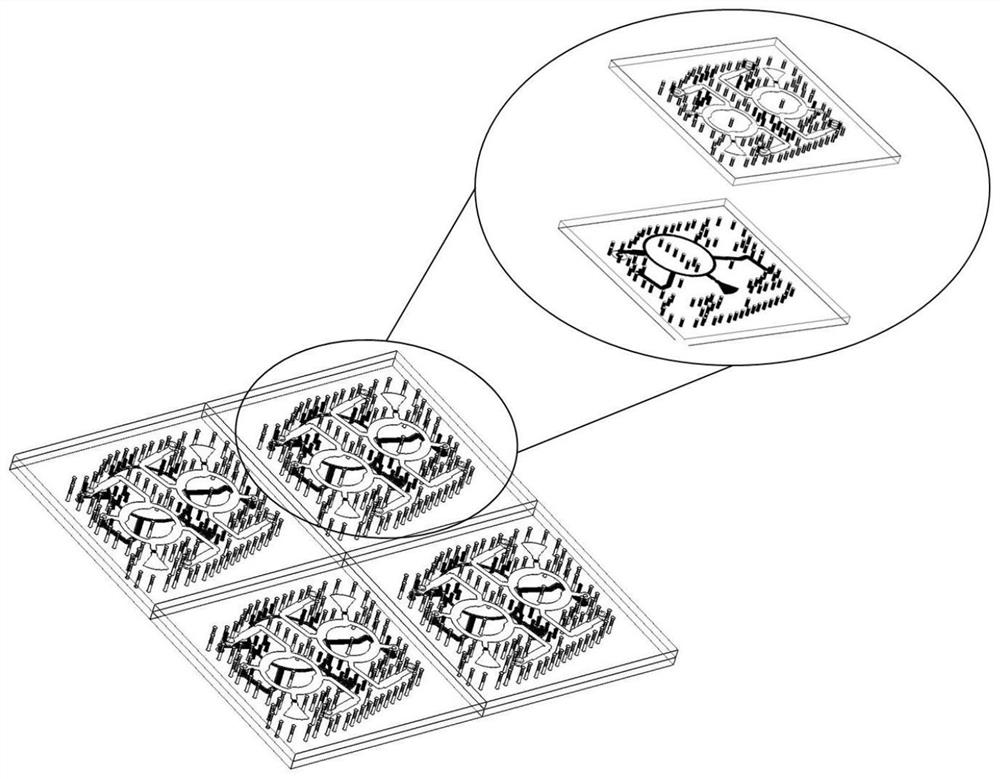

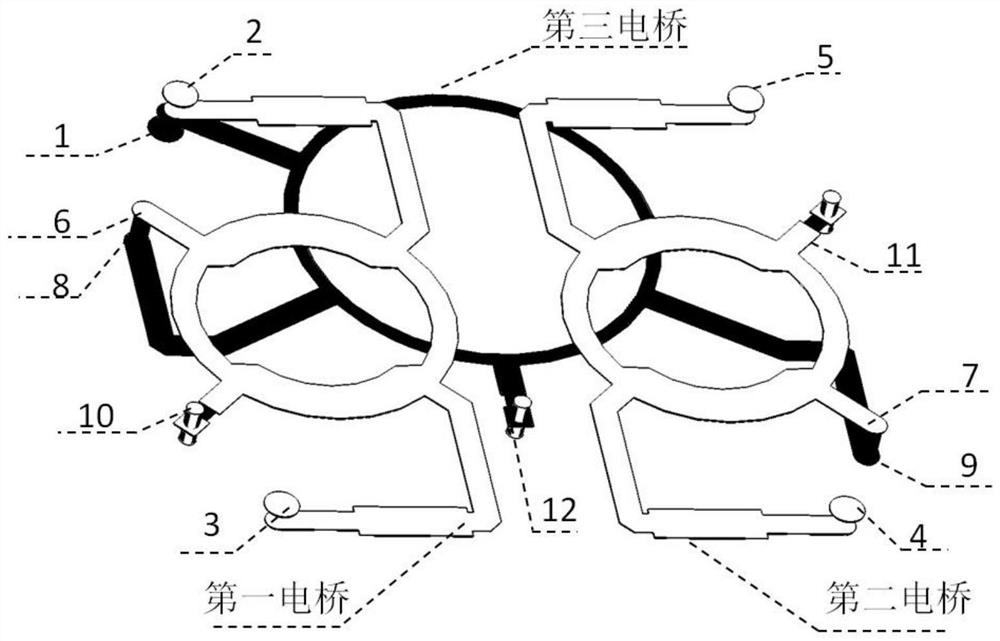

[0042] This embodiment is an antenna feeding network system based on the multi-layer mixed-voltage buried resistance technology and the high-density vertical interconnection technology PCB process: including a first electric bridge, a second electric bridge and a third electric bridge connected to each other to form upper and lower layers, etc. A transmission network and a four-in-one Wilkin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com