Air cycle refrigerating/cooling system and turbine unit used therefor

An air circulation and cooling system technology, applied in the direction of refrigerators, refrigeration and liquefaction, compressors, etc., can solve problems such as contact, and achieve the effect of high reliability and simple scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

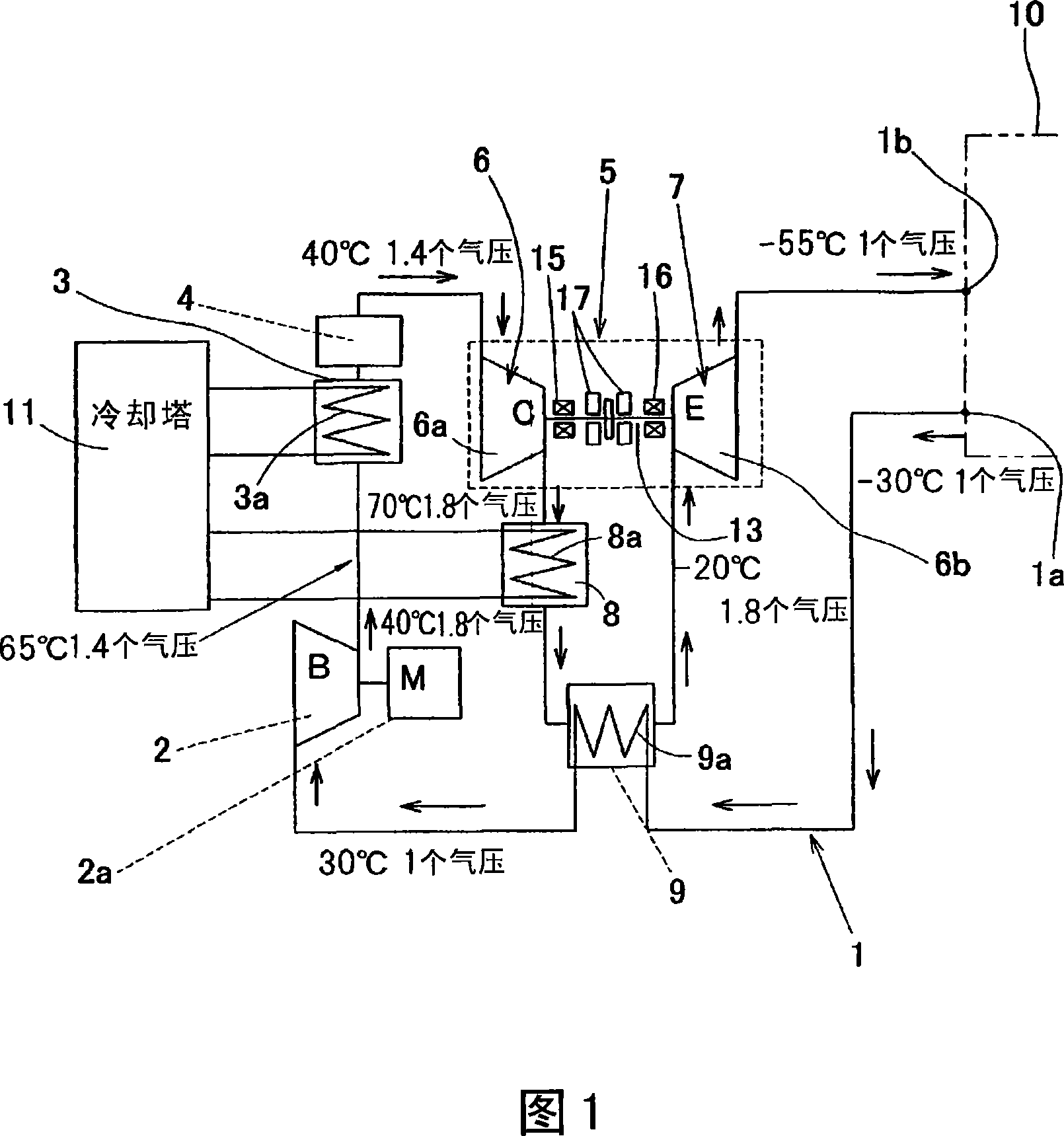

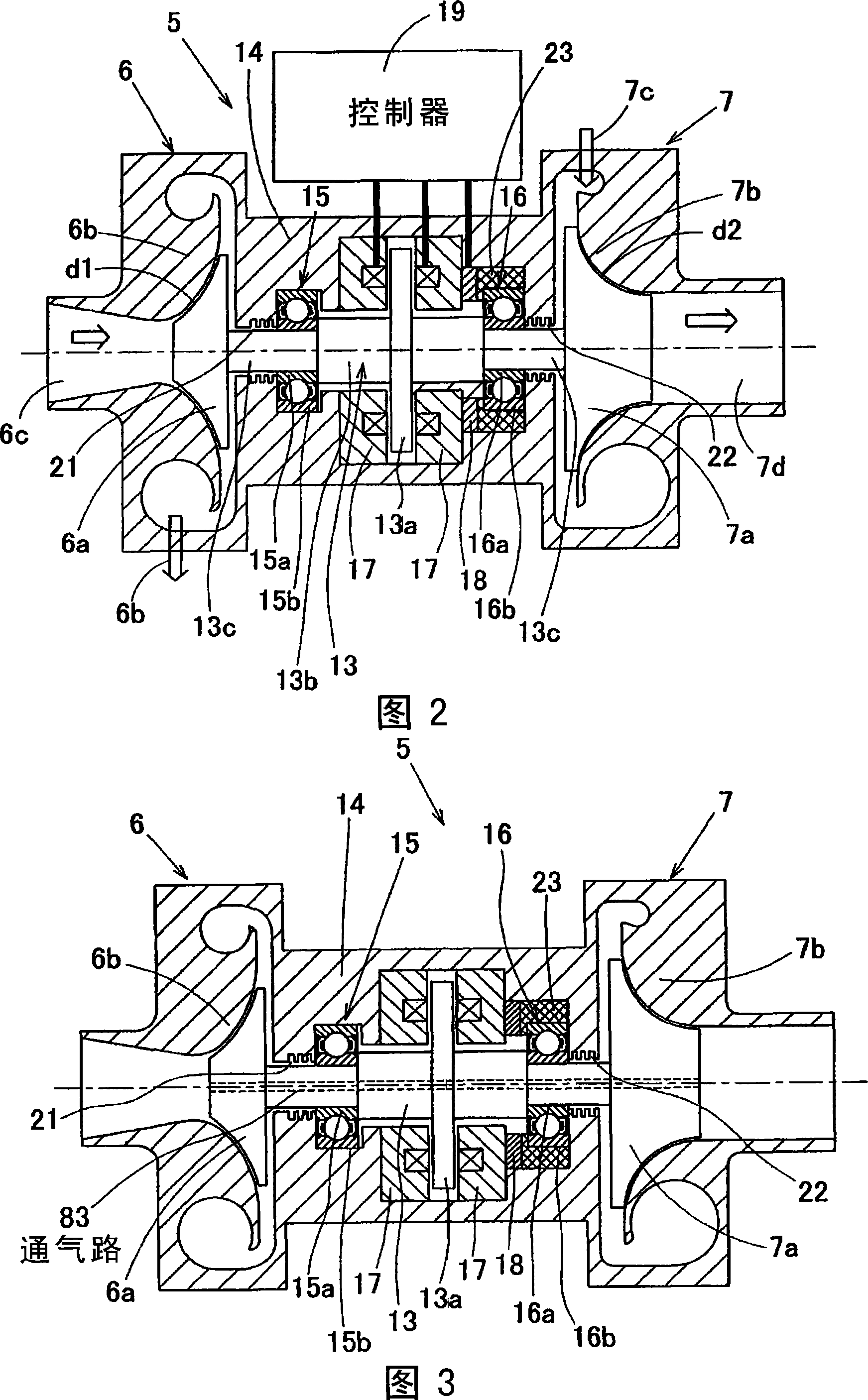

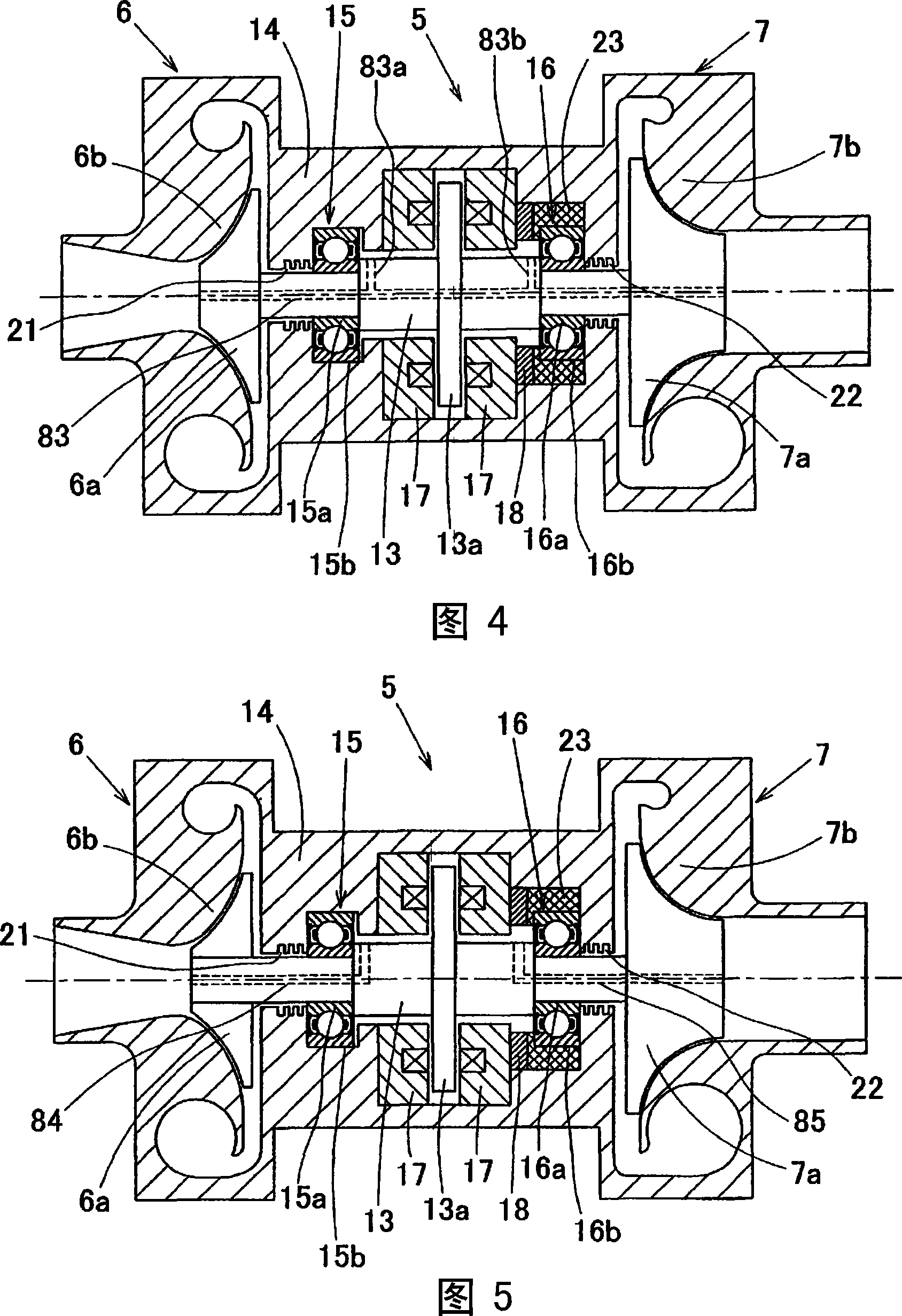

[0051] A first embodiment of the present invention will be described with reference to FIGS. 1 and 2 . FIG. 1 is a schematic view showing the overall air circulation refrigeration system. This air circulation refrigerating and cooling system is a system that directly cools air in a space to be cooled 10 such as a freezer as a refrigerant, and has an air circulation system that extends from an air inlet 1a opened in the space to be cooled 10 to an air outlet 1b. Access 1. In this air circulation passage 1, a pre-compression mechanism 2, a first heat exchanger 3, a dehumidifier 4, a compressor 6 of a steam turbine assembly 5 for air circulation refrigeration and cooling, a second heat exchanger 8, and an intermediate heat exchanger are arranged in this order. 9. The expansion steam turbine 7 associated with the steam turbine assembly 5 above. The intermediate heat exchanger 9 is inside the above-mentioned air circulation passage 1, and performs heat exchange between the inflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com