Mobile hydrogen service station

A technology of filling station and storage device, applied in the field of filling station, can solve problems such as external energy not being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

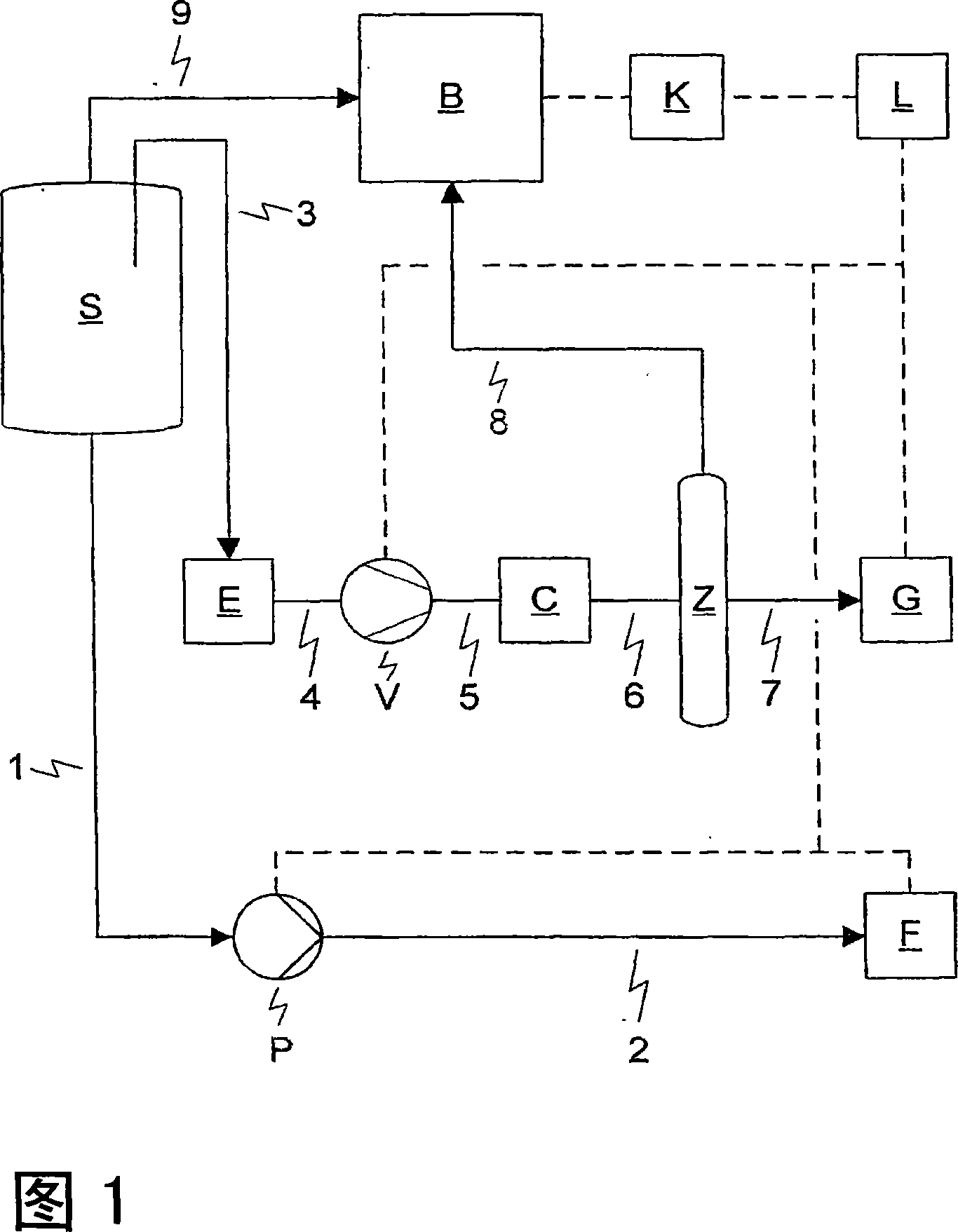

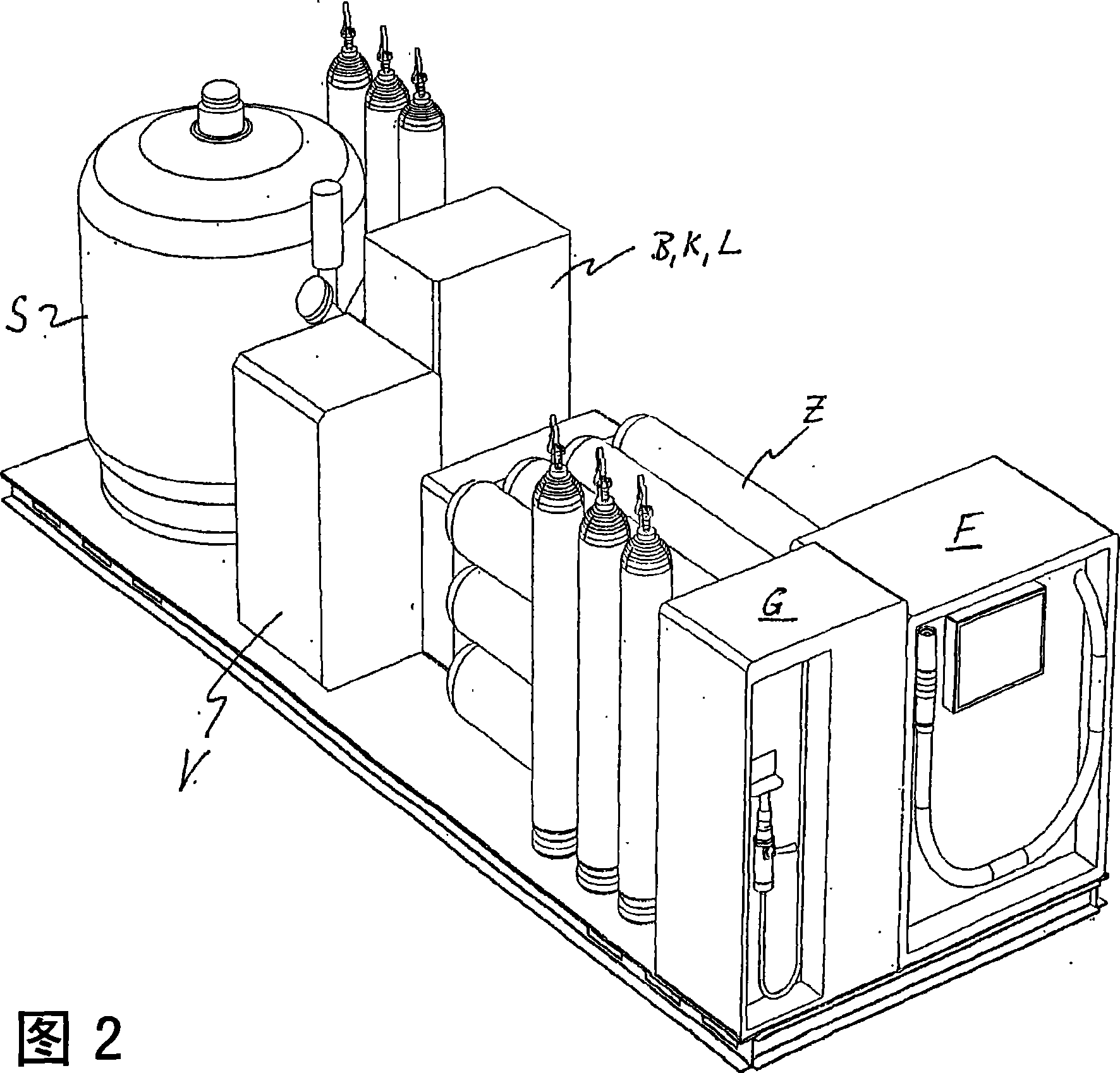

[0019] In this case, FIG. 1 shows a schematic diagram of a hydrogen filling station. The filling station has a storage device S for storing liquid hydrogen and usually has a capacity of up to 1000 liters of liquid hydrogen - this corresponds to about 786 Nm 3 .

[0020] Furthermore, two delivery units or distributors G and F are provided, via which gaseous hydrogen (discharge unit G) and liquid hydrogen (discharge unit F) can be delivered to the vehicle to be filled.

[0021] The delivery of liquid hydrogen from the storage device S to the delivery unit F takes place via line sections 1 and 2 in which (corresponding to the advantageous configuration of the filling station according to the invention) a suitable cryopump P can be arranged.

[0022] An evaporator E, a cryogenic compressor V, a heater C and an intermediate storage device Z are connected upstream of the gaseous hydrogen discharge unit G in the direction of flow. The evaporator E and / or the heater C are preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com